Fundamentally, no. Autoclaves are not all the same, and the differences are critical to ensuring proper sterilization. While all autoclaves use pressurized steam to kill microorganisms, they differ significantly in their method of air removal, which in turn dictates the types of materials, or "loads," they can safely sterilize.

The crucial distinction between autoclaves lies in how they handle air inside the chamber. Air is an insulator that prevents steam from reaching every surface, so its effective removal is the single most important factor in a successful sterilization cycle. The type of load you need to sterilize—whether simple and solid or complex and porous—will determine the type of autoclave you require.

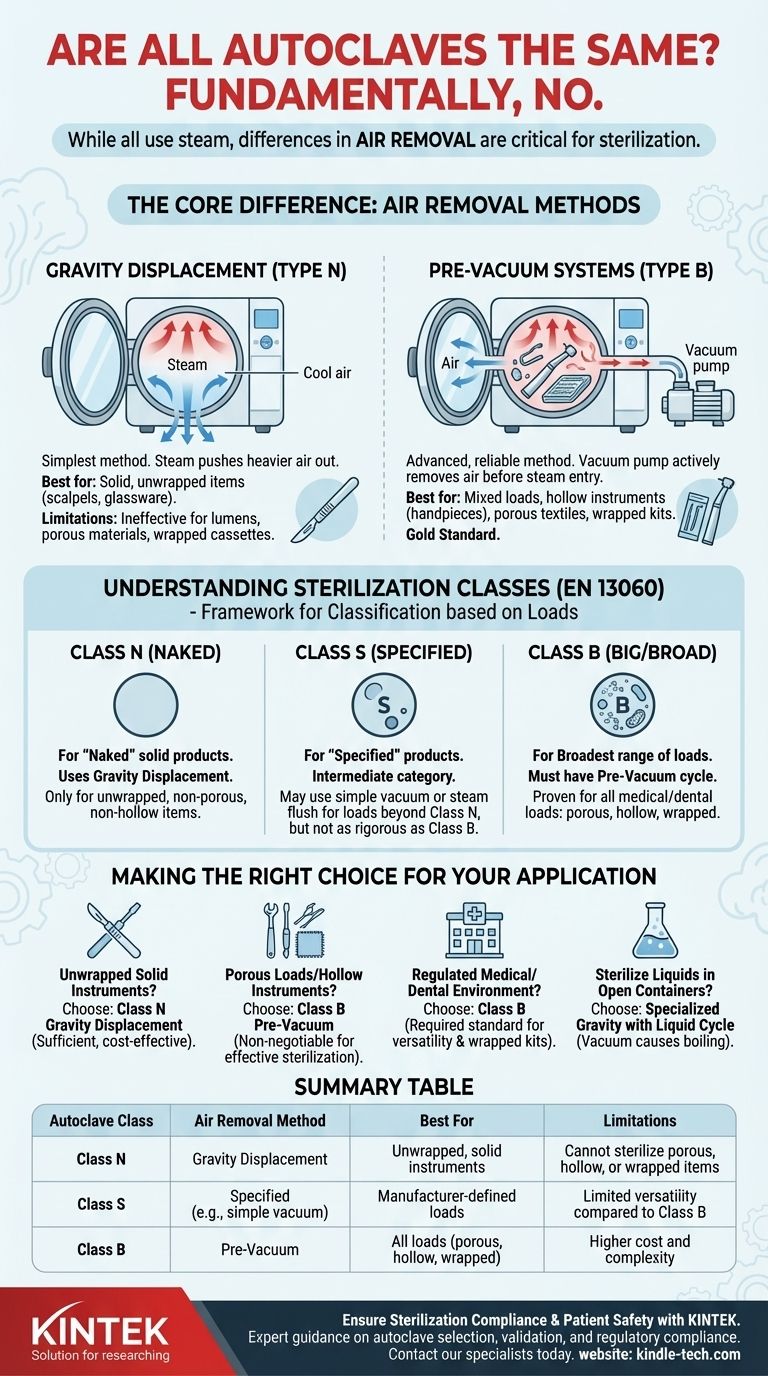

The Core Difference: Air Removal Methods

The central challenge of steam sterilization is ensuring that steam makes direct contact with 100% of an item's surface area. Trapped air pockets create cold spots where microorganisms can survive. The primary difference between autoclave types is their strategy for solving this problem.

Gravity Displacement (Type N)

This is the simplest method. Steam is generated and piped into the chamber, and because steam is less dense than cool air, it fills the chamber from the top down, pushing the heavier air out through a vent at the bottom.

These autoclaves are best suited for sterilizing simple, non-porous, and unwrapped items, such as solid scalpels or basic laboratory glassware.

However, this passive method is ineffective for items with lumens (hollow tubes), porous materials like textiles, or even wrapped instrument cassettes, as air can easily become trapped inside.

Pre-Vacuum Systems (Type B)

This is a more advanced and reliable method. Before steam is introduced, a vacuum pump actively removes the air from the chamber. This creates a negative pressure environment, ensuring that when steam is introduced, it can instantly penetrate deep into complex and porous loads.

