The isostatic press, a cornerstone in the world of materials processing, relies on seamless functionality to produce components of unparalleled quality. Amidst its intricate design, the replacement of a seemingly humble component—the rubber ring—takes center stage. Unveiling the nuances of this crucial procedure is not just a technical necessity; it's a journey into the meticulous care required to maintain the precision of the isostatic press. Let's explore the steps involved in replacing the rubber ring and the vital considerations that can make all the difference.

Replacing the rubber ring of isostatic press

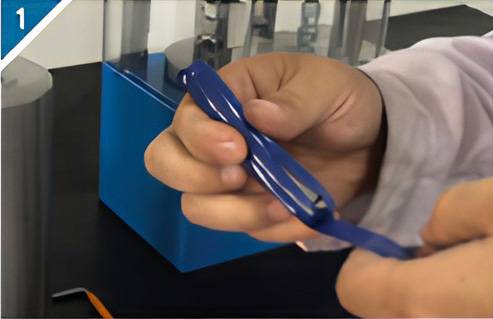

1.Put the sample into a rubber mold and seal it.

2.Place the assembled rubber mold into the isostatic cavity.

3.Place the pressure rod of the isostatic pressure chamber into the chamber.

4.Tighten the air release valve on the pressure rod.

5.Place the chamber into the tablet press.

6.Tighten the oil drain valve stem.

7.Rock the handle to apply pressure to the desired pressure.

8.Keep the pressure for a while.

9.Loosen the oil drain valve stem.

10.Release the screw after the pressure is released.

11.Remove the isostatic chamber.

12.Loosen the bleed valve on the chamber.

13.Use the disassembly screw on the pressure rod of the chamber to release pressure from the pressure rod on the chamber.

14.Remove the isostatic pressure lever.

15.Remove the mold from the cavity.

16.Remove the sample.

Precautions for isostatic press

Problem 1: Deformation of rubber ring.

When the isostatic pressure chamber is used for a long time, the rubber ring in the chamber must be replaced regularly to avoid oil leakage from the rubber ring.

Question 2: Hydraulic oil.

It is advisable to use clean No. 46 anti-wear hydraulic oil for the isostatic tablet press. If the color turns black or there are many particles, it needs to be replaced in time.

Problem 3: The cavity is deflated.

Before pressurizing the isostatic cylinder, the air in the cavity must be purged before normal pressurization can occur. In order to avoid the required pressure in the cavity after air compression.

Question 4: Close the protective door.

When pressurizing, be sure to close the protective door first and then pressurize to prevent the hydraulic oil in the chamber from leaking and injuring the operator.

Question 5: Align the cavity.

The isostatic pressure chamber must be aligned and on the same axis as the screw cylinder to ensure that the pressure acts vertically on the isostatic pressure chamber.

Question 6: Cylinder stroke.

The stroke of the oil cylinder of the isostatic tablet press should generally not exceed 50mm to avoid the deformation of the tension spring causing the piston to be unable to return.Conclution

In the realm of materials processing, the isostatic press is a testament to the marriage of innovation and reliability. As we navigate through the steps of replacing the unassuming rubber ring, we uncover the significance of this seemingly minor task. Attention to detail is not merely a procedural requirement but a commitment to the excellence that defines the isostatic press. In the symphony of precision, the careful replacement of the rubber ring becomes a note of assurance, ensuring that each press yields results of the highest caliber. With this understanding, we pave the way for continued excellence in materials processing, where every replacement is a step toward sustaining the impeccable legacy of the isostatic press.

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Isostatic Molding Pressing Molds for Lab

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing