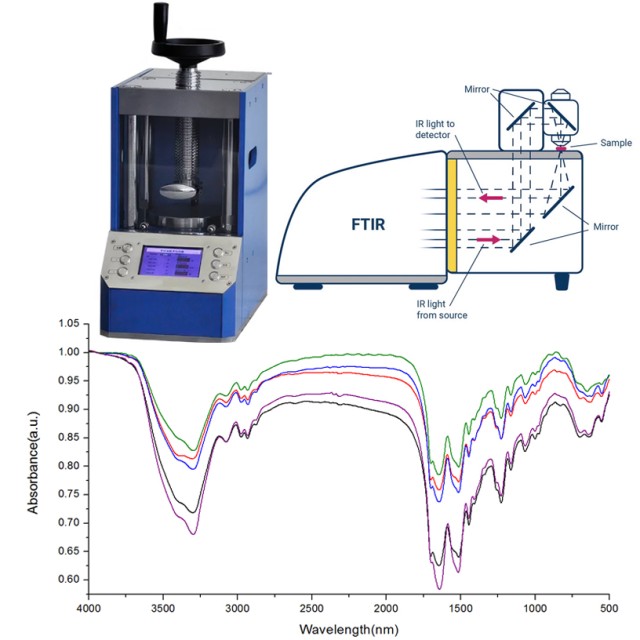

Introduction to FTIR Pellet Press

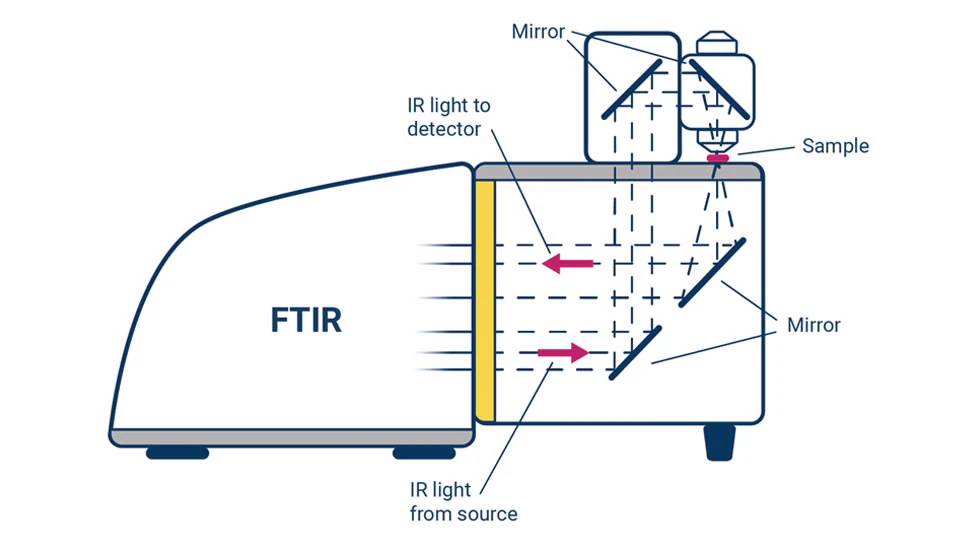

Fourier Transform Infrared (FTIR) spectroscopy is a non-destructive analytical technique used to identify and quantify the chemical composition of a sample. FTIR pellet presses are used to prepare solid samples for FTIR analysis by compressing them into pellets. The pellets help to reduce the sample’s scattering and increase the sample’s optical path length, which results in a better signal-to-noise ratio. FTIR pellet presses come in different types, including manual and automatic presses. Choosing the right type of press depends on the specific application and the required sample throughput.

Table of Contents

Advantages of using a pellet press

A pellet press is a laboratory equipment used for the preparation of pellets that are analyzed by Fourier Transform Infrared Spectroscopy (FTIR). Here are some of the advantages of using a pellet press:

Wider range of sample analysis

One of the key benefits of using a pellet press is that it enables the analysis of a wider range of samples. This includes small or difficult-to-handle samples, as well as materials that are not soluble or require specialized sample preparation techniques. By compressing a small amount of sample material into a pellet, a pellet press makes it possible to analyze a wide range of materials, including polymers, pharmaceuticals, minerals, and more.

