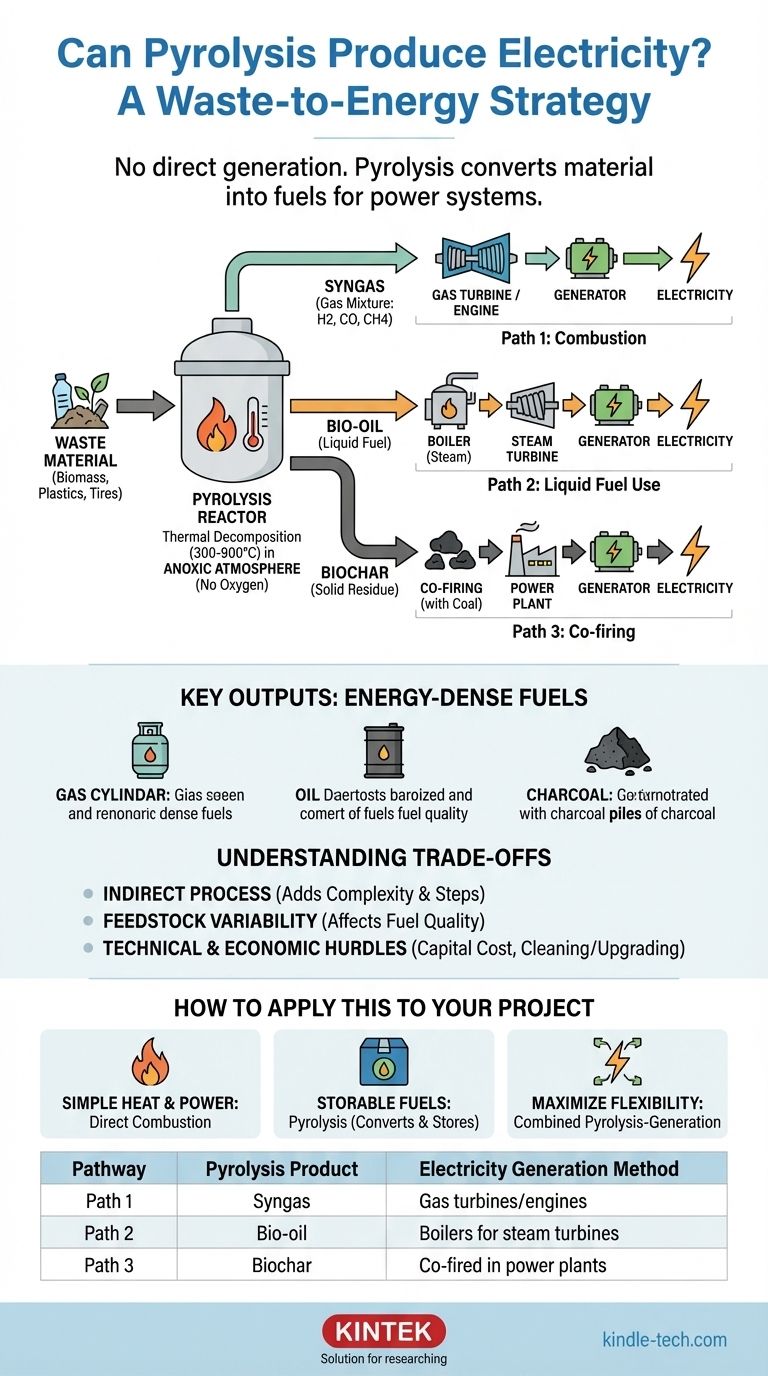

In short, pyrolysis does not directly produce electricity. It is a thermal process, not an electrochemical one like a battery. However, pyrolysis is a critical intermediate step in a powerful waste-to-energy strategy, as it converts organic materials into energy-dense fuels that can then be used to generate electricity through conventional methods.

The core distinction is that pyrolysis is a material conversion process, not a power generation process. It excels at transforming complex waste into stable, transportable fuels (gas, liquid, and solid), which then feed separate systems designed to produce electricity.

What is Pyrolysis and What Does It Produce?

To understand how pyrolysis enables electricity generation, you must first understand what it is and what it creates. It is fundamentally a pre-treatment or conversion technology.

Defining the Process

Pyrolysis is the thermal decomposition of materials at elevated temperatures (typically 300–900°C) in an anoxic atmosphere, meaning an environment with little to no oxygen.

This lack of oxygen is the key difference between pyrolysis and incineration (combustion). Instead of burning the material and releasing its energy as heat all at once, pyrolysis breaks it down into a new set of valuable chemical products.

The Key Outputs: Energy-Dense Fuels

The process breaks down complex organic matter (like biomass, plastics, or tires) into three primary, energy-rich products:

- Syngas: A combustible gas mixture containing hydrogen, carbon monoxide, carbon dioxide, and methane. This can be used as a fuel gas.

- Bio-oil (Pyrolysis Oil): A dark, viscous liquid that is essentially a type of crude oil. It is energy-dense and can be stored and transported.

- Biochar: A stable, solid residue rich in carbon, similar to charcoal. This solid fuel retains a significant portion of the original material's energy.

The Pathways from Pyrolysis to Electricity

Once pyrolysis has converted waste into these three fuel types, each can be used to generate electricity through established technologies. The pyrolysis unit itself does not have electrodes or produce a current; it acts as a fuel factory.

Path 1: Combustion of Syngas

The syngas produced during pyrolysis can be piped directly from the reactor and burned. It is most commonly used to fuel gas turbines or internal combustion engines, which are connected to a generator to produce electricity. This is one of the most efficient and direct pathways.

Path 2: Using Bio-oil as a Liquid Fuel

Bio-oil can be used much like conventional fuel oil. It can be burned in a boiler to produce high-pressure steam, which then expands through a steam turbine connected to an electrical generator. It can also be used in certain large, low-speed diesel engines for power generation.

Path 3: Co-firing with Biochar

Biochar is a solid fuel that can be burned. A common application is co-firing, where it is mixed with traditional fuels like coal and burned in the boiler of a conventional thermal power plant. This displaces a portion of the fossil fuel, reducing net carbon emissions.

Understanding the Trade-offs

While the pyrolysis-to-electricity pathway is effective, it is essential to recognize its complexities and challenges. It is not a simple, one-step solution.

Indirect Process Adds Complexity

The multi-step nature of the process (Feedstock -> Pyrolysis -> Fuel -> Combustion -> Electricity) introduces more equipment and control points than direct incineration. Each conversion step has potential for energy loss, reducing overall net efficiency if not engineered correctly.

Feedstock and Output Variability

The exact ratio and chemical quality of syngas, bio-oil, and biochar depend heavily on the type of feedstock and the pyrolysis conditions (temperature, heating rate). Inconsistent waste streams can lead to variable fuel quality, which can complicate the stable operation of downstream generators.

Technical and Economic Hurdles

Pyrolysis systems require significant capital investment. Furthermore, the raw syngas and bio-oil often require cleaning or upgrading before they can be used in engines or turbines to prevent corrosion and fouling. These additional processing steps add cost and complexity to the overall system.

How to Apply This to Your Project

Choosing a waste-to-energy technology depends entirely on your primary goal. Pyrolysis offers unique advantages over direct combustion, but it is not always the best fit.

- If your primary focus is simple, large-scale heat and power generation: Direct combustion (incineration) in a mass-burn facility may be a more straightforward, albeit less flexible, solution.

- If your primary focus is creating valuable, storable fuels from waste: Pyrolysis is an excellent choice, as it converts inconsistent waste into stable gas, liquid, and solid energy carriers that can be stored, transported, or sold.

- If your primary focus is maximizing resource recovery and flexibility: A combined pyrolysis-generation system is ideal. It allows you to transform waste into multiple fuel types that can be used on-demand to generate electricity or for other applications.

Ultimately, pyrolysis serves as a powerful bridge, transforming challenging waste streams into valuable fuels for more flexible and often cleaner energy production.

Summary Table:

| Pathway | Pyrolysis Product | Electricity Generation Method |

|---|---|---|

| Path 1 | Syngas | Combusted in gas turbines or engines |

| Path 2 | Bio-oil | Burned in boilers for steam turbines |

| Path 3 | Biochar | Co-fired with coal in power plants |

Ready to transform your waste into energy? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Our solutions help laboratories optimize waste-to-energy processes, from feedstock analysis to fuel characterization. Whether you're developing new pyrolysis technologies or scaling up existing systems, we provide the reliable equipment and expertise you need. Contact us today to discuss how we can support your sustainable energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is sputtering rate? Master the Key to Controlling Thin Film Deposition Speed

- What is the purpose of using a cooling water system after wheat straw pretreatment? Optimize Sugar Yield and Safety

- How does a high-precision oven contribute to the post-processing of hydrothermal oxidation products? Ensure Data Purity

- What are the limitations of melting point determination? Understand Purity, Technique, and Material Behavior

- Why is a thin film circuit important? Achieve Unmatched Precision for High-Frequency Electronics

- Why is an additional annealing process required following silicification? Ensure Composite Stability & Durability

- How is an electron beam evaporator cooled during deposition? Essential Thermal Management for Stable Processes

- What is pull down time in ULT freezers and what factors affect it? Ensure Your Sample Security with Efficient Cooling