Yes, hardening fundamentally affects a material's dimensions. Nearly all hardening processes involve thermal cycles and internal structural changes that cause parts to grow, shrink, warp, or otherwise distort. This dimensional variation is not a defect but an inherent consequence of the metallurgical transformations that increase hardness and strength.

The core challenge in precision manufacturing is not if dimensions will change during hardening, but how to predict and control these changes. The final size and shape of a hardened part are a result of a complex interplay between thermal contraction and the volume change from internal phase transformations.

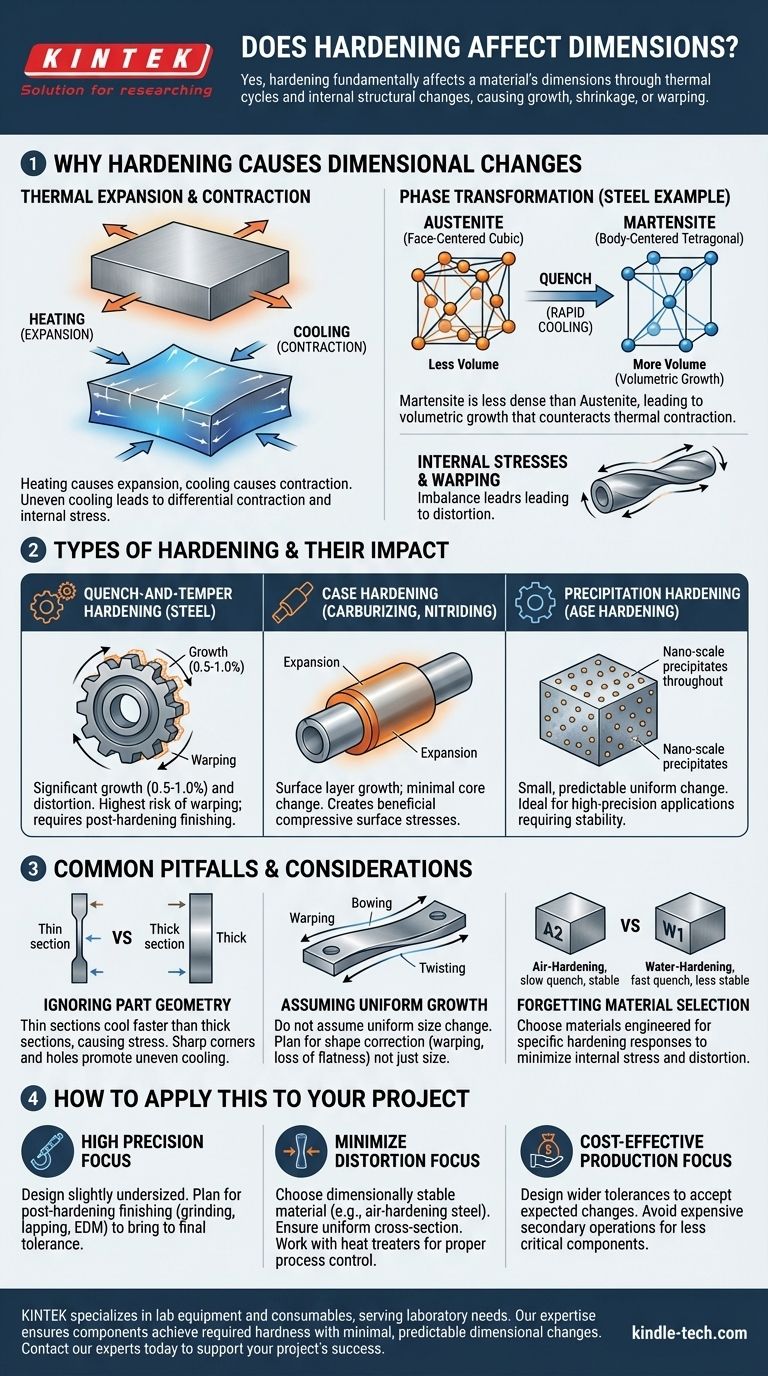

Why Hardening Causes Dimensional Changes

Understanding the sources of this change is critical for anyone designing or manufacturing high-tolerance components. The effects are driven by two primary physical phenomena.

The Role of Thermal Expansion and Contraction

This is the most straightforward factor. When you heat a metal part for hardening, it expands. When you quench or cool it, it contracts. If the cooling is not perfectly uniform across the entire part, this differential contraction alone can cause warping and internal stress.

The Critical Factor: Phase Transformation

For many materials, especially steel, hardening involves changing the material's internal crystal structure, or phase. During the heating process for steel, its structure changes to a phase called austenite.

When the steel is rapidly cooled (quenched), this austenite transforms into a very hard, brittle structure called martensite. Critically, the martensite crystal structure is less dense and takes up more physical volume than the austenite it replaces.

This volumetric growth from the martensitic transformation directly counteracts the thermal contraction from cooling, making the final dimensional change complex and difficult to predict.

Internal Stresses and Warping

The combination of rapid cooling and phase transformation rarely happens uniformly. The surface of a part cools much faster than its core, meaning the surface transforms and contracts at a different rate than the interior.

This imbalance creates immense internal stresses. These stresses relieve themselves by physically distorting the part, leading to warping, bowing, or twisting.

Types of Hardening and Their Impact

Different hardening processes create different degrees of dimensional change.

Quench-and-Temper Hardening (Steel)

This is the most common method for through-hardening steel and typically produces the most significant dimensional changes. The transformation to martensite causes a predictable volume increase, often in the range of 0.5% to 1.0%, but the final shape is highly susceptible to distortion.

Case Hardening (Carburizing, Nitriding)

These processes harden only the surface of a part. Because the phase transformation and compositional changes are confined to a thin outer "case," the dimensional growth is also concentrated there. This can cause the part's surface to grow, creating compressive stress that is often beneficial for fatigue life but must be accounted for in final dimensions.

Precipitation Hardening (Age Hardening)

This method, mentioned for aluminum and PH steels, does not rely on a martensitic transformation. Instead, it involves heating the material to lock specific elements in solution, followed by a lower-temperature aging process that allows these elements to form nano-scale precipitates.

This process causes much smaller and more predictable dimensional changes, typically a slight, uniform contraction or expansion. It is a key reason these materials are often chosen for high-precision applications where post-hardening stability is paramount.

Common Pitfalls and Considerations

Successfully managing heat treatment requires anticipating these challenges.

Ignoring Part Geometry

Dimensional change is never uniform across a complex part. Thin sections cool faster and transform sooner than thick, heavy sections. Holes, keyways, and sharp corners all create stress concentrations and promote uneven cooling, making them prime locations for cracking and distortion.

Assuming Uniform Growth

Do not assume a part will simply get bigger or smaller uniformly. Warping and loss of flatness or roundness are far more common outcomes. You must plan for shape correction, not just size correction.

Forgetting Material Selection

Different alloys are engineered for different hardening responses. An oil-hardening or air-hardening tool steel (like A2) is designed to be quenched less severely than a water-hardening steel (like W1). This slower, gentler quench significantly reduces internal stress and distortion, making the material more dimensionally stable.

How to Apply This to Your Project

Treat hardening not as a final step, but as an integral part of the manufacturing process that must be planned for from the beginning.

- If your primary focus is high precision: You must design the part with the expectation of post-hardening finishing. The standard practice is to machine the part slightly undersized, harden it, and then use grinding, lapping, or EDM to remove distortion and bring it to final tolerance.

- If your primary focus is minimizing distortion: Choose a material known for dimensional stability (like an air-hardening steel), ensure the part has a uniform cross-section where possible, and work with a heat treater who can control the process with proper fixturing and quench control.

- If your primary focus is cost-effective production: For less critical components, you may be able to design tolerances that are wide enough to accept the expected dimensional changes without requiring expensive secondary operations.

Accounting for dimensional change during hardening is a fundamental principle of engineering design and manufacturing.

Summary Table:

| Hardening Process | Primary Dimensional Effect | Key Consideration |

|---|---|---|

| Quench-and-Temper | Significant growth (0.5-1.0%) and distortion | Highest risk of warping; requires post-hardening finishing |

| Case Hardening | Surface layer growth; minimal core change | Creates beneficial compressive surface stresses |

| Precipitation Hardening | Small, predictable uniform change | Ideal for high-precision applications requiring stability |

Need precision parts that meet exact specifications after hardening? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise in material science and process optimization ensures your components achieve the required hardness with minimal, predictable dimensional changes. Contact our experts today to discuss how we can support your project's success.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the primary function of a high vacuum furnace in heat treating stainless steel? Precision Microstructural Control

- What role does a precision laboratory oven play in the hydrothermal synthesis of copper sulfate nanocrystals?

- What is the temperature of the heat of the arc in arc welding? Mastering Extreme Heat for Perfect Welds

- What are two advantages of putting sinter into the furnace? Achieve Purity and Superior Strength

- What is a pit furnace? The Vertical Solution for Large, Heavy Parts

- What role does a vacuum diffusion welding furnace play in the fabrication of multi-layer titanium alloy laminates?

- What is the purpose of the vacuum in a heat exchanger? Prevent Damage or Enable Critical Processes

- What are arc furnaces mainly used for? Efficiently Recycling Scrap into High-Quality Steel