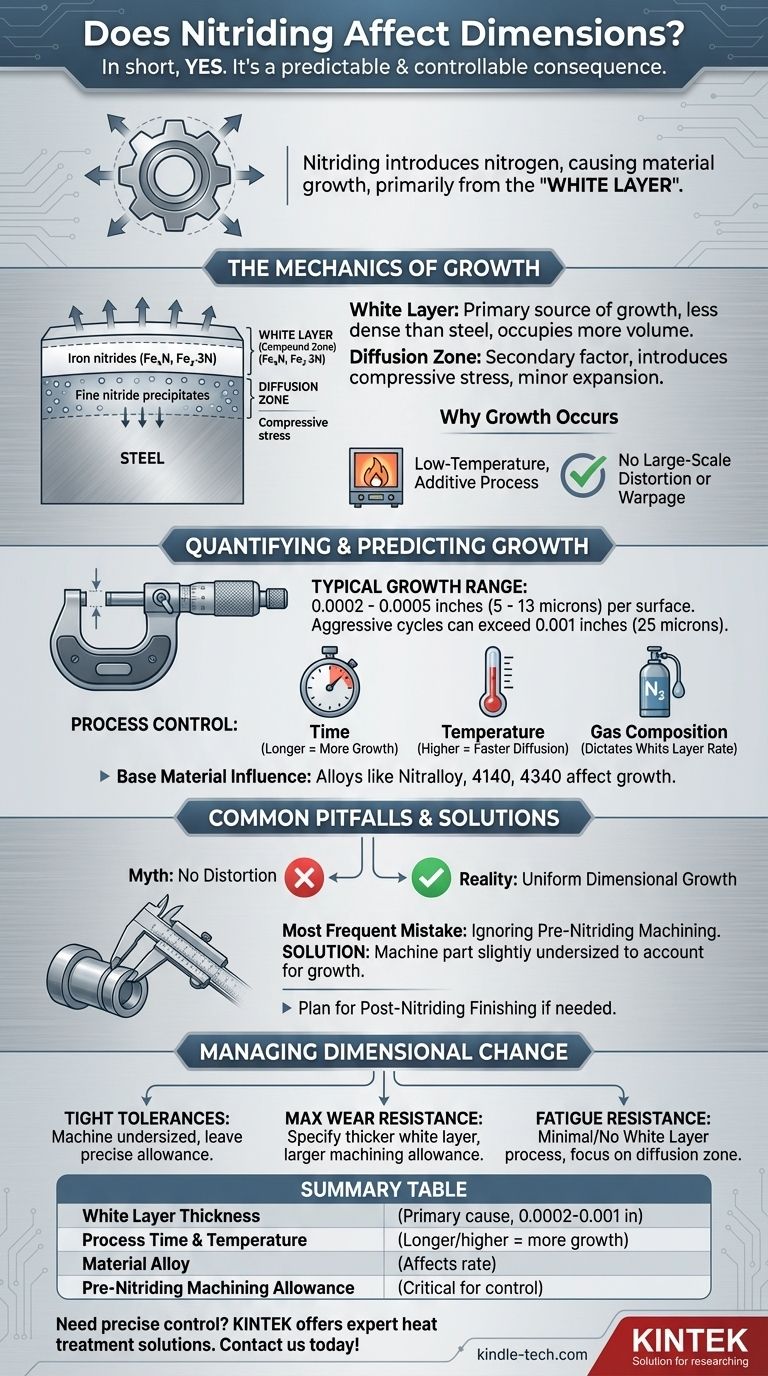

In short, yes. Nitriding is a surface-hardening process that diffuses nitrogen into steel, and this introduction of nitrogen atoms inevitably causes the material to grow. This dimensional change is not a defect but a predictable and manageable consequence of the metallurgical process. The amount of growth is directly related to the process parameters and the desired surface properties.

The core issue is not if dimensions will change, but how to control and account for that change. Nitriding causes predictable growth, primarily from the formation of a "white layer." Engineers must anticipate this by machining parts slightly undersized before treatment to achieve final specifications.

The Mechanics of Dimensional Growth in Nitriding

To control the outcome, you must first understand the mechanism. The growth is not random; it is a direct result of adding new material (nitrogen atoms) into the steel's surface and forming new structures.

The "White Layer": The Primary Source of Growth