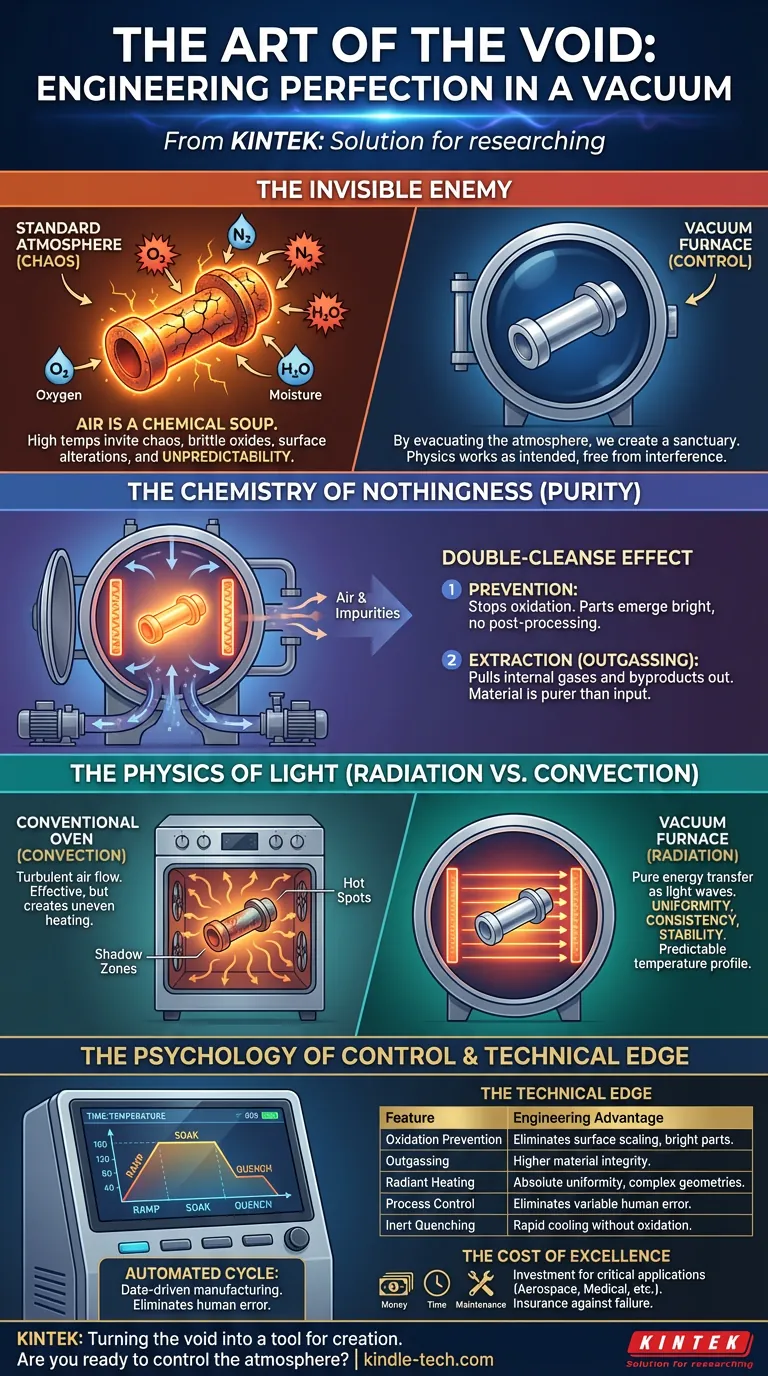

The Invisible Enemy

In the world of material science, air is not a neutral medium. It is a chemical soup.

When you heat a metal in a standard atmosphere, you are inviting chaos into the process. Oxygen, nitrogen, and moisture are aggressive actors. At high temperatures, they don't just surround the material; they attack it. They form brittle oxides. They alter surface chemistry. They introduce the one thing an engineer fears most: unpredictability.

To achieve perfection, you must first remove the variables.

