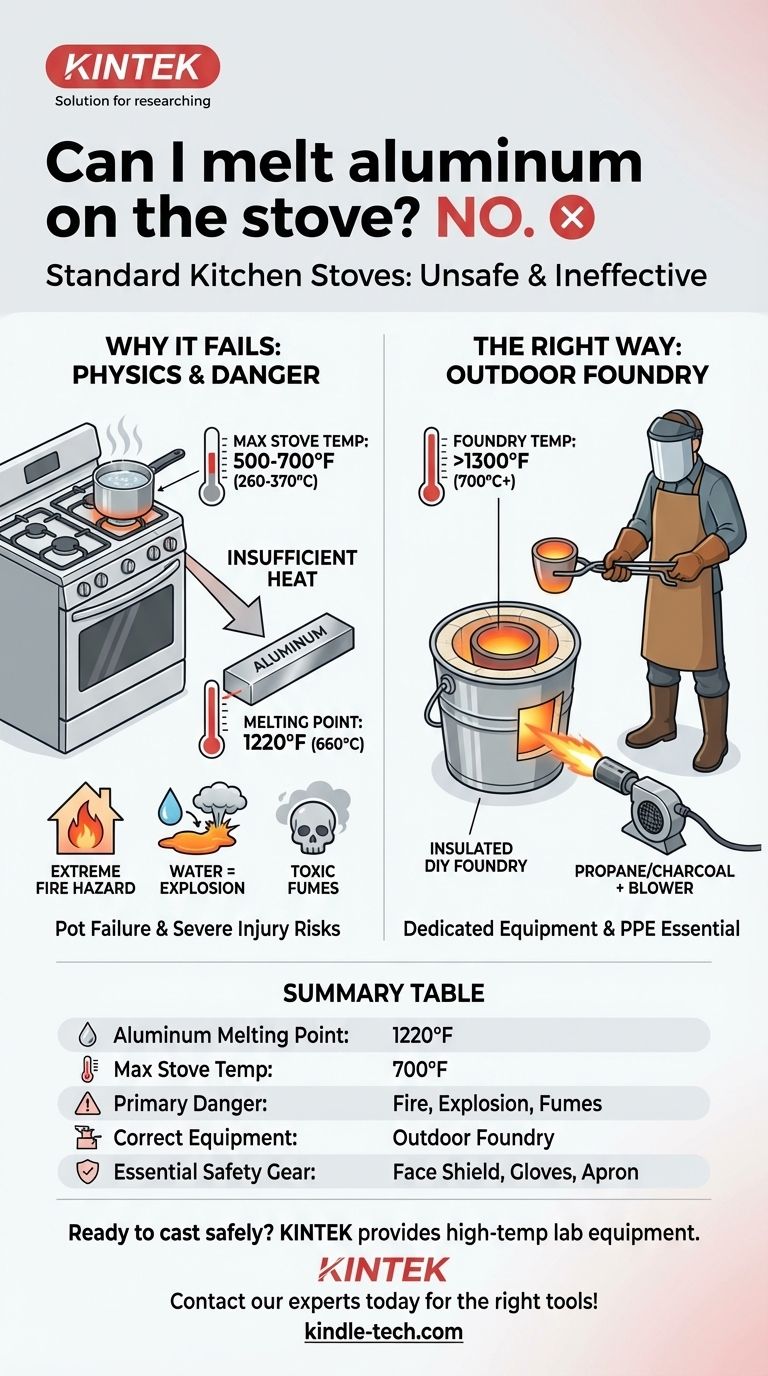

No, you cannot safely or effectively melt aluminum on a standard kitchen stove. While it seems like a simple task, a home stove fails to meet the fundamental temperature requirements for melting metal and creates an extremely hazardous environment for the attempt.

The core issue is twofold: a kitchen stove simply cannot produce the sustained, high temperature of 1220°F (660°C) needed to melt aluminum, and trying to do so introduces unacceptable risks of fire, toxic fumes, and severe injury.

Why Your Kitchen Stove Falls Short

Attempting to melt aluminum on a stove is not a matter of patience; it's a matter of physics. The equipment is fundamentally mismatched for the task.

The Critical Temperature Barrier

The melting point of aluminum is approximately 1220°F or 660°C. This is a fixed physical property.

A standard kitchen stove, whether gas or electric, is designed for cooking, which happens at much lower temperatures.

Maximum Stove Temperatures

An electric coil or glass-top stove may reach temperatures of 500-700°F (260-370°C). A gas flame is hotter at its source, but the heat that actually transfers into a pot is regulated for cooking, not metallurgy.

In short, no part of your stove's normal operation is designed to reach and sustain the temperature needed to turn solid aluminum into a liquid.