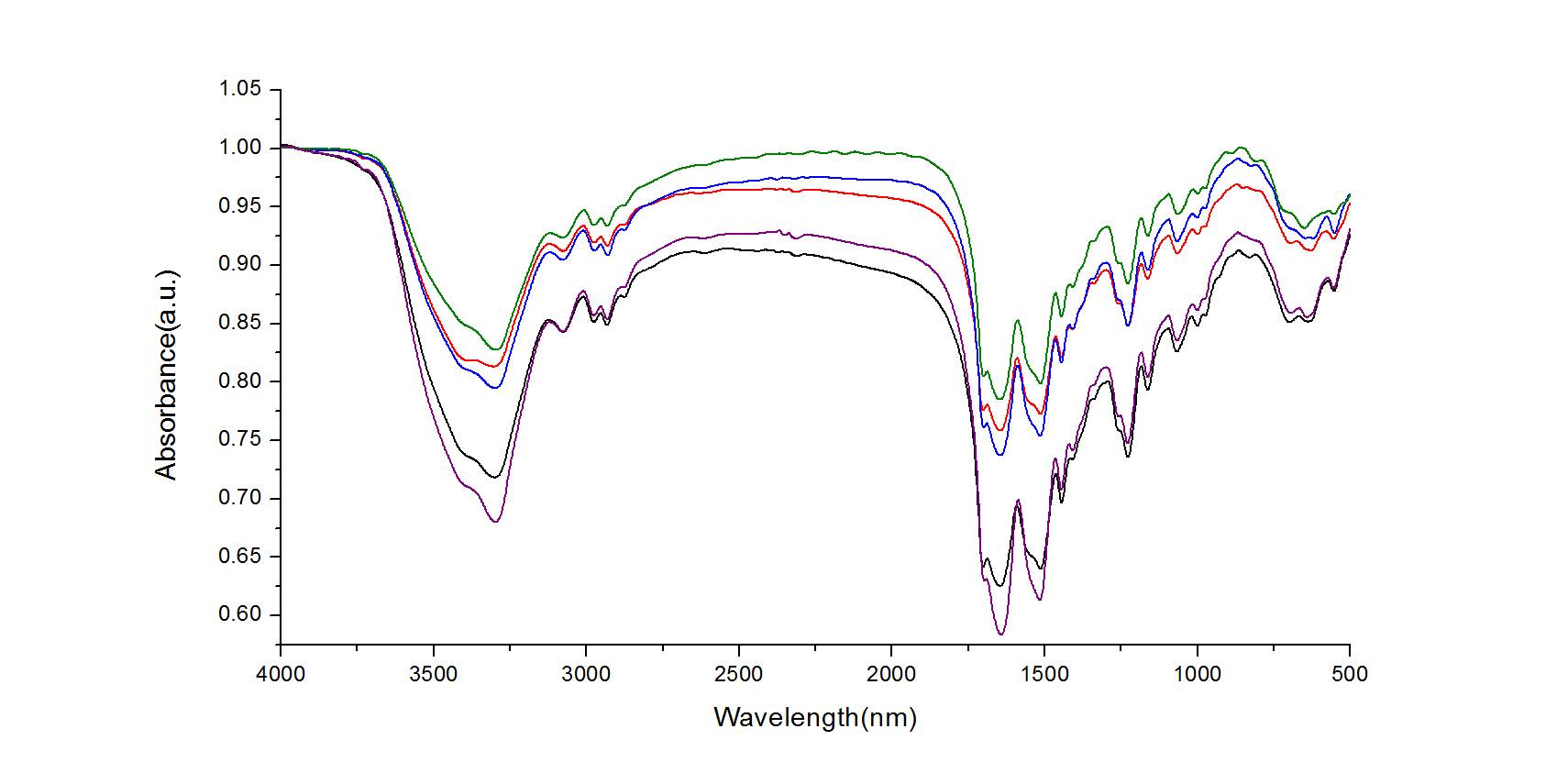

Increased sensitivity and accuracy of results

Another advantage of using a pellet press is the increased sensitivity and accuracy of results. By compressing the sample into a solid pellet, a pellet press reduces the interference from atmospheric gases and water vapor, which can affect the accuracy of FTIR analysis. This results in more reliable and accurate data, which is essential for many laboratory applications.

