Yes, but not through heating alone. The process that makes steel stronger is called heat treatment, which involves a highly controlled cycle of heating and cooling. Simply heating steel without a specific cooling method can actually make it softer, while the correct process fundamentally rearranges its internal structure to create a much stronger material.

The strength of steel is not determined by heat, but by how its internal crystal structure is manipulated. Heat treatment uses precise heating to unlock this structure, but it is the controlled rate of cooling that locks in the desired properties like hardness, strength, and toughness.

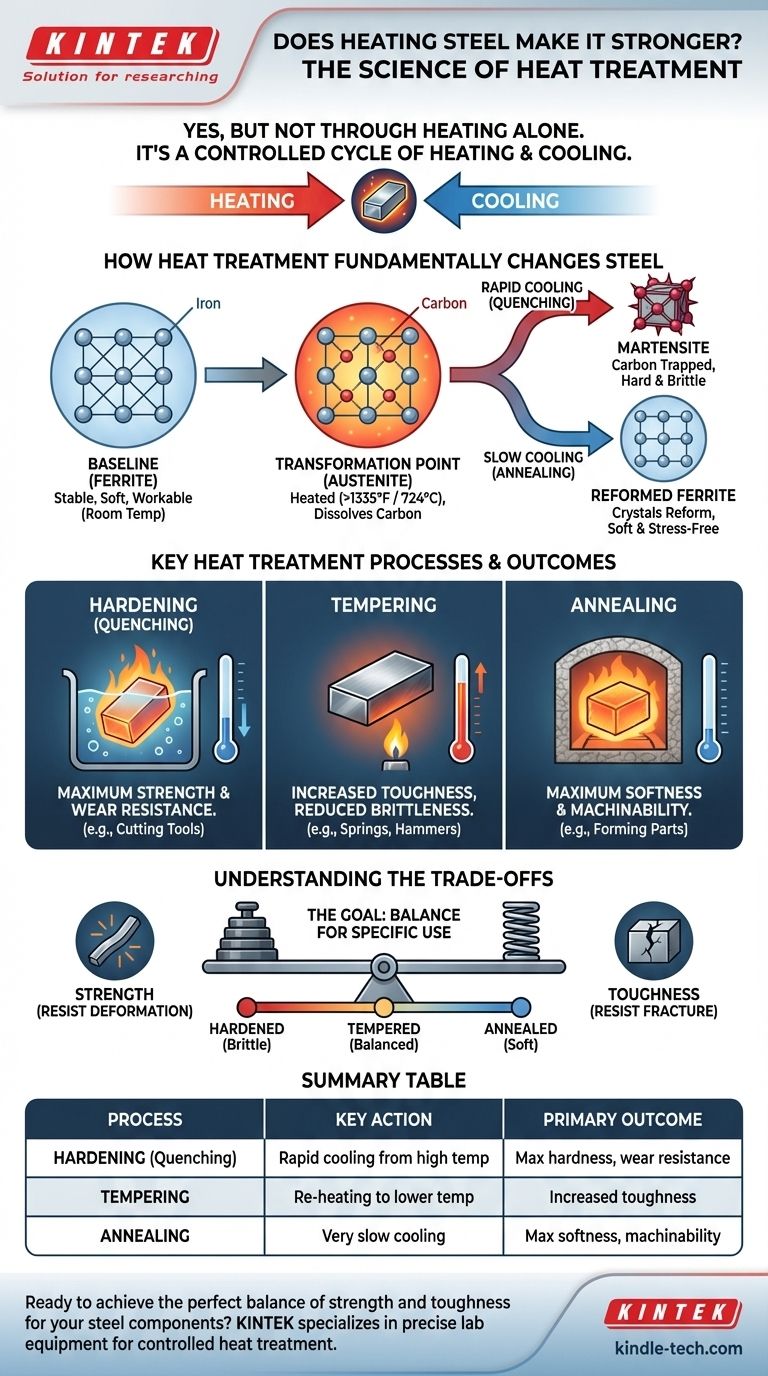

How Heat Treatment Fundamentally Changes Steel

To understand why this works, you have to think of steel not as a solid, uniform material, but as a crystalline structure. Heat treatment is the process of changing that structure.

The Baseline Crystal Structure

At room temperature, steel exists in a stable, relatively soft crystal structure known as ferrite. This structure is what makes a standard piece of steel workable and machinable.

Reaching the Transformation Point

When you heat steel above a critical temperature (typically above 1335°F or 724°C), a remarkable change occurs. The crystal structure rearranges itself into a form called austenite. The key feature of austenite is its ability to dissolve carbon, which is already present within the steel alloy.

The Critical Role of Cooling

The "magic" of heat treatment happens during the cooling phase. The speed at which you cool the steel from its austenitic state determines its final properties. The dissolved carbon gets trapped, forcing the crystals into new, powerful configurations.

Key Heat Treatment Processes and Their Outcomes

Different cooling rates produce vastly different results. This is not a one-size-fits-all process; it's tailored to achieve a specific goal.

Hardening for Maximum Strength

To make steel as hard as possible, it is cooled extremely rapidly from the austenitic state. This process is called quenching, often done by plunging the hot steel into water, oil, or brine.

This rapid cooling traps the carbon atoms, preventing them from forming the soft ferrite structure again. Instead, they form a new, highly strained, and very hard crystal structure called martensite. This is what gives a knife its edge or a bearing its wear resistance.

Tempering for Toughness

Steel that has been hardened through quenching is incredibly strong but also very brittle, like glass. For most applications, this is a dangerous liability, as a sharp impact could cause it to shatter.

Tempering is a secondary treatment where the hardened steel is re-heated to a much lower temperature. This process relieves the internal stress of the martensite structure, sacrificing some hardness to gain a significant amount of toughness (resistance to fracture).

Annealing for Softness

Conversely, if the goal is to make steel as soft and workable as possible, the opposite cooling method is used. Annealing involves cooling the steel very slowly from the austenitic state.

This slow cooling gives the crystal structures time to reform into their softest, most stable state. This process is used to relieve stress, improve machinability, and prepare the metal for further shaping or forming.

Understanding the Trade-offs

The properties of steel exist on a spectrum. You cannot maximize one without impacting another. This is the central challenge of metallurgy.

Strength vs. Toughness

These two terms are often used interchangeably, but they are technically opposites.

- Strength is the ability to resist deformation and bending.

- Toughness is the ability to resist fracture and absorb impact.

A fully hardened piece of steel has maximum strength but minimum toughness. An annealed piece has maximum toughness but minimum strength. The goal of tempering is to find the ideal balance between them for a specific application.

The Risk of Incorrect Treatment

Heat treatment is a precise science. Heating the steel to the wrong temperature, for too short or too long a time, or cooling it at the wrong rate can have negative consequences.

Overheating can ruin the grain structure permanently, while improper cooling can lead to cracks, warping, or simply failing to achieve the desired properties.

Matching the Treatment to Your Goal

The right heat treatment is entirely dependent on the intended use of the steel component.

- If your primary focus is maximum hardness and wear resistance (e.g., a file, cutting tool edge): The key process is hardening (quenching) to create a martensitic structure.

- If your primary focus is durability and impact resistance (e.g., a hammer, axe, or spring): The goal is a balance, achieved through hardening followed by tempering to add toughness.

- If your primary focus is machinability and forming (e.g., preparing a part to be shaped): The correct process is annealing to make the steel as soft and stress-free as possible.

Ultimately, heat treatment gives us the power to transform a single steel alloy into a wide range of materials, each perfectly suited for its specific task.

Summary Table:

| Heat Treatment Process | Key Action | Primary Outcome |

|---|---|---|

| Hardening (Quenching) | Rapid cooling from high temperature | Maximum hardness and wear resistance |

| Tempering | Re-heating hardened steel to a lower temperature | Increased toughness, reduced brittleness |

| Annealing | Very slow cooling from high temperature | Maximum softness and machinability |

Ready to achieve the perfect balance of strength and toughness for your steel components?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for controlled heat treatment processes. Whether you are developing cutting tools, durable springs, or complex machined parts, our solutions help you achieve the exact material properties your application demands.

Contact our experts today to discuss how we can support your laboratory's metallurgy and materials testing needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- How are high-performance vacuum furnaces used in helium implantation annealing? Master Material Defect Visualization

- How does sintering affect mechanical properties? Master the Key to Stronger, Denser Materials

- What critical role does a halogen infrared heating furnace play in converting TiO2 to TiN? Optimize Your RTN Process

- What role does a high-precision tempering furnace play in 42CrMo4 steel treatment? Optimize Strength and Toughness

- What is the effect of high-temperature vacuum on passivation films? Master Refractory Alloy Stability

- What is the difference between sintering and fusion? Solid-State vs. Liquid-Phase Processing Explained

- What is the plasma arc technology? A Guide to Advanced Material Processing

- What is the function of high-temperature furnaces in HPQ processing? Optimize Quartz Calcination & Quenching