The Problem of Heat Transfer

Even if a small part of a gas flame could technically reach the required temperature, the stove isn't designed to transfer that heat effectively into a block of metal.

A stove heats the bottom of a pan. A proper furnace or foundry is designed to envelop the metal in heat from all sides, ensuring a uniform and efficient melt.

The Unacceptable Dangers of Trying

Beyond the simple fact that it won't work, attempting to melt aluminum in a kitchen is incredibly dangerous. The environment is entirely wrong for handling molten metal.

Extreme Fire Hazard

Your kitchen is full of flammable materials, from cooking oils and grease residue to wooden cabinets and paper towels. Bringing an open heat source to its absolute maximum for an extended period creates a significant and uncontrolled fire risk.

Molten Metal and Water Don't Mix

Kitchens are water-rich environments. If even a single drop of water comes into contact with molten aluminum, it will flash into steam instantaneously and expand over 1,500 times its original volume.

This causes a violent explosion that can spray molten metal over a wide area, leading to catastrophic fires and life-threatening burns.

Toxic Fume Inhalation

Most aluminum you might want to melt, like soda cans or scrap, is not pure. It is coated with paints, plastics, and other chemicals.

Heating these materials releases toxic and carcinogenic fumes. Your kitchen's vent hood is not equipped to handle this type of chemical exhaust, exposing you and your family to hazardous air.

Catastrophic Equipment Failure

A kitchen pot is not a crucible. A crucible is a ceramic or metal container specifically designed to withstand extreme thermal stress and contain molten metal.

A steel or aluminum pot will likely fail, either by melting itself or by cracking from the intense, focused heat, spilling molten metal and starting a fire.

The Right Tools for the Job

Melting metal is an accessible hobby, but it requires dedicated equipment and a commitment to safety. This means moving the operation out of the kitchen and into a well-ventilated outdoor space.

Building a DIY Foundry

For a few dollars, you can build a small, effective foundry capable of melting aluminum. These are often called "bucket" or "coffee can" forges.

The key components are a steel container, a refractory lining (often a mix of plaster of Paris and sand) to hold the heat, and a lid.

A Powerful Heat Source

Your foundry will need a fuel source far more potent than a stovetop. The two most common choices for beginners are charcoal or propane.

This fuel is combined with forced air from a blower (often a hairdryer) to dramatically increase the temperature inside the foundry, easily surpassing aluminum's melting point.

Essential Safety Gear (PPE)

Working with molten metal requires Personal Protective Equipment (PPE). This is not optional.

At a minimum, you need a full-face shield, heavy leather welding gloves, a leather apron, and closed-toed boots (preferably leather). Synthetic clothing can melt to your skin and should never be worn.

Getting Started with Metal Casting Safely

Understanding the correct approach is the first step toward a rewarding and safe hobby.

- If your primary focus is curiosity: Understand that melting aluminum is a task for dedicated tools, and a kitchen stove is fundamentally unsafe and unsuited for the job.

- If your primary focus is starting a new hobby: Your first step should be researching DIY foundry designs and acquiring the necessary PPE before you ever handle any metal.

- If your primary focus is a specific project: Prioritize building a safe, outdoor setup. The time spent creating a proper foundry is a small investment to prevent a fire or serious injury.

Approaching metalworking with respect for the heat and a focus on safety is the key to turning an idea into reality.

Summary Table:

| Key Point | Detail |

|---|---|

| Aluminum Melting Point | 1220°F (660°C) |

| Max Stove Temperature | ~500-700°F (260-370°C) |

| Primary Danger | Fire, toxic fumes, steam explosions |

| Correct Equipment | Outdoor foundry with propane/charcoal |

| Essential Safety Gear | Face shield, leather gloves, apron |

Ready to start your metal casting project safely and effectively?

Don't risk your safety with inadequate equipment. KINTEK specializes in high-temperature lab and workshop equipment, including crucibles and safety gear designed for metallurgy. Our products help hobbyists and professionals achieve precise, controlled melts without the dangers of a kitchen setup.

Contact our experts today to find the right tools for your needs and cast with confidence!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the brazing process in short note? Master the Key Parameters for Strong Metal Joints

- How does a laboratory vacuum oven facilitate the activation of Porous Aromatic Frameworks (PAFs)? Unlock Active Sites

- What role do high-precision melting furnaces play in stir casting? Master Precision in Zinc-Based Composites

- What is the function of a high-temperature calcination furnace in the phase transformation of CoxAl3FeyOm±δ catalysts?

- What is sintering in hydrogen? Achieve Superior Purity and Strength in Metal Parts

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity

- What is the density of sintered material? A Design Choice for Performance, Not a Fixed Number

- What type of furnace is used for metal casting? Choose the Right Furnace for Your Process