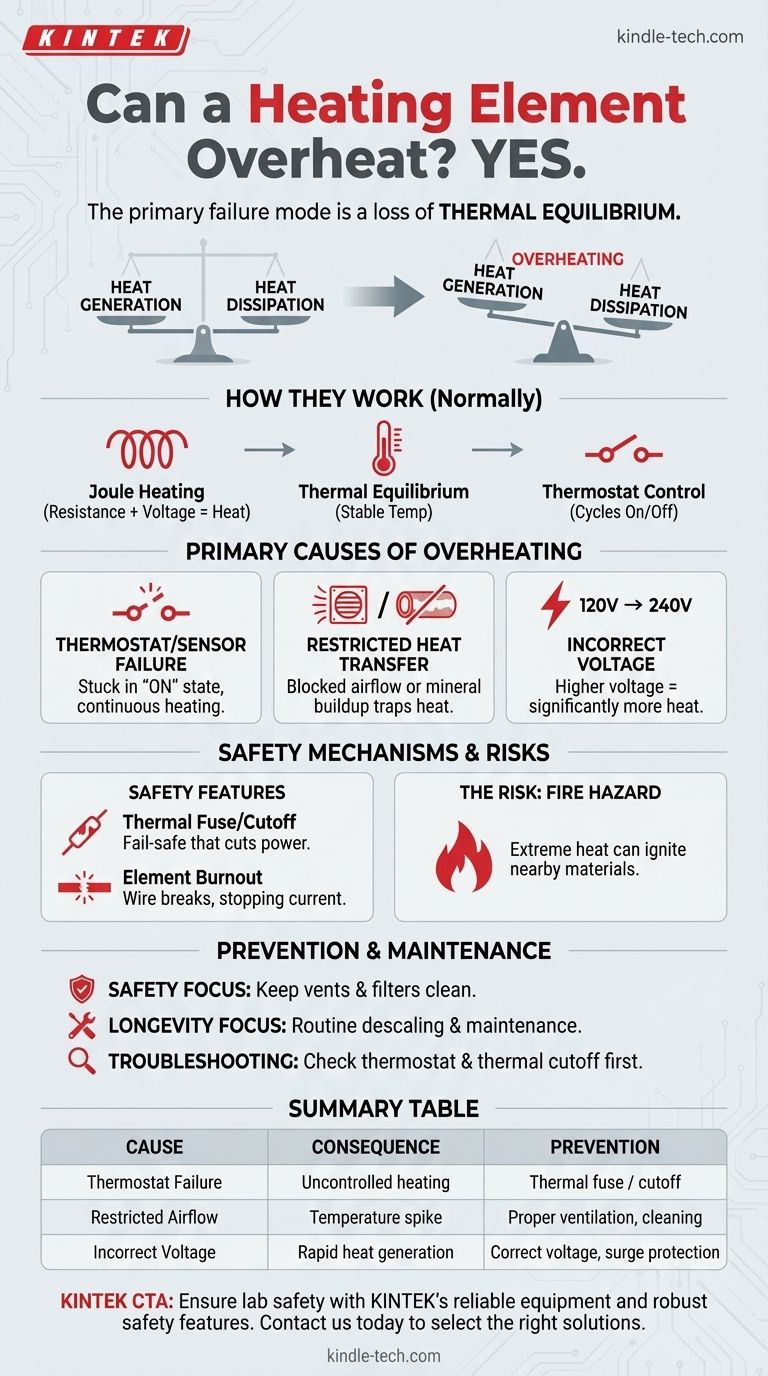

Yes, a heating element can absolutely overheat. In fact, overheating is the primary failure mode for many heating elements and the appliances they are in. This occurs when the element reaches a temperature that exceeds its design limits, leading to damage to the element itself, its surrounding components, or even creating a fire hazard.

The core issue is a loss of thermal equilibrium. A heating element is designed to operate at a stable temperature where the heat it generates is safely transferred away. Overheating happens when this balance is broken—either because the element is generating too much heat or, more commonly, because it can't get rid of the heat it's producing.

How Heating Elements Work (And Why They Don't Normally Overheat)

To understand why overheating happens, you first need to understand how an element is designed to function safely.

The Principle of Resistive Heating

Heating elements work through a principle called Joule heating. When electrical current flows through a material with high resistance, like a Nichrome (nickel-chromium) alloy wire, the electrical energy is converted directly into heat.

The amount of heat produced is determined by the element's resistance and the voltage applied.

Reaching Thermal Equilibrium

An element doesn't get infinitely hot. As it heats up, it begins to radiate that heat to its environment (air in a space heater, water in a kettle).

