Ultimately, the design of a tube furnace is dictated entirely by its intended application. The core factors that shape its construction are the required process temperature, the necessary atmospheric conditions, the characteristics of the material being processed, desired throughput, and any specific cooling requirements.

A tube furnace is not a generic piece of equipment; it is a purpose-built system. Every design choice, from the tube material to the physical layout, is a direct response to the specific demands of the scientific or industrial process it must perform.

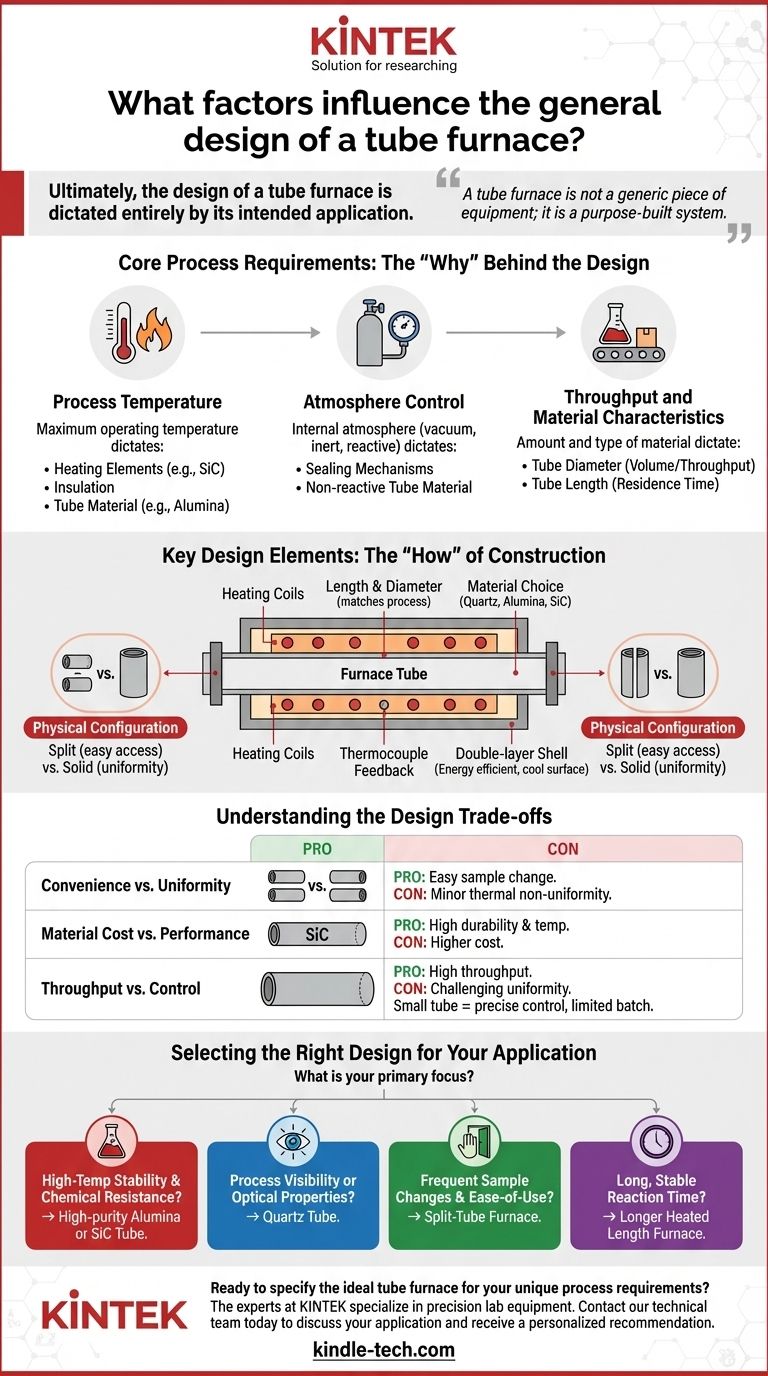

Core Process Requirements: The "Why" Behind the Design

Before any physical components are chosen, the fundamental parameters of the process must be defined. These requirements are the primary drivers of the furnace's final form and function.

Process Temperature

The maximum operating temperature is the most critical factor. It directly determines the selection of heating elements, insulation materials, and the furnace tube itself.

Different materials have different temperature limits. For example, a process requiring extremely high temperatures will necessitate heating elements like silicon carbide (SiC) and a robust tube material like alumina.

Atmosphere Control

The furnace's internal atmosphere is crucial for many processes. The design must accommodate the need for a vacuum, an inert gas like argon, or a specific reactive gas environment.

This requirement influences the sealing mechanisms at the ends of the tube and the choice of tube material, which must be non-reactive with the process gases at high temperatures.

Throughput and Material Characteristics

The amount and type of material to be processed dictate the physical dimensions of the furnace tube.

A larger diameter tube accommodates a higher throughput, or volume of material. The tube's length influences the residence time—how long the material is exposed to heat—which is critical for ensuring complete chemical reactions or material transformations.

Key Design Elements: The "How" of Construction

Based on the core process requirements, engineers make specific choices about the furnace's physical components and overall structure.

The Furnace Tube

The tube is the heart of the system. Its length, diameter, and material are chosen to match the process.

A longer tube provides a longer residence time, while a shorter tube can increase gas velocity and improve mixing.

Material choice is a key trade-off. Quartz is common for its high-temperature tolerance and optical transparency, but it is brittle. For more robust or higher-temperature applications, materials like alumina or silicon carbide are used.

Heating and Insulation

A standard tube furnace uses a cylindrical cavity surrounded by heating coils. These coils are embedded in a thermally insulating matrix to direct heat inward efficiently and safely.

Temperature is precisely regulated using feedback from a thermocouple. Modern designs often feature a double-layer shell structure, which helps create a balanced temperature field, keeps the outer surface cool, and conserves energy.

Physical Configuration

Furnaces come in two primary configurations: solid and split. A split tube furnace is divided into two halves that can be opened.

This design allows for easy loading and unloading of samples or reactors without disturbing the entire setup, making it ideal for applications requiring frequent access.

Understanding the Design Trade-offs

Selecting a tube furnace involves balancing competing priorities. There is no single "best" design, only the most appropriate one for a specific task.

Convenience vs. Uniformity

A split tube furnace offers superior convenience for sample changes. However, the seam between the two halves can sometimes introduce a minor point of thermal non-uniformity compared to a solid, single-piece furnace chamber.

Material Cost vs. Performance

High-performance tube materials like silicon carbide offer exceptional durability and temperature resistance. This performance comes at a higher cost compared to more common materials like alumina or quartz.

Throughput vs. Control

A wider and longer tube increases throughput but can make it more challenging to achieve a perfectly uniform temperature zone across its entire length. A smaller tube offers more precise thermal control but limits the batch size.

Selecting the Right Design for Your Application

Your choice should be guided by the single most important aspect of your work.

- If your primary focus is high-temperature stability and chemical resistance: Prioritize a furnace with a high-purity alumina or silicon carbide tube.

- If your primary focus is process visibility or specific optical properties (e.g., crystal growth): A furnace designed around a quartz tube is the correct choice.

- If your primary focus is frequent sample changes and operational ease-of-use: A split-tube furnace will provide the most significant workflow advantage.

- If your primary focus is achieving a long, stable reaction time: Select a furnace with a longer heated length to maximize the material's residence time.

Ultimately, a clear understanding of your process goals will lead you directly to the optimal furnace design.

Summary Table:

| Key Design Factor | Impact on Furnace Design |

|---|---|

| Process Temperature | Determines heating element type, insulation, and tube material (e.g., quartz, alumina, SiC). |

| Atmosphere Control | Influences sealing mechanisms and tube material to handle vacuum, inert, or reactive gases. |

| Material Throughput | Dictates tube diameter and length for batch size and required residence time. |

| Application Need | Drives configuration choice (e.g., split-tube for easy access vs. solid for thermal uniformity). |

Ready to specify the ideal tube furnace for your unique process requirements?

The experts at KINTEK specialize in designing and supplying precision lab equipment, including tube furnaces tailored for specific temperatures, atmospheres, and throughput. We help you navigate the trade-offs to ensure optimal performance and efficiency.

Contact our technical team today to discuss your application and receive a personalized recommendation.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How is a laboratory tube heating furnace configured for high-temperature failure studies? Master Reactor Precision

- How does a multi-heating zone horizontal tube furnace benefit alloy testing? Maximize Thermal Uniformity and Throughput

- How does a tube furnace contribute to the final sintering process of LATP solid-state electrolyte green pellets?

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- Why are high-strength Pressure Tubes used for seaweed hydrolysis? Unlock Efficient Biomass Degradation

- What is the high temperature of a tube furnace? Unlock the Right Model for Your Application

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What specific conditions does a tubular furnace provide for the reduction of Pt catalysts? Optimize Your Catalyst Performance