The Illusion of the Average

Picture a utility-scale boiler. It's a colossal inferno, consuming tons of pulverized coal or biomass every hour. Inside is a chaotic, turbulent world of fire and pressure.

From the outside, we measure outputs—megawatts, emissions, efficiency. We see the system as a whole and tend to think in averages. The average temperature, the average fuel consumption, the average residence time.

But in complex systems, the average is often a misleading fiction. The real story, the one that governs efficiency and unlocks innovation, is not found in the average. It's found in the journey of a single, individual particle as it tumbles through the fire.

The fundamental engineering challenge is this: How do you isolate and study one particle's experience in a system of millions?

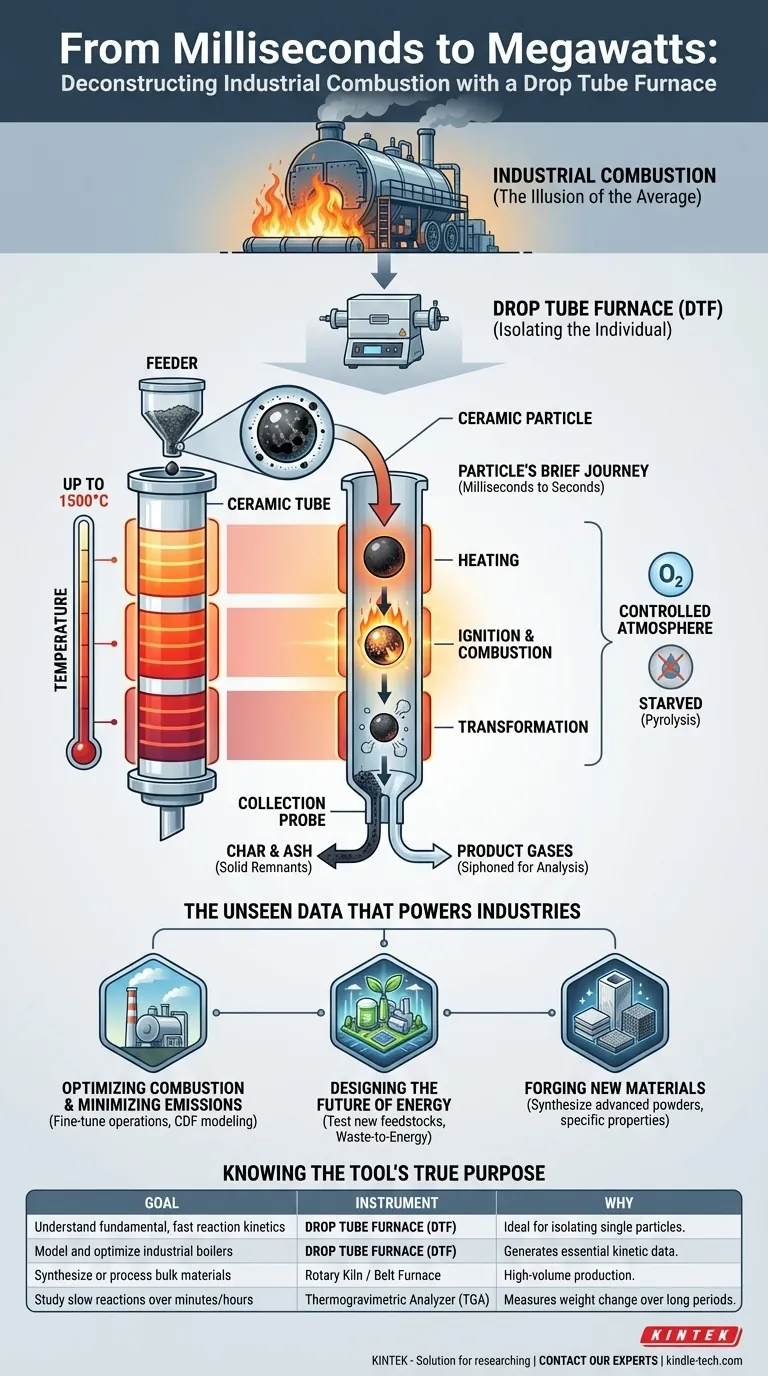

Isolating the Individual: The Engineering of a Drop Tube Furnace

The answer is an elegant piece of laboratory engineering: the Drop Tube Furnace (DTF). It is not a tool for bulk processing; it is a microscope for high-temperature reactions. It strips away the chaos of an industrial reactor to reveal the fundamental physics and chemistry at play.

A Controlled Fall Through Fire

At the heart of the DTF is a vertical ceramic tube, capable of withstanding extreme temperatures, often exceeding 1500°C. This tube is not just a hot pipe; it's a meticulously controlled environment. Multiple, independent heating zones allow researchers to create a precise temperature profile that a particle would experience in a full-scale boiler.

This is the stage where the experiment happens.

The Particle's Brief, Violent Journey

A sophisticated feeder at the top introduces a tiny, metered stream of sample particles. Gravity takes over. For a few brief moments—from milliseconds to a few seconds—the particle is in freefall through the furnace's controlled atmosphere.

This journey mimics the violent life of a fuel particle in an industrial system. In this short residence time, it heats up, ignites, combusts, and transforms. We can precisely control the gas around it, simulating everything from the oxygen-rich environment of a boiler (combustion) to the oxygen-starved conditions of a gasifier (pyrolysis and gasification).

Capturing the Aftermath

At the bottom, a collection probe rapidly quenches the reaction, freezing the particle in time. The solid remnants—char and ash—are collected. The product gases are siphoned off for analysis.

This aftermath is not waste; it is data. It is the complete story of what happened to that single particle during its journey.

The Unseen Data That Powers Industries

This particle-level data is not merely academic. It is the bedrock upon which industrial processes are optimized and new technologies are built.

-

Optimizing Combustion, Minimizing Emissions: By understanding how quickly a specific biomass char burns out or how much NOx is formed from a type of coal, engineers can fine-tune boiler operations for maximum efficiency and minimal pollution. The DTF provides the exact parameters needed for accurate computational fluid dynamics (CFD) modeling.

-

Designing the Future of Energy: When developing waste-to-energy or advanced biofuel technologies, the DTF is indispensable. It allows scientists to test the gasification potential of new feedstocks quickly and affordably, predicting how they will behave before investing millions in a pilot plant.

-

Forging New Materials: The controlled temperature and atmosphere are perfect for synthesizing advanced materials. Processes like calcination or ore roasting can be studied at the micro-level to produce ceramic powders or metals with highly specific properties.

Knowing the Tool's True Purpose

The human mind has a bias to use a familiar tool for every problem. But the power of an instrument like the Drop Tube Furnace lies in knowing exactly what it is for—and what it is not.

A DTF offers an idealized view. It cannot replicate the complex particle-to-particle interactions of a dense fluidized bed. Its gravity-dependent residence time is inherently short, making it unsuitable for reactions that take minutes or hours.

To make an informed choice, you must align the tool with the question you are asking.

| Your Primary Goal | Recommended Instrument | Why |

|---|---|---|

| Understand fundamental, fast reaction kinetics at the particle level. | Drop Tube Furnace (DTF) | Ideal for isolating single particles in a controlled environment. |

| Model and optimize industrial boilers or gasifiers. | Drop Tube Furnace (DTF) | Generates the essential kinetic data for accurate simulations. |

| Synthesize or process bulk materials. | Rotary Kiln / Belt Furnace | Designed for continuous, high-volume production. |

| Study slow reactions over minutes or hours. | Thermogravimetric Analyzer (TGA) | Measures weight change over long periods with high precision. |

Understanding this distinction is key. The DTF is a powerful analytical instrument, a window into the fundamental events that, when multiplied by billions, power our world.

This level of granular analysis isn't just academic; it's the foundation of industrial efficiency and innovation. At KINTEK, we provide the precision-engineered drop tube furnaces that bridge the gap between a single particle and a power plant. To generate the critical data needed for your research, you need the right tool. Contact Our Experts

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

- Installation of Tube Furnace Fitting Tee

- The Silent Partner in Pyrolysis: Engineering the Perfect Thermal Boundary

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- Your Tube Furnace Is Not the Problem—Your Choice of It Is