This is the philosophy behind the vacuum furnace. It is not merely a tool for making things hot. It is a mechanism for control. By evacuating the atmosphere, we create a sanctuary where physics works exactly as we intend, free from the interference of nature.

The Chemistry of Nothingness

The primary argument for using a vacuum furnace is simple: Purity.

In a standard oven, heat acts as a catalyst for oxidation. The hotter the part gets, the faster a layer of scale forms on its surface. For a simple bracket, this might be acceptable. For a medical implant or an aerospace component, it is catastrophic.

A vacuum furnace creates a chemically inert environment by physically removing the air.

The Double-Cleanse Effect

The vacuum process works on two levels:

- Prevention: It stops oxygen from reaching the surface, ensuring the part emerges bright and clean, with no need for post-processing acid baths or scrubbing.

- Extraction: It actively pulls impurities out of the material. This is known as "outgassing." As the material heats up, trapped internal gases and manufacturing byproducts vaporize. The vacuum pumps immediately sweep these contaminants away.

The result is a material that is often purer than when it entered the chamber.

The Physics of Light: Radiation vs. Convection

How do you heat something when there is no air to carry the heat?

In a conventional oven, fans blow hot air over the part. This is convection. It is effective, but it is turbulent. It creates hot spots and shadow zones.

In a vacuum, convection is impossible. Instead, heat travels via radiation.

This is the engineer's romance: heat transferring as pure energy, light waves traveling from the heating elements directly to the workpiece. This physics dictates a superior outcome:

- Uniformity: Radiation heats the entire zone evenly.

- Consistency: There are no drafts or currents to cool edges prematurely.

- Stability: The temperature profile becomes predictable, critical for minimizing warping in complex geometries.

The Psychology of Control

Reliability is the absence of surprise.

In high-stakes laboratory and industrial settings, "good enough" is indistinguishable from failure. You need a process that produces the exact same result on the 100th run as it did on the first.

Modern vacuum furnaces, like the systems engineered by KINTEK, substitute human intuition for computer-driven precision.

The Automated Cycle

The operator does not guess. They program a cycle. The system manages:

- Ramp rates: How fast the temperature rises.

- Soak times: How long the temperature holds.

- Quenching: The rapid backfilling of inert gas (like argon or nitrogen) to cool parts instantly, locking in specific metallurgical hardness.

This is data-driven manufacturing. It turns heat treatment from an art form into a repeatable science.

The Cost of Excellence

We must be objective. Perfection has a price tag.

If you are annealing a cast iron fence post, a vacuum furnace is financial overkill. The technology requires investment.

The Constraints:

- Capital Cost: High-vacuum pumps and sealed chambers are complex engineering feats, making them more expensive than atmospheric ovens.

- Time: You cannot just open the door and throw a part in. You must wait for the chamber to pump down to a vacuum state.

- Maintenance: Seals must be tight. Pumps must be oiled. The system demands respect and care.

However, for critical applications, these are not costs; they are insurance premiums against failure.

Summary: The Technical Edge

For those deciding between atmospheric and vacuum processing, here is the breakdown of value:

| Feature | The Engineering Advantage |

|---|---|

| Oxidation Prevention | Eliminates surface scaling; parts emerge bright and clean. |

| Outgassing | Actively removes internal impurities for higher material integrity. |

| Radiant Heating | Ensures absolute temperature uniformity across complex geometries. |

| Process Control | Computerized cycles eliminate variable human error. |

| Inert Quenching | Allows for rapid cooling without oxidation risks. |

Conclusion

The vacuum furnace is a testament to the idea that sometimes, the best way to solve a problem is to remove everything else. By eliminating the atmosphere, we eliminate the error.

At KINTEK, we understand that for our clients—whether in aerospace, medical research, or advanced materials—the environment determines the outcome. Our vacuum furnaces are built to provide the ultimate control, turning the void into a tool for creation.

Are you ready to stop fighting the atmosphere and start controlling it?

Contact our experts today to discuss how KINTEK can bring precision to your laboratory.

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering