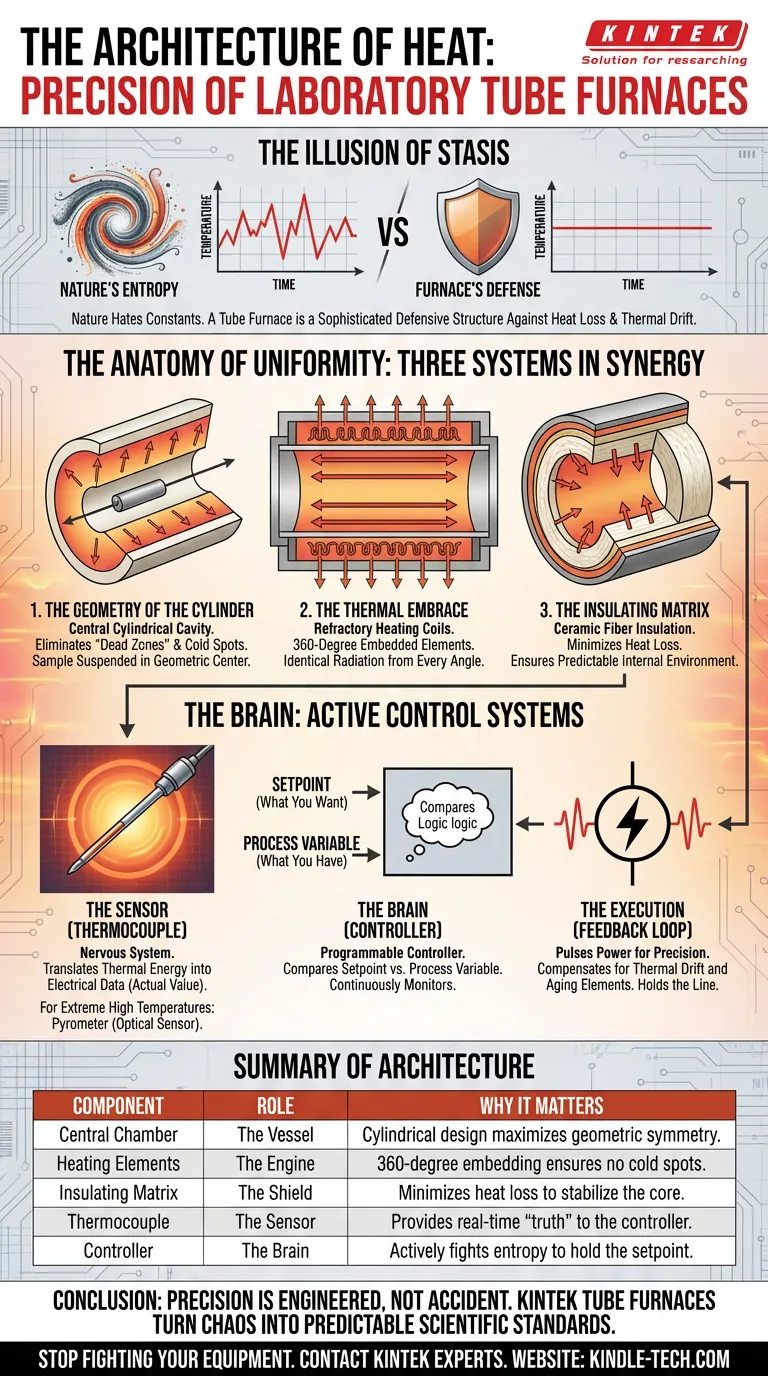

The Illusion of Stasis

In any scientific endeavor, we crave constants. We want variables to remain fixed so that when we change one thing, we know exactly what caused the result.

But nature hates constants. Nature loves entropy.

Nowhere is this battle more evident than in high-temperature material processing. When you set a furnace to 1000°C, you aren't creating a static environment. You are initiating a dynamic war against heat loss, thermal drift, and environmental fluctuations.

The laboratory tube furnace is not merely a box that gets hot. It is a sophisticated defensive structure designed to hold that line.

It is a machine built with a singular, obsessive purpose: to create a cylindrical zone of perfect thermal uniformity where the chaos of the outside world cannot enter.

The Anatomy of Uniformity

If you dissect a tube furnace, you find that its effectiveness isn't magic. It is the result of three systems working in total synergy.

1. The Geometry of the Cylinder

The central chamber is cylindrical for a reason. Corners are where uniformity goes to die; they create cold spots and airflow eddies.

By using a central cylindrical cavity made of high-temperature ceramics, the furnace eliminates "dead zones." The sample sits suspended in the geometric center, the most protected point in the system.

2. The Thermal Embrace

Surrounding this ceramic heart are refractory heating coils.

In cheaper designs, heat comes from one or two sides. In a high-quality tube furnace, these elements are embedded within the ceramic walls, wrapping the chamber in a 360-degree embrace. This ensures that the radiation hitting your sample is identical from every angle.

3. The Insulating Matrix

Heat wants to escape. It flows from hot to cold. To stop this, the heating assembly is encased in a thermal insulation matrix, often made of ceramic fiber.

This isn't just about energy efficiency. It is about stability. By minimizing the rate of heat loss, the insulation ensures that the internal environment remains predictable.

The Brain: Active Control Systems

Structure provides the potential for uniformity, but the control system delivers it.

Achieving a specific temperature is not a passive act. It requires a continuous, millisecond-by-millisecond conversation between three components.

The Sensor (The Thermocouple)

The thermocouple is the nervous system. It sits inside the chamber, exposed to the inferno, translating thermal energy into electrical voltage. It provides the "actual" data.

Note: For extreme temperatures where a thermocouple might fail, advanced systems switch to a pyrometer, an optical sensor that measures heat from a distance.

The Brain (The Controller)

The programmable controller receives the data from the thermocouple. It compares two numbers:

- The Setpoint (What you want).

- The Process Variable (What you have).

The Execution

If the temperature is 0.1°C too low, the controller pulses power to the elements. If it is too high, it cuts power.

This feedback loop handles the "thermal drift." Over time, heating elements age. Their resistance changes. A dumb heater would simply get cooler over time. A tube furnace with a feedback loop notices the drop and pumps in more voltage to compensate.

The Trade-offs of Precision

Engineering is the art of trade-offs.

To get this level of control—where temperature rise and fall rates are programmable and repeatable—you sacrifice simplicity and low cost.

A standard muffle furnace is cheaper. But a muffle furnace is a blunt instrument. A tube furnace is a scalpel. You are paying for the elimination of variables. You are paying for the assurance that the 1000°C you used today is the exact same 1000°C you will use next year.

Summary of Architecture

| Component | Role | Why it Matters |

|---|---|---|

| Central Chamber | The Vessel | Cylindrical design maximizes geometric symmetry. |

| Heating Elements | The Engine | 360-degree embedding ensures no cold spots. |

| Insulating Matrix | The Shield | Minimizes heat loss to stabilize the core. |

| Thermocouple | The Sensor | Provides real-time "truth" to the controller. |

| Controller | The Brain | Actively fights entropy to hold the setpoint. |

Conclusion

The tube furnace is a testament to the idea that precision is not an accident. It is engineered.

Whether you are focusing on process repeatability, sample uniformity, or high-temperature stability, the equipment you choose defines the limits of your data.

At KINTEK, we understand that your research depends on the suppression of variables. Our tube furnaces are built with the robust insulation and responsive feedback loops necessary to turn a chaotic physical process into a predictable scientific standard.

Stop fighting your equipment and start trusting your results. Contact Our Experts to discuss the specific thermal architecture your laboratory needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

Related Articles

- Your Tube Furnace Is Not the Problem—Your Choice of It Is

- Beyond Heat: The Tube Furnace as a Controlled Micro-Environment

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures