In short, yes, you can absolutely heat treat a metal part more than once. It is a common and necessary procedure in metallurgy for correcting errors, altering a part's function, or restoring properties after fabrication processes like welding. However, each heat cycle is a significant event in the metal's life and must be approached with a clear understanding of the material and the goal.

Re-heat treating isn't about simply repeating a step; it's a deliberate process of first erasing the metal's previous structural state and then creating a new one. Success hinges on a precise understanding of the material's history, as each cycle introduces risks like distortion and material degradation.

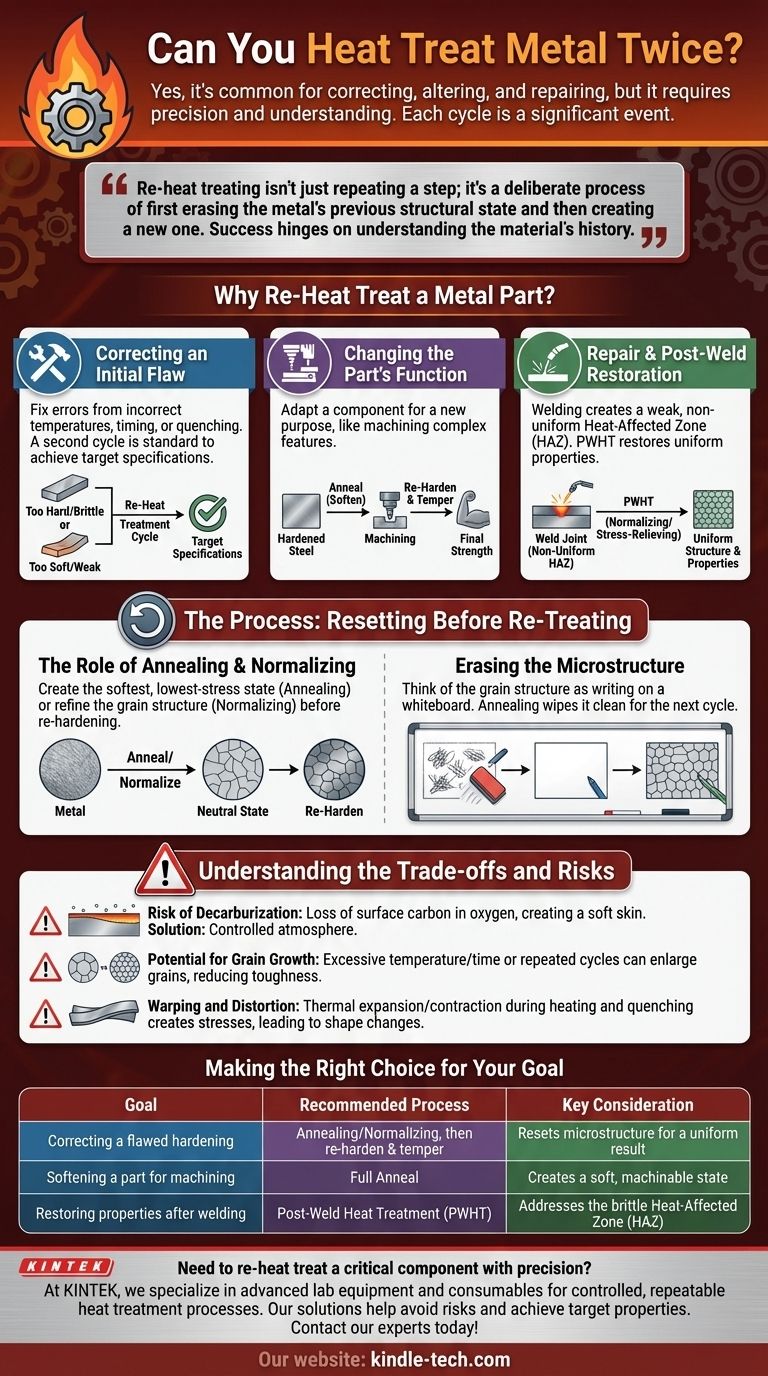

Why Re-Heat Treat a Metal Part?

Re-heat treatment is not an afterthought but a planned metallurgical process driven by specific needs. It’s a powerful tool for rectifying issues or adapting a component for a new purpose.

Correcting an Initial Flaw

A part may come out of its first heat treatment too hard and brittle, or too soft and weak. This can be due to incorrect temperatures, timing, or quenching methods. A second heat treatment cycle is the standard way to correct this and achieve the target specifications.

Changing the Part's Function

Imagine you have a hardened steel block that now needs complex features machined into it. In its hard state, it would be extremely difficult and costly to machine. The solution is to anneal it (a type of heat treatment) to make it soft, perform the machining, and then re-harden and temper it to its final required strength.

Repair and Post-Weld Restoration

Welding introduces intense, localized heat that dramatically alters the metal's microstructure in the heat-affected zone (HAZ) around the weld. This area becomes a patchwork of different properties—some brittle, some soft—creating a major weak point. A post-weld heat treatment (PWHT) cycle, such as normalizing or stress-relieving, is often required to refine the grain structure and restore uniform mechanical properties across the entire part.

The Process: Resetting Before Re-Treating

You cannot simply "add" more hardness or "top up" a previous heat treatment. To get a predictable and uniform result, you must first reset the metal's internal crystal structure to a neutral, predictable state.

The Role of Annealing and Normalizing

Before re-hardening a part, you must almost always perform a preliminary cycle like annealing or normalizing. Annealing heats the metal and cools it very slowly, creating the softest, lowest-stress state possible. Normalizing uses a slightly faster air-cooling process that also erases prior hardening effects and refines the grain structure.

Erasing the Microstructure

Think of the metal's internal grain structure as writing on a whiteboard. The first heat treatment is the initial message. To write something new, you don't just write over the old text; you must wipe the board clean. Annealing is the act of wiping the board clean, creating a uniform blank slate for the next hardening and tempering cycle.

Understanding the Trade-offs and Risks

While re-heat treating is effective, it is not without risks. Each thermal cycle is an opportunity for things to go wrong.

Risk of Decarburization

For carbon steels, heating the material in the presence of oxygen can cause carbon to diffuse out of the surface. This decarburization leaves a soft, low-carbon skin on the part, which will not harden properly. This risk increases with each heat cycle and can be mitigated by using a controlled, oxygen-free furnace atmosphere.

Potential for Grain Growth

Holding a metal at high temperatures for too long or cycling it repeatedly can cause its internal crystals (grains) to grow larger. Excessive grain growth can significantly reduce the metal's toughness and make it more prone to fracture. Precise temperature and time control is critical to prevent this.

Warping and Distortion

Every time a part is heated and rapidly cooled (quenched), it undergoes thermal expansion and contraction, creating internal stresses. Each cycle is another opportunity for these stresses to cause the part to warp, twist, or distort, especially in components with complex geometries or thin sections.

Making the Right Choice for Your Goal

Your approach to re-heat treatment should be dictated entirely by your objective. There is no one-size-fits-all process.

- If your primary focus is correcting a flawed hardening: Your first step must be a full annealing or normalizing cycle to reset the material before attempting the hardening and tempering process again.

- If your primary focus is modifying a part for machining: A full anneal is the correct process to soften the metal, followed by a complete re-hardening and tempering cycle after machining is complete.

- If your primary focus is repairing a welded part: A post-weld heat treatment (PWHT), often involving normalizing or stress-relieving, is essential to restore uniform mechanical properties across the part and the weld zone.

Understanding heat treatment as a repeatable, deliberate process transforms it from a final step into a versatile tool for achieving precise material properties.

Summary Table:

| Goal | Recommended Process | Key Consideration |

|---|---|---|

| Correcting a flawed hardening | Annealing/Normalizing, then re-harden & temper | Resets microstructure for a uniform result |

| Softening a part for machining | Full Anneal | Creates a soft, machinable state |

| Restoring properties after welding | Post-Weld Heat Treatment (PWHT) | Addresses the brittle Heat-Affected Zone (HAZ) |

Need to re-heat treat a critical component with precision?

At KINTEK, we specialize in the advanced lab equipment and consumables necessary for controlled, repeatable heat treatment processes. Our expertise helps you avoid risks like decarburization and distortion, ensuring your metal parts achieve their target properties—whether for correction, adaptation, or repair. Let our solutions support your laboratory's success.

Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision