You’ve invested in a state-of-the-art high-temperature furnace for a critical project—perhaps sintering medical implants or growing a perfect crystal. You meticulously program the temperature profile, place the high-value sample inside, and initiate the cycle. Hours later, you open the chamber, only to find a disaster.

The sample is contaminated, discolored, or brittle. Even worse, you notice the furnace’s expensive tungsten heating elements—the very components that are supposed to withstand extreme heat—look corroded and fragile, as if they've aged years in a single run. What went wrong?

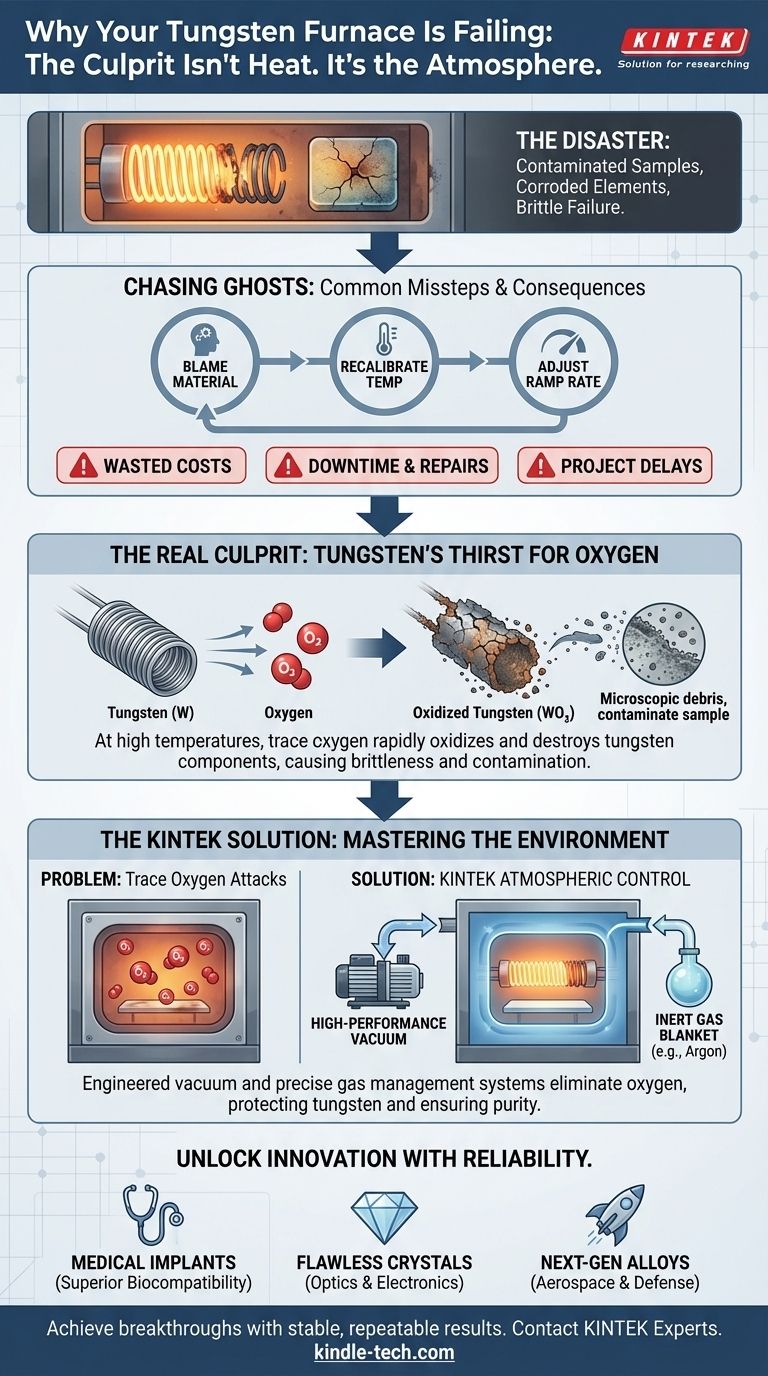

Chasing Ghosts: Why Common Fixes Only Make Things Worse

This frustrating scenario is more common than you might think. When a high-temperature process fails, the immediate instinct is to troubleshoot the most obvious variables. Laboratory teams find themselves trapped in a costly cycle of trial and error:

- Blaming the material: "Maybe there was an issue with this batch of raw powder."

- Recalibrating the temperature: "Let's re-run the cycle 10 degrees hotter and see what happens."

- Adjusting the ramp rate: "Perhaps we heated it up too quickly."

Each failed attempt doesn't just waste time. It carries significant business consequences. Each ruined sample represents wasted high-value materials. Each unexpected repair means costly downtime and service fees for replacing damaged tungsten components. Most importantly, these recurring failures lead to crippling project delays, jeopardizing product quality and putting critical contracts or research milestones at risk.

You're stuck treating symptoms, because the real disease lies hidden in plain sight.

The Real Culprit: It’s Not the Heat, It’s the Atmosphere

The reason you chose a tungsten furnace is its phenomenal resistance to heat. With a melting point of 3422°C (6192°F), it's the undisputed champion of high-temperature stability. But this incredible strength masks a critical weakness, an Achilles' heel that is the true source of your problems.

Tungsten's Hidden Weakness: A Thirst for Oxygen

At high temperatures, tungsten reacts aggressively with oxygen. Even trace amounts of air left inside the furnace chamber will cause the tungsten components to oxidize rapidly. This chemical reaction doesn't just create microscopic contaminants that ruin your sensitive samples; it physically destroys the tungsten components, making them brittle, weak, and ultimately useless.

This is why your previous attempts at a fix were doomed to fail. Adjusting the temperature or ramp rate is like trying to fix a leaky boat by painting it a different color. You're working on the wrong problem. The root cause of failure isn't the heat—it's the atmosphere the heat is applied in. Unless you can create a pristine, oxygen-free environment, your tungsten furnace will always be fighting against itself.

The Right Tool for the Real Job: Mastering the Environment

To truly leverage tungsten's power, you need more than just a hot box. You need a system meticulously designed to solve the oxidation problem. You need to control the furnace's atmosphere with absolute precision.

This is where the design philosophy behind a KINTEK high-temperature vacuum furnace becomes critical. Our furnaces are engineered not just to get hot, but to create an exceptionally clean and controlled environment where tungsten can thrive.

-

The Problem: Trace oxygen attacks tungsten and contaminates samples.

-

The KINTEK Solution: Our advanced, high-performance vacuum systems are designed to aggressively pump down the chamber, removing the air and the oxygen within it to create a deep vacuum. This starves the oxidation reaction of its fuel.

-

The Problem: Maintaining a stable, inert environment during the entire cycle is difficult.

-

The KINTEK Solution: Our precise gas management and backfilling systems allow you to displace any remaining air with an ultra-pure inert gas like argon. This provides a protective blanket, ensuring the tungsten heating elements and your product remain pristine from start to finish.

A KINTEK furnace isn't just a collection of parts; it's a purpose-built solution. It’s designed from the ground up with a deep understanding of tungsten's underlying chemistry, transforming it from a fragile material into an unstoppable workhorse.

Beyond Troubleshooting: What Will You Create with a Truly Reliable Furnace?

When you stop worrying about equipment failure and contamination, you unlock new potential. A furnace that provides a consistently pure, controlled atmosphere ceases to be a source of frustration and becomes an engine for innovation.

With this newfound reliability, you can now:

- Develop medical implants with superior biocompatibility, free from the oxide layers that compromise safety and performance.

- Grow flawless artificial crystals for the optics and electronics industries, where even the slightest carbon or oxygen contamination is unacceptable.

- Sinter next-generation alloys for aerospace and defense, pushing the boundaries of material science with confidence.

- Run complex, long-duration thermal cycles for R&D, knowing your equipment is stable and your results are repeatable.

Solving this furnace challenge is about more than just one successful run; it's about enabling your team to innovate faster, guarantee product quality, and take on more ambitious projects. If you're ready to move past the cycle of troubleshooting and start achieving breakthrough results, our team is here to help you configure the right system for your specific goals. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures

- High Pressure Tube Furnace: Applications, Safety, and Maintenance

- Installation of Tube Furnace Fitting Tee

- The Glass Ceiling: Navigating the True Thermal Limits of Quartz Tube Furnaces