Time and cost savings

Using a pellet press can also reduce the time and cost associated with sample preparation, making it an essential tool in the laboratory. Pellet presses are typically easy to use and require minimal preparation time, allowing technicians to produce high-quality samples more quickly and efficiently. This can help to reduce the overall cost of laboratory analysis, while increasing the throughput of samples.

Improved sample handling

Finally, a pellet press can improve the handling of samples, making it easier to analyze them accurately. By compressing the sample into a solid pellet, a pellet press reduces the risk of contamination or loss of sample material, ensuring that the analysis is as accurate as possible. This is especially important for small or delicate samples, which can be difficult to handle in other ways.

In summary, there are several key advantages of using a pellet press in the laboratory. These include the ability to analyze a wider range of samples, increased sensitivity and accuracy of results, time and cost savings, and improved sample handling. For these reasons, a pellet press is an essential tool for any laboratory that uses FTIR spectroscopy.

How to Choose the Right Pellet Press

When it comes to selecting the right FTIR Pellet Press, there are several key factors to consider to ensure that you achieve accurate and consistent results. Here are some steps to follow when choosing the right pellet press for your needs:

Step 1: Determine the Sample Type and Required Pressure

The type of sample you are analyzing and its size can determine the force needed to compress it into a pellet, so it's important to choose a press with an appropriate pressure range. For instance, foodstuff samples may require a low load, whereas pharmaceutical products may need a higher load to make the sample bind. Mineral ores and fillers used in industrial manufacturing may require a higher load of 25 tons upward.

Step 2: Consider the Pellet Diameter and Material of the Die

The diameter of the pellets can affect the signal-to-noise ratio and the spectral resolution, so it's advisable to select a press that can produce pellets with a consistent and precise size. Pellets for FTIR are typically required to be within 3 mm up to 13 mm, the exact diameter will depend on the manufacturer of your FTIR equipment. The material of the die should also be compatible with the sample and the pressure to avoid contamination or damage to the sample or the press.

Step 3: Evaluate Ease of Use, Durability, and Cost

Other factors to consider when selecting a pellet press include the ease of use, durability, and cost of the press. The lowest cost hydraulic XRF presses are the manual type, but they may require a lot of effort to achieve the required load. Alternatively, power-operated presses offer consistency and repeatability. Basic power-operated presses offer a load range that can be adjusted by the user, and programmable presses offer a timer capability to offer maximum consistency, auto top-up, and a step function.

Step 4: Check the Quality of XRF Pellet Die

All dies should be constructed from high-quality stainless steel, and the pressing face used to contact the sample as it is pressed should be perfectly flat and smooth, commonly polished to a mirror finish. If iron is to be analyzed in the sample, there is the option to use Tungsten Carbide die pellets to avoid contamination of the sample.

Step 5: Ensure Correct Load for XRF Pellet Pressing

The pressing procedure can be simply described as a load applied to the sample to compress it so that the powder will bind and form a solid pellet. If a sample does not bind at all or breaks up very easily, even when supported in a cup, adding a wax binder at the milling stage may be considered. The wax binder is available in powder or tablet form, and there are no set rules as to how much to add, but this should be the minimum amount to safely bind the sample when pressed.

By following these steps and carefully considering the various factors involved, you can select the right FTIR Pellet Press that meets your specific needs. Overall, choosing the right pellet press can improve the quality and efficiency of spectroscopic analysis and enhance the accuracy and reliability of scientific research.

Factors to Consider When Pressing Pellets

Sample Type

Different samples have varying properties, such as hardness and moisture content, which can affect pellet quality. It is essential to consider the type of sample being pressed to ensure accurate and precise results.

Pressure

The amount of pressure applied during pellet pressing is crucial. Too little pressure can result in loose and weak pellets, while too much pressure can cause sample deformation. It is recommended to apply 25-35T of pressure for 1-2 minutes to ensure no void spaces are present in the pellet.

Size and Shape of the Pellet

The size and shape of the pellet also play a significant role in the analysis, as they can affect the path length of the infrared beam. It is important to use a pellet press that allows for adjustable pellet size and shape.

Material of the Pressing Die

The die material can affect the pellet surface finish and can also interact with the sample, leading to contamination. It is essential to use high-quality pressing dies made from materials such as hardened steel or diamond.

Particle Size

Producing pressed pellets requires accuracy and specific measurements, and pelletizing works well when samples are ground to a particle size of <50µm, although <75µm is also acceptable. Working with small particle sizes is important because this impacts how well the sample binds together under pressure, which impacts the analytical results.

Thickness

Aside from particle size, the thickness of pressed pellets is also crucial for the effective analysis of a sample. If a sample is too thick, the X-rays will not be able to penetrate it up to a certain point. Because XRF analysis relies on emitted X-rays reaching the detector, the sample must be infinitely thick to the X-rays.

Binder

During the pelletizing process, powders must be mixed with a binding agent to bind together correctly. Using the most suitable binder for your sample will hold the powders together and reduce the risk of loose powders breaking away. A cellulose/wax mixture is typically used, and a large amount of binder is used for most samples to avoid weak pellets that can break, damaging the instrument and destroying a sample.

Contamination

Contamination is most likely to occur during the grinding process, which can lead to inaccurate results. To avoid contamination, external components from the sample preparation instrument should not be passed into the sample, and samples should be thoroughly cleaned between analyses.

Dilution

The amount of binder used must stay the same for every sample to ensure accuracy levels and avoid over-diluting a sample. The most common sample dilution ratio is 20/30% binder to sample ratio is recommended.

Molding Polymer Films

Analysis of polymers using spectroscopic techniques often requires a thin film to be produced. This can be achieved with heat and pressure using a heated platen and a film-making mold to set the thickness exactly.

Pelleting Powder Samples

The purpose of pressing powder samples is to create a solid material that does not fall apart after the removal of the load. The load required to achieve a fully bonded pellet depends greatly upon the materials involved. The required pressure for compaction can also depend on things like moisture content, particle size and distribution, and overall homogeneity of the materials.

Particle Size and Pressure Requirements

FTIR Pellet Press is an essential tool used to prepare disk-shaped solid samples for FTIR analysis. To ensure uniformity in the sample, the particle size plays a crucial role. The particle size should be small, typically around 10 micrometers. It is important to note that the pressure applied during the pressing process should be high enough to create a uniform pellet without causing damage to the instrument.

Importance of Particle Size

The particle size requirement is critical when using an FTIR Pellet Press. The sample's particle size should be small enough to ensure uniformity in the sample. The smaller the particle size, the more uniform the sample's pellet will be. FTIR Pellet Press can compress and bind small particles into a homogeneous disk or pellet for spectroscopic analysis.

Pressure Requirements

The pressure requirements play an equally important role as that of particle size. The pressure applied during the pressing process should be high enough to create a uniform pellet without causing damage to the instrument. Generally, a pressure of 10-20 tons is recommended for most samples. The pressure and temperature should be maintained at a constant rate to produce uniform pellets.

Process of FTIR Pellet Press

FTIR Pellet Press is highly efficient in preparing samples for analysis. It is suitable for analyzing solid, liquid, and powder samples, making it an indispensable tool for laboratory analysis. The process of creating a pellet involves filling the sample into a pellet die and then placing it in the press. The press applies pressure to the die, which compresses the sample into a pellet. The pressure should be applied gradually to prevent any damage to the instrument.

Conclusion

In conclusion, understanding the particle size and pressure requirements when using an FTIR Pellet Press is essential to obtaining accurate and reliable results in FTIR spectroscopy. Particle size and pressure requirements play a crucial role in preparing samples for analysis. Therefore, it is important to maintain a constant pressure and temperature to produce uniform pellets. FTIR Pellet Press is a highly efficient tool that is suitable for analyzing solid, liquid, and powder samples, making it an indispensable tool for laboratory analysis.

Choosing a high-quality XRF pellet die

When it comes to sample preparation for FTIR spectrometers, the pellet press is an essential tool that is used to create solid pellets from powdered samples. The quality of the XRF pellet die used in the pellet press is crucial in obtaining accurate and precise results. There are several factors to consider when selecting a pellet die, such as the die material, die diameter, and die thickness.

Die Material

The material used for the pellet die is an important factor to consider when selecting a high-quality XRF pellet die. Steel dies are the most economical option, but they can be prone to wear and tear over time. Tungsten carbide dies are more durable than steel dies, making them ideal for high-volume use. Diamond dies are the most expensive but offer the highest level of precision and accuracy.

Die Diameter and Thickness

The diameter and thickness of the die also play a role in the final pellet quality. A larger diameter die can create thicker pellets, while a thinner die can create thinner pellets that may be more suitable for certain applications. The thickness of the die can affect the packing density of the sample, which can impact the accuracy of the results.

Consider the Sample Type

It is also important to consider the type of sample being analyzed when selecting a high-quality XRF pellet die. Some samples may require the use of a specific type of die material or a certain die diameter and thickness to achieve the desired level of accuracy.

Pellet Die Maintenance

Regular maintenance of the pellet die is necessary to ensure consistent and accurate results. It is important to clean the die regularly to prevent contamination and to inspect it for any signs of wear and tear. Proper storage of the die, such as using a protective case, can also help prolong its lifespan.

Conclusion

Choosing a high-quality XRF pellet die is essential for achieving accurate and precise results when using an FTIR pellet press. When selecting a pellet die, it is important to consider the material, diameter, and thickness of the die to ensure that it meets your specific needs and requirements. Regular maintenance of the pellet die is also necessary to ensure consistent and accurate results. By following these guidelines, you can ensure that you are using a high-quality XRF pellet die that will provide reliable results for your FTIR analysis.

Manual vs automatic XRF pellet press

XRF (X-ray fluorescence) analysis is a common method used in material analysis, and a pellet press is an essential tool for preparing samples for this analysis. When it comes to XRF pellet presses, there are two types: manual and automatic.

Manual XRF pellet press

Manual XRF pellet presses require more labor and time, as users must manually apply pressure to create the pellets. However, they are more affordable and can be a good option for smaller labs or those on a budget. Manual presses are also available in various sizes and capacities, making them suitable for both small-scale and large-scale testing.

To operate a manual XRF pellet press, a cylinder filled with hydraulic oil supplies pressure to a moving piston. Users apply pressure using a hand-operated pump to compress the material, which is placed on the piston. Powder materials are usually contained in a pellet die which causes the compressed powder to form a solid disc of material. While manual presses can be more laborious, they are still an effective option for labs that require infrequent pellet pressing.

Automatic XRF pellet press

Automatic XRF pellet presses, on the other hand, are quicker and easier to use, as they apply pressure automatically. They are also more expensive than manual presses, but can be a worthwhile investment for labs that require frequent pellet pressing. Some automatic presses also have additional features, such as the ability to adjust the pressure or temperature, which can improve the quality of the pellets.

Automatic XRF pellet presses often improve the workflow in busy laboratories, as – once the press is programmed – it can operate autonomously, allowing the technician to get to work on other tasks. They're also more accurate and consistent, due to the lack of variable factors during use. Available in 30, 40, and 60 tonne configurations, automated presses are suitable for frequent pressing work and are often used for industrial XRF applications and other laboratory sample manipulation activities.

Which one to choose?

Choosing the right type of press depends on the specific needs of the lab and the type of analysis being conducted. Both manual and automatic options have their advantages and disadvantages, and it is up to the user to determine which one is the best fit for their laboratory.

For some labs, manual XRF pellet presses present an advantage over automatic equivalents. This is mostly due to price; if you aren’t paying for electronically powered equipment, you’ll likely be paying less. However, if your workflow relies on pressed samples and your lab staff will need to produce them recurrently, they might find a manual XRF pellet press to be quite laborious. In these instances, an automatic XRF pellet press will likely be more convenient and enable a quicker pace of work.

In summary, both manual and automatic XRF pellet presses have their place in material analysis. The decision to choose one over the other will depend on the specific needs of the lab and the frequency of pellet pressing required.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Related Articles

- Guide for Xrf Pellet Press

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Automated laboratory XRF and KBR pellet press operating procedures

- Understanding Cold Isostatic Pressing (CIP) and Its Advantages

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method