Eventually, it reaches a point of thermal equilibrium, where the rate of heat generation is perfectly matched by the rate of heat dissipation. The element is specifically designed to operate safely at this equilibrium temperature for long periods.

The Role of Thermostats and Controllers

Most appliances don't run their heating elements continuously. They use thermostats, temperature sensors, and control circuits to maintain a desired temperature.

The controller cycles the element on and off to keep the temperature within a narrow range, preventing it from running unchecked and exceeding its safe operating limit.

The Primary Causes of Overheating

Overheating is a failure state. It happens when one of the systems designed to maintain thermal equilibrium breaks down.

Thermostat or Sensor Failure

This is the most common culprit. If the thermostat or temperature sensor fails, it may no longer signal the controller to shut off the power.

The element, stuck in the "on" state, continues to generate heat indefinitely. It will quickly surpass its designed equilibrium temperature and enter an overheating state.

Restricted Airflow or Heat Transfer

An element can only dissipate heat if there is a medium to transfer it to. If this pathway is blocked, the heat becomes trapped.

For example, a space heater's vent being covered by a blanket prevents cool air from flowing over the element. In a water heater, a thick layer of mineral scale can insulate the element from the water. In both cases, the element's temperature will spike dramatically, even if it's producing a normal amount of heat.

Incorrect Voltage or Power Surges

Heating elements are designed for a specific voltage. The power (and thus heat output) is proportional to the square of the voltage.

Applying a higher-than-specified voltage—for instance, using an appliance designed for 120V on a 240V circuit—will cause it to generate far more heat than it was designed for, leading to rapid failure.

Understanding the Safety Mechanisms

Because overheating is a known risk, appliances include multiple layers of protection.

Thermal Fuses and Cutoffs

This is the most critical safety feature. A thermal fuse or thermal cutoff is a one-time-use device designed to be the last line of defense.

If the primary thermostat fails and the temperature rises to a dangerous level, this fuse will melt or break, permanently opening the electrical circuit and cutting power to the element. It is a fail-safe designed to prevent a fire.

Material Limitations and Burnout

The element wire itself provides a final, albeit destructive, safety mechanism. As Nichrome wire gets extremely hot, it oxidizes very quickly.

This makes the wire brittle, and it will eventually break, interrupting the flow of electricity. This "burnout" is a failure of the element, but it safely stops the uncontrolled heating process.

The Inherent Risk of Fire

The ultimate consequence of a catastrophic overheating failure is fire. If all safety systems fail and the element's temperature continues to rise, it can easily reach the ignition point of nearby materials like plastic, dust, or wood.

How to Apply This to Your Appliance

Understanding why overheating occurs allows you to use and maintain your devices more effectively.

- If your primary focus is safety: Never obstruct the vents on a heater, and regularly clean lint filters in dryers. These actions ensure the element can always dissipate its heat.

- If your primary focus is appliance longevity: Perform routine maintenance, such as descaling your water heater, to prevent buildup that insulates the element and forces it to run hotter.

- If you are troubleshooting an appliance: If a device either won't heat or gets dangerously hot, the thermostat and thermal cutoff are the first components to inspect, as their failure is a direct cause of heating problems.

By recognizing that heating elements exist in a delicate balance, you can ensure they operate safely and last for their intended lifespan.

Summary Table:

| Cause of Overheating | Primary Consequence | Key Prevention/Safety Feature |

|---|---|---|

| Thermostat/Sensor Failure | Uncontrolled heating, element damage | Thermal fuse / cutoff (fail-safe) |

| Restricted Airflow/Heat Transfer | Temperature spike, component stress | Proper ventilation, routine cleaning |

| Incorrect Voltage / Power Surge | Rapid heat generation, element burnout | Using correct voltage, surge protection |

Ensure your laboratory equipment operates safely and efficiently. Uncontrolled heating can damage sensitive experiments and create safety risks. KINTEK specializes in reliable lab equipment and consumables, designed with robust safety features for precise temperature control. Our experts can help you select the right heating solutions for your specific laboratory needs.

Contact us today via our contact form to discuss how we can support your lab's safety and performance.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What role do laboratory heaters and thermocouples play in low-temperature nitriding? Achieve Precision Thermal Control

- How do integrated Pt100 temperature sensors assist in the study of dissolution kinetics of materials in liquid tin?

- Do heating elements lose power over time? The science behind inevitable performance decline

- How long should a heating element last? Maximize your oven's lifespan with these key insights.

- What temperature can graphite handle? Unlocking its extreme heat resistance in inert environments

- What is the suitability of tungsten as an electrical conducting material for heating applications? Master Extreme High-Temperature Heating

- What is the advantage of a quartz heater? Get Instant, Targeted Warmth for Maximum Efficiency

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab