In practice, PVD coating is not applied directly to raw wood. While Physical Vapor Deposition (PVD) is a highly versatile process compatible with metals, ceramics, and many plastics, wood's natural properties—porosity, moisture content, and low heat tolerance—make it fundamentally incompatible with the standard PVD process. Achieving a PVD finish on a wood product requires a specialized multi-step preparation to first transform its surface into a suitable substrate.

The core challenge is not the PVD process itself, but the wood's inherent characteristics. To successfully apply PVD, the wood must first be completely sealed to create a non-porous, vacuum-stable surface, effectively making it behave like plastic or metal.

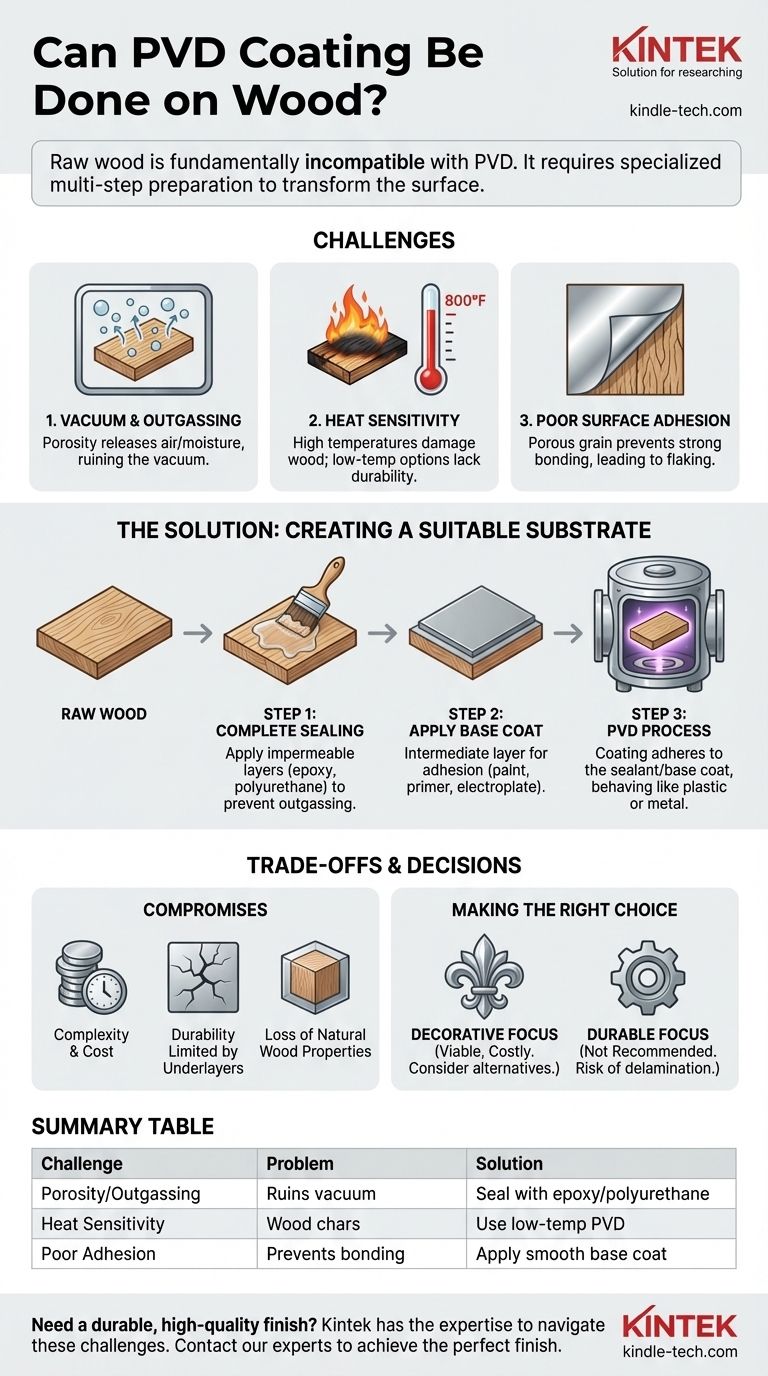

Why Direct PVD Coating on Wood is Problematic

PVD creates a thin film by vaporizing a solid material in a vacuum and depositing it onto a target substrate. The nature of wood presents three primary obstacles to this process.

The Vacuum Chamber Environment

PVD requires a high-vacuum environment to allow vaporized particles to travel freely. Wood is porous and naturally contains trapped air and moisture. When placed in a vacuum, this trapped material will escape in a process called outgassing, which destabilizes the vacuum, contaminates the chamber, and prevents a uniform, high-quality coating from forming.

Substrate Temperature Sensitivity

Many industrial PVD processes operate at elevated temperatures to ensure strong adhesion and a durable coating. Some processes require heating the substrate to over 800°F (425°C). Wood cannot withstand these temperatures and would be severely damaged or even combust long before the coating process is complete. While some low-temperature PVD methods exist, they may not offer the same durability.

Poor Surface Adhesion

PVD films require a clean, smooth, and non-porous surface to achieve optimal adhesion. The natural grain and cellular structure of raw wood provide a poor foundation for the microscopic layer of a PVD coating, leading to weak bonding and a high likelihood of flaking or peeling.

The Solution: Creating a Suitable Substrate

The key to applying a PVD finish to a wood object is to first modify its surface so it no longer behaves like wood. This involves encasing it in a material that is compatible with the PVD process.

Step 1: Complete Sealing

The first and most critical step is to completely seal the wood's surface. This is typically done by applying multiple thick coats of a non-porous material like a high-solids epoxy, polyurethane, or specialized lacquer. The goal is to create an impermeable barrier that prevents any outgassing from the wood when placed under vacuum.

Step 2: Applying a Base Coat

After the wood is perfectly sealed and smooth, an intermediate base coat is often applied. This layer serves as the ideal foundation for the PVD coating to adhere to. For decorative applications, this might be a layer of paint or primer. For more robust applications, the sealed part might be electroplated with a metal like nickel or chrome, as PVD adheres exceptionally well to these surfaces.

Step 3: The PVD Process

Only after the wood is fully sealed and prepared with a suitable base coat can it be placed in a PVD chamber. At this point, the process is no different from coating a plastic part. The PVD material adheres to the sealant or base coat, not the wood itself.

Understanding the Trade-offs

While technically possible through preparation, this method comes with significant compromises that are crucial to understand.

Complexity and Cost

This multi-step process is significantly more labor-intensive and expensive than applying PVD to a compatible material like stainless steel. The cost of sealing, sanding, and applying base coats can easily exceed the cost of the PVD process itself.

Durability is Limited by the Underlayers

The final product's durability is not just a function of the hard PVD coating. Its weak point is the adhesion of the initial sealant layer to the wood. Any impact that damages this underlying bond will cause the entire coating system—sealant, base coat, and PVD—to fail and delaminate.

Loss of Natural Wood Properties

This method completely encases the wood. The final product will look and feel like metal or coated plastic, not wood. While a transparent sealant might preserve the visual appearance of the wood grain underneath, the tactile warmth and character of the wood are lost.

Making the Right Choice for Your Application

Before pursuing this complex process, clarify your ultimate goal.

- If your primary focus is a decorative metallic finish: PVD on sealed wood is a viable but costly option. You should also evaluate alternatives like high-quality metallic paints, foils, or gilding, which may achieve a similar aesthetic with less complexity.

- If your primary focus is a highly durable, wear-resistant surface: This method is generally not recommended. The risk of delamination from the wood substrate is high. A better engineering solution is to use a PVD-coated metal component or apply a wood veneer onto a metal substrate that can be reliably coated.

Ultimately, successfully applying PVD to wood is a matter of transforming its surface, balancing the desired high-tech finish with the practical limits of the underlying organic material.

Summary Table:

| Challenge | Why It's a Problem for PVD | Solution |

|---|---|---|

| Porosity & Outgassing | Trapped air/moisture ruins the vacuum. | Seal wood with epoxy or polyurethane. |

| Heat Sensitivity | Wood chars at high PVD temperatures. | Use low-temperature PVD processes. |

| Poor Adhesion | Rough, porous surface prevents bonding. | Apply a smooth, non-porous base coat. |

Need a durable, high-quality finish for your product?

While PVD coating wood is complex, KINTEK has the expertise and equipment to help you navigate the challenges. Whether your project requires specialized surface preparation or you're exploring alternative materials, our team can provide a solution tailored to your laboratory or manufacturing needs.

Contact our experts today to discuss how we can help you achieve the perfect finish for your application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition