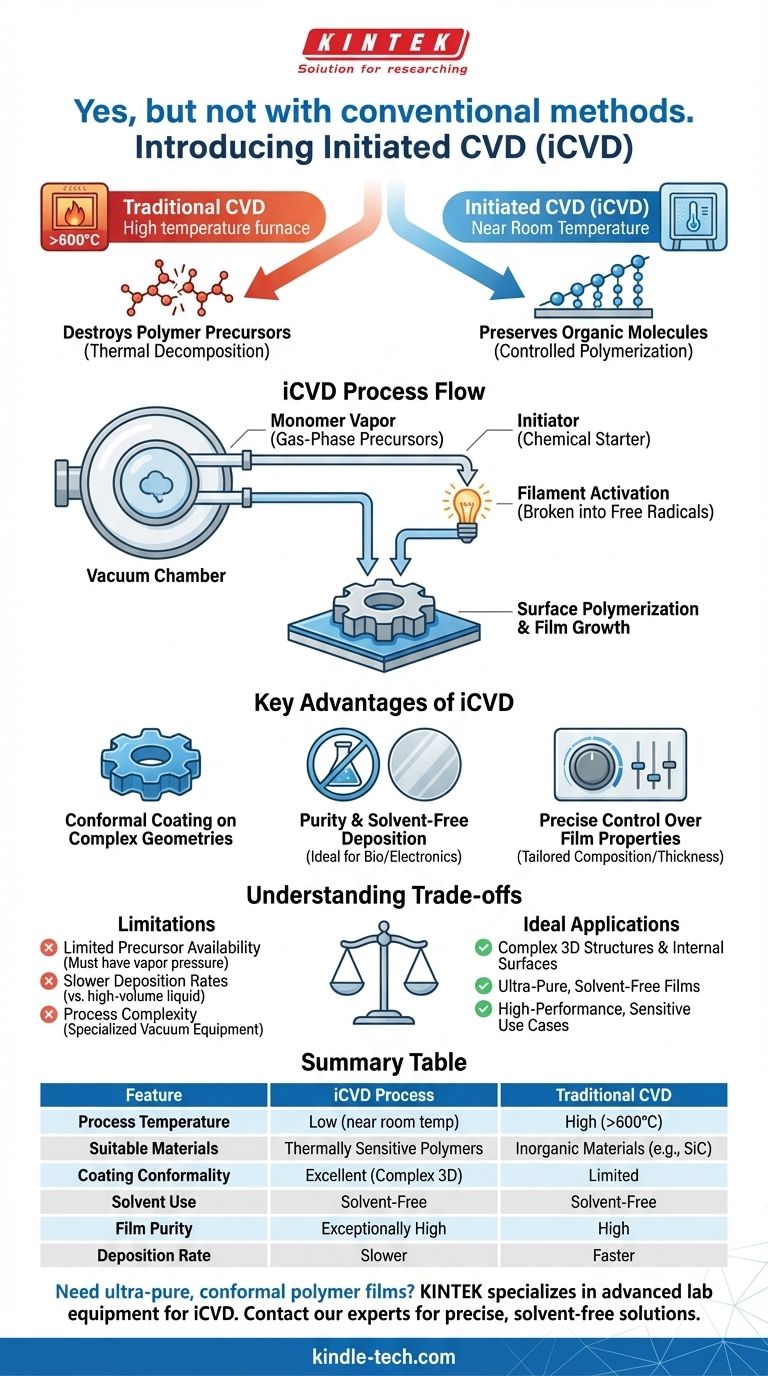

Yes, but not with conventional methods. While traditional Chemical Vapor Deposition (CVD) is designed for high-temperature inorganic materials, polymers are deposited using a specialized, low-temperature variant of the process. This method allows for the creation of high-purity, ultra-thin polymer films without damaging the delicate organic molecules.

The core challenge is that conventional CVD operates at temperatures that would destroy polymer precursors. The solution is a process called initiated Chemical Vapor Deposition (iCVD), a solvent-free technique that enables precise control over polymer film growth on a wide variety of surfaces.

