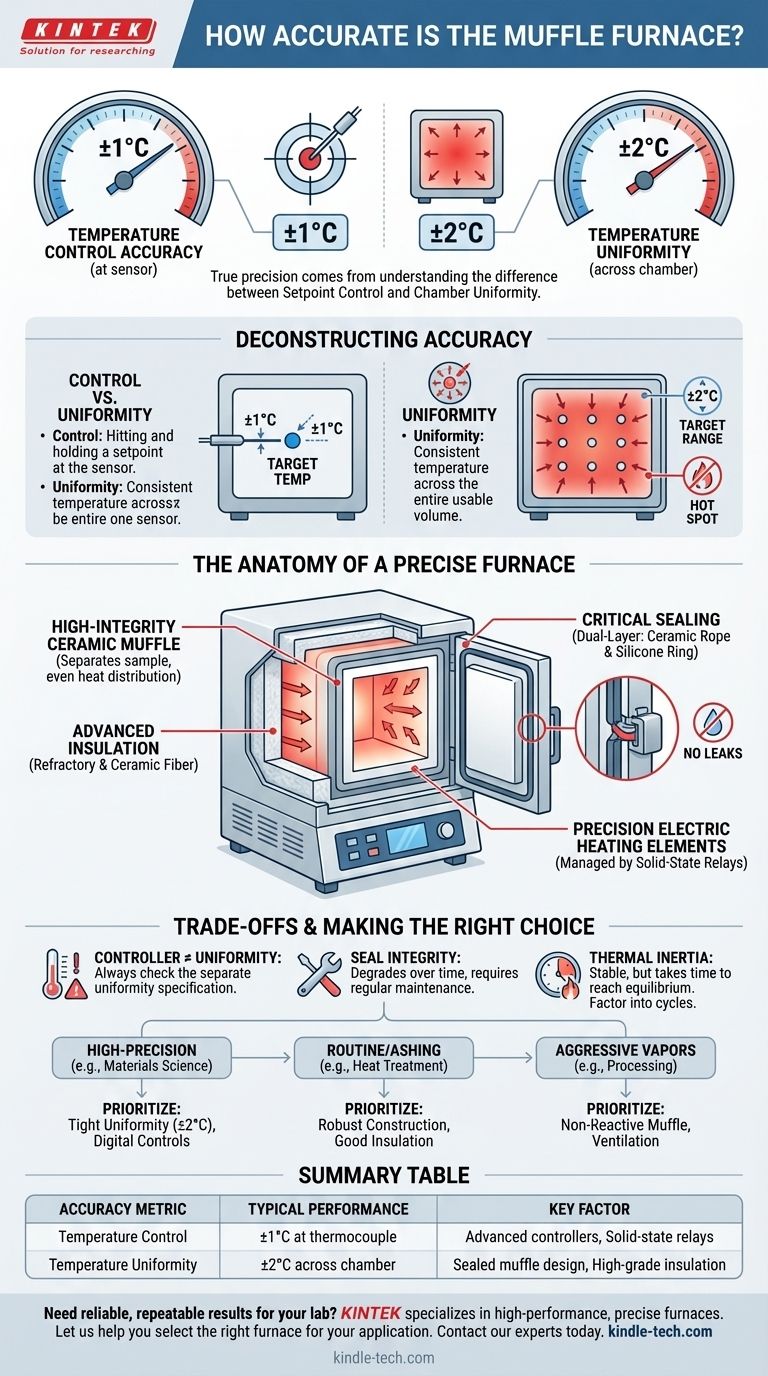

For a high-quality unit, a modern electric muffle furnace can achieve exceptional thermal precision. You can expect a temperature control accuracy of ±1°C at the thermocouple, meaning it can hold its setpoint with very little deviation. Equally important is its temperature uniformity across the entire heating chamber, which can be as tight as ±2°C in a well-designed furnace.

A muffle furnace's accuracy is not a single feature but the result of its core design: isolating the sample within a sealed, uniformly heated chamber. True precision comes from understanding the difference between the furnace's setpoint control and its chamber uniformity, as both are critical for reliable results.

Deconstructing Muffle Furnace Accuracy

To understand what makes a muffle furnace accurate, we need to look beyond a single number. Its precision is an engineered outcome derived from several key principles working in concert.

The Core Principle: Isolation

The defining feature of a muffle furnace is the "muffle" itself—an inner chamber that separates your sample from the heating elements. In modern electric furnaces, this design prevents direct radiant heat from creating hot spots on the sample.

This separation ensures the sample is heated primarily by convection and re-radiation from the chamber walls, leading to a much more homogenous temperature environment. It also protects the heating elements from any aggressive gases or vapors released by the sample during heating.

Temperature Control vs. Temperature Uniformity

It is critical to distinguish between these two aspects of accuracy.

- Temperature Control Accuracy (e.g., ±1°C): This refers to how well the furnace’s controller can maintain the temperature at the specific point where the sensor (thermocouple) is located. It measures the furnace's ability to hit and hold a target.

