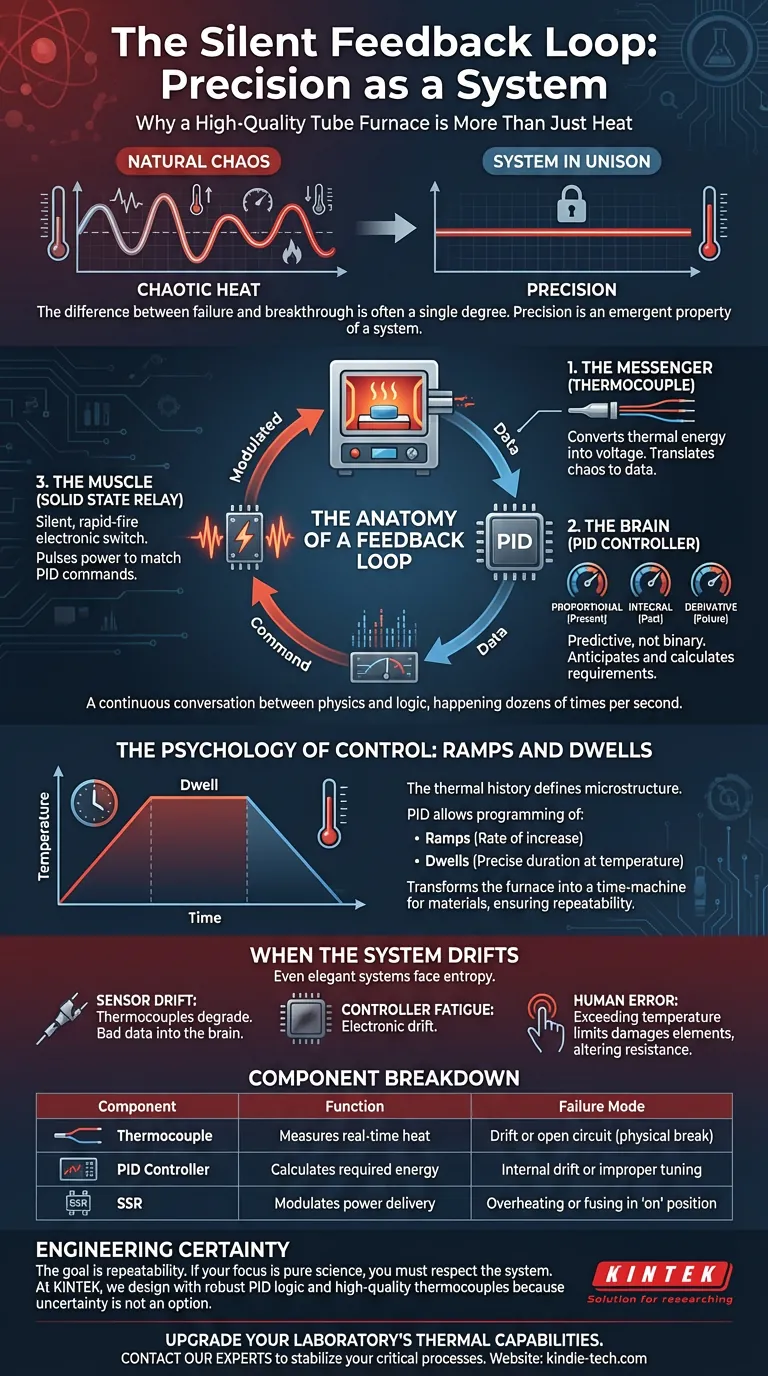

Heat is naturally chaotic. Left to its own devices, it fluctuates, overshoots, and dissipates unevenly.

In high-stakes laboratory environments—whether annealing advanced materials or growing crystals—chaos is the enemy. The difference between a failed experiment and a breakthrough often comes down to a single degree of variance.

We tend to think of a furnace as a box that gets hot. But a high-quality tube furnace is something far more complex. It is a dynamic system of checks and balances.

It is a conversation between physics and logic, happening dozens of times every second.

The Anatomy of a Feedback Loop

Accuracy does not reside in a single component. You cannot buy a "precise heater." Precision is an emergent property of a system working in unison.

In a tube furnace, this system relies on a continuous loop of information, decision, and action.

1. The Messenger (Thermocouple)

The process begins with the thermocouple. It is the nervous system of the furnace.

Composed of two dissimilar metals joined at a tip, it converts thermal energy into a tiny voltage signal. It doesn't just "feel" the heat; it translates the chaos of temperature into data.

2. The Brain (PID Controller)

The data flows to the PID (Proportional-Integral-Derivative) controller.

A standard thermostat is binary. It turns on when cold and off when hot. This creates a sawtooth pattern of temperature swings—acceptable for a home oven, but disastrous for material science.

A PID controller is predictive.

- Proportional: Looks at the present error.

- Integral: Looks at past errors (accumulation).

- Derivative: Predicts future errors based on the rate of change.

It doesn't just react; it anticipates.

3. The Muscle (Solid State Relay)

The controller sends its sophisticated command to the Solid State Relay (SSR).

Unlike mechanical relays that click and wear out, the SSR is a silent, rapid-fire electronic switch. It pulses power to the heating elements with incredible speed, modulating energy flow to match the exact requirements of the PID algorithm.

The Psychology of Control: Ramps and Dwells

Why do we need this level of complexity? Because in materials processing, the destination is less important than the journey.

The thermal history of a sample defines its microstructure.

By leveraging the PID controller, scientists can program:

- Ramps: The specific rate of temperature increase.

- Dwells: The precise duration the material sits at a specific temperature.

This transforms the furnace from a heating tool into a time-machine for materials, ensuring that every sample undergoes the exact same experience, regardless of external variables.

When the System Drifts

Even the most elegant systems are subject to entropy.

Trust is the most dangerous element in a laboratory. Assuming the number on the display matches the reality inside the tube can lead to silent failure.

When temperature instability occurs, it is rarely a mystery. It is usually a breakdown in the feedback loop:

- Sensor Drift: Thermocouples degrade over time. A damaged junction provides false data to the controller. The brain acts perfectly on bad information.

- Controller Fatigue: Electronic components can drift.

- Human Error: Pushing a furnace beyond its maximum rated temperature creates permanent damage to the heating elements, altering the resistance and throwing off the PID tuning.

The Component Breakdown

Understanding where failure points exist allows you to prevent them.

| Component | Function | Failure Mode |

|---|---|---|

| Thermocouple | Measures real-time heat | Drift or open circuit (physical break) |

| PID Controller | Calculates required energy | Internal drift or improper tuning parameters |

| SSR | Modulates power delivery | Overheating or fusing in the "on" position |

Engineering Certainty

The goal of a tube furnace is not just heat. It is repeatability.

If your focus is troubleshooting, start with the sensor. If your focus is longevity, respect the temperature limits. But if your focus is pure science, you must respect the system as a whole.

At KINTEK, we understand that our equipment is the baseline for your research. We design our tube furnaces with robust PID logic and high-quality thermocouples because we know that in your work, uncertainty is not an option.

We build the control systems so you can focus on the discovery.

Are you ready to upgrade your laboratory's thermal capabilities? Contact Our Experts to discuss how our precision equipment can stabilize your most critical processes.

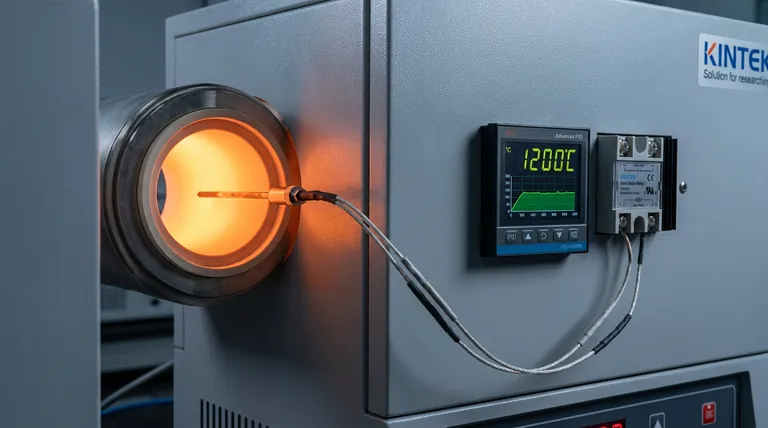

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- How Controlled Atmosphere Furnaces Improve Quality and Consistency in Heat Treatment

- The Benefits of Controlled Atmosphere Furnaces for Sintering and Annealing Processes

- Why Your Brazed Joints Keep Failing: The Invisible Saboteur in Your Furnace

- Atmosphere Furnaces: Comprehensive Guide to Controlled Heat Treatment

- Controlled Atmosphere Furnace: Comprehensive Guide to Advanced Heat Treatment