How Polymer CVD Differs from Traditional Methods

Traditional CVD, used for materials like silicon carbide or zinc sulfide, relies on high temperatures (often >600°C) to break down precursor gases and deposit a film. This approach is fundamentally incompatible with organic polymer chemistry.

The Challenge with Polymer Precursors

Most organic molecules, or monomers, that form polymers are thermally sensitive. Exposing them to the extreme heat of a conventional CVD reactor would cause them to decompose uncontrollably rather than polymerize in a controlled fashion.

Introducing Initiated CVD (iCVD)

The iCVD process circumvents the need for high heat. It introduces monomer gases into a vacuum chamber along with a separate initiator chemical. This initiator, not high temperature, is the key to starting the polymerization reaction.

The Role of the Initiator

The initiator is gently heated over a filament, causing it to break apart into highly reactive free radicals. These radicals then react with the monomer molecules at the surface of the substrate, "initiating" the chain-growth reaction that forms the polymer film, all at near room temperature.

Key Advantages of the iCVD Process

By avoiding high temperatures and liquid solvents, the iCVD process offers unique benefits for creating advanced functional surfaces and coatings.

Conformal Coating on Complex Geometries

Because the process uses gas-phase precursors in a vacuum, iCVD can deposit a perfectly uniform and conformal polymer film over highly complex, three-dimensional structures. This is extremely difficult to achieve with liquid-based methods like spin-coating.

Purity and Solvent-Free Deposition

The entire process is solvent-free, eliminating the risk of residual solvents being trapped in the final film. This results in exceptionally pure polymer coatings, which is critical for applications in biomedical devices and high-performance electronics.

Precise Control Over Film Properties

Like other vacuum deposition techniques, iCVD provides unmatched control over material properties. By precisely managing the flow rates of different monomers and the initiator, it is possible to engineer films with tailored composition, thickness, and functionality.

Understanding the Trade-offs

While powerful, the iCVD process has specific limitations that make it suitable for some applications more than others. Understanding these trade-offs is crucial for making an informed decision.

Limited Precursor Availability

The process requires monomers that have sufficient vapor pressure to be introduced into the vacuum chamber as a gas. This excludes many common polymers whose building blocks are solids with low volatility.

Slower Deposition Rates

Compared to some high-volume liquid-phase coating methods, iCVD can have a lower deposition rate. This can make it less cost-effective for applications requiring very thick films or extremely high throughput.

Process Complexity

Operating a vacuum deposition system requires specialized equipment and expertise. The initial capital investment and operational know-how for iCVD are more significant than for simpler methods like dip-coating.

Making the Right Choice for Your Application

Selecting the right deposition method depends entirely on your end goal. The unique characteristics of iCVD make it ideal for specific, high-performance use cases.

- If your primary focus is coating complex 3D structures or internal surfaces: iCVD is a superior choice due to its ability to create truly conformal films.

- If your primary focus is creating ultra-pure, solvent-free films for sensitive applications: iCVD is one of the best methods available for biomedical or electronic-grade polymer coatings.

- If your primary focus is high-volume production of simple, thick films: You may find that traditional liquid-phase processing is more economical and efficient.

Ultimately, iCVD provides a powerful tool for engineering advanced polymer surfaces with a level of precision that is simply not possible with conventional techniques.

Summary Table:

| Feature | iCVD Process | Traditional CVD |

|---|---|---|

| Process Temperature | Low (near room temperature) | High (>600°C) |

| Suitable Materials | Thermally sensitive polymers | Inorganic materials (e.g., silicon carbide) |

| Coating Conformality | Excellent for complex 3D structures | Limited |

| Solvent Use | Solvent-free | Solvent-free |

| Film Purity | Exceptionally high | High |

| Deposition Rate | Slower | Faster |

Need to deposit ultra-pure, conformal polymer films on complex components? KINTEK specializes in advanced lab equipment, including solutions for specialized processes like initiated CVD (iCVD). Our expertise helps you achieve precise, solvent-free coatings for sensitive applications in biomedical devices and electronics. Contact our experts today to discuss how we can support your specific laboratory needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- How many types of sputtering are there? A Guide to DC, RF, and Advanced Techniques