These systems often perform multiple vacuum pulses to guarantee complete air removal from the most challenging items.

Pre-vacuum autoclaves are the gold standard for sterilizing mixed loads, including hollow instruments (like dental handpieces), porous textiles (gowns and drapes), and wrapped surgical kits.

Understanding Sterilization Classes (EN 13060)

The European standard EN 13060 provides a clear framework for classifying small steam sterilizers based on the types of loads they can process. This classification is directly tied to the air removal method.

Class N

Class N autoclaves are designed for sterilizing "Naked" solid products. They typically use the gravity displacement method for air removal.

These are the most basic type and should only be used for unwrapped, solid instruments without any hollows, crevices, or porous characteristics.

Class S

Class S autoclaves are designed for sterilizing "Specified" products as defined by the manufacturer. They represent an intermediate category.

They may have a simple, single-stage vacuum pump or use another method like steam flushing to handle specific load types beyond what a Class N can manage, but they do not meet the rigorous performance of a Class B.

Class B

Class B autoclaves are designed for the broadest range of loads. The "B" can be thought of as standing for "Big" or "Broad."

These machines must incorporate a pre-vacuum cycle and are proven to sterilize all types of loads found in medical, dental, and veterinary practices, including porous, hollow, and wrapped items. They offer the highest level of sterilization assurance.

Understanding the Trade-offs

Choosing an autoclave is not just about capability but also about balancing cost, complexity, and risk.

Cost and Complexity

Gravity displacement (Class N) autoclaves are mechanically simpler, making them less expensive to purchase and maintain.

Pre-vacuum (Class B) autoclaves are more complex due to the vacuum pump and associated controls. This results in a higher initial cost and potentially more demanding maintenance schedules.

Cycle Time and Efficiency

While a simple gravity cycle might seem faster, a full Class B cycle includes crucial pre-vacuum and post-vacuum drying phases. The active drying phase is critical for maintaining the sterility of wrapped packs.

Attempting to sterilize complex loads in a Class N unit is not just ineffective; it creates a significant risk of using a non-sterile instrument on a patient.

Load Validation and Risk

The most common pitfall is using a Class N autoclave for a load that requires a Class B cycle. This is a primary cause of sterilization failure.

Regardless of the autoclave type, the process must be validated. Using chemical and biological indicators is essential to confirm that your specific loads are being successfully sterilized in your machine.

Making the Right Choice for Your Application

Your decision must be driven by the most challenging items you need to sterilize, not the most common ones.

- If your primary focus is simple, unwrapped solid instruments: A Class N gravity displacement autoclave is a sufficient and cost-effective choice.

- If your primary focus is porous loads (gowns, textiles) or hollow instruments (dental handpieces, endoscopes): A Class B pre-vacuum autoclave is non-negotiable to ensure effective sterilization.

- If you operate in a regulated medical or dental environment: A Class B autoclave is almost always the required standard due to its versatility and ability to handle complex, wrapped instrument cassettes.

- If you need to sterilize liquids in open containers: A specialized gravity autoclave with a liquid cycle is required, as a vacuum would cause the liquids to boil over.

Understanding these core differences empowers you to select not just a machine, but the correct sterilization process for guaranteed safety and compliance.

Summary Table:

| Autoclave Class | Air Removal Method | Best For | Limitations |

|---|---|---|---|

| Class N | Gravity Displacement | Unwrapped, solid instruments | Cannot sterilize porous, hollow, or wrapped items |

| Class S | Specified (e.g., simple vacuum) | Manufacturer-defined loads | Limited versatility compared to Class B |

| Class B | Pre-Vacuum | All loads (porous, hollow, wrapped) | Higher cost and complexity |

Ensure Sterilization Compliance and Patient Safety with KINTEK

Choosing the wrong autoclave can lead to sterilization failures and compliance risks. KINTEK specializes in laboratory equipment and consumables, offering a range of autoclaves tailored to your specific needs—from basic Class N units for simple instruments to advanced Class B systems for complex loads.

Our experts will help you:

- Select the right autoclave class for your application

- Validate your sterilization processes

- Ensure regulatory compliance

Don't compromise on safety. Contact our sterilization specialists today for a personalized consultation and ensure your lab operates with the highest standards of sterility and efficiency.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How often do autoclaves need to be cleaned? A Guide to Protecting Your Lab's Sterilization Integrity

- What are the maintenance procedures for autoclave? Ensure Sterilization Safety and Reliability

- What factors may result in sterilization failure when using an autoclave? Prevent Failed Cycles with Expert Tips

- What role does a high-pressure autoclave play in the synthesis of porous HA? Master Precision Hydrothermal Synthesis

- Are there any specific types of contamination that an autoclave cannot remove? Understanding the Limits of Steam

- How does a slow strain rate testing system integrated with an autoclave facilitate material research? | KINTEK

- How do you clean an autoclave in a lab? Ensure Sterilization Efficacy & Extend Equipment Life

- Why is autoclaving so vital? The Definitive Guide to Steam Sterilization