- Temperature Uniformity (e.g., ±2°C): This measures the maximum temperature variation across the entire usable volume of the heating chamber. Poor uniformity means one part of your sample could be at a significantly different temperature than another, even if the controller reads a stable setpoint.

For most scientific and industrial processes, uniformity is the more critical metric as it dictates whether the entire sample receives the same thermal treatment.

The Role of Electric Heating and Controls

Modern muffle furnaces use high-grade electric heating elements. Unlike older combustion-based models, this eliminates byproducts and allows for far more precise energy input.

These systems are often managed by advanced controllers and solid-state relays, which provide stable, low-noise power to the elements. This prevents the temperature fluctuations common with simpler mechanical relays.

The Anatomy of a Precise Furnace

The physical construction of the furnace is what enables the principles of isolation and uniform heating to become a reality.

High-Integrity Chamber and Muffle

The inner muffle is typically made of a smooth, embedded ceramic material. This material is chosen for its high thermal conductivity to distribute heat evenly and its high resistance to aggressive gases and vapors.

This ensures that the heat from the surrounding elements is absorbed and then radiated uniformly into the chamber.

Advanced Insulation

To maintain a stable temperature, the furnace must minimize heat loss. This is achieved with thick layers of refractory materials and ceramic fiber insulation within the furnace walls and door.

Excellent insulation means the furnace requires less energy to maintain its temperature, contributing to greater stability and lower operational costs.

The Critical Importance of Sealing

A precise furnace is an airtight system. Leaks in the door allow cold ambient air to enter and hot air to escape, creating temperature gradients and ruining uniformity.

High-quality furnaces feature dual-layer door seals, often an inner ceramic fiber rope for high-temperature resilience and an outer silicone rubber ring for an airtight seal. Multi-point locking mechanisms ensure the door is held shut with even pressure, preventing warping and guaranteeing integrity over thousands of cycles.

Understanding the Trade-offs and Limitations

While highly accurate, a muffle furnace is not without its operational realities. Understanding these is key to achieving repeatable results.

Controller Accuracy Isn't Chamber Uniformity

Never assume that a furnace with a precise temperature display is automatically uniform. In lower-quality models, the controller may hold ±1°C at the sensor, but the chamber itself could have variations of ±10°C or more. Always look for a separate temperature uniformity specification.

Seal Integrity Is Paramount

The door seals are consumable components that degrade over time with thermal cycling. A worn or damaged seal is the most common cause of declining performance and accuracy. Regular inspection and maintenance are essential.

Thermal Inertia

The very insulation and mass that make a muffle furnace stable also give it thermal inertia. It cannot change temperatures instantly. Rapid heating is possible, but achieving thermal equilibrium for maximum uniformity takes time. This must be factored into your process cycles.

Making the Right Choice for Your Application

The required level of accuracy depends entirely on your goal. Use these guidelines to determine what to prioritize.

- If your primary focus is high-precision materials science or calibration: Demand a furnace with a specified, tight temperature uniformity (e.g., ±2°C) and invest in a unit with advanced digital controls.

- If your primary focus is general ashing or routine heat treatment: Prioritize robust construction, reliable sealing mechanisms, and good insulation over the absolute tightest control specification.

- If your primary focus is processing materials that release aggressive vapors: Ensure the furnace has a high-quality, non-reactive ceramic muffle and an effective ventilation system to protect the heating elements and ensure longevity.

Ultimately, selecting the right muffle furnace is about matching its design integrity and specified uniformity to the precision your process demands.

Summary Table:

| Accuracy Metric | Typical Performance | Key Factor |

|---|---|---|

| Temperature Control | ±1°C at the thermocouple | Advanced digital controllers and solid-state relays |

| Temperature Uniformity | ±2°C across the chamber | Sealed muffle design and high-grade insulation |

| Critical for | Repeatable scientific and industrial processes | Chamber isolation and door seal integrity |

Need a muffle furnace that delivers reliable, repeatable results for your lab?

At KINTEK, we specialize in high-performance lab equipment designed for precision. Our muffle furnaces are engineered with robust sealing, advanced controls, and uniform heating chambers to ensure your processes—from ashing to materials testing—are accurate and efficient.

Let us help you select the right furnace for your specific application. Contact our experts today to discuss your requirements and see how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is a high-temperature muffle furnace necessary for POM desulfurization catalysts? Master Catalyst Activation

- What role does a high-temperature muffle furnace play in the production of inorganic metal oxide nanofibers?

- What role does a high-temperature muffle furnace play in the final formation of LLZO solid-state electrolytes?

- Why is precise temperature control of a muffle furnace necessary for beta-Fe2O3? Master Metastable Nanostructure Purity

- Why is a high-temperature muffle furnace necessary for VO2+ doped nanopowders? Achieve 1000°C Phase Transformation

- What role does a high-temperature box-type resistance furnace play in Alloy 718 homogenization? | KINTEK Solution

- Why is a high-temperature muffle furnace necessary for molecular sieve production? Unlock High Adsorption Potential

- What is a laboratory oven? A Guide to Precision Heating for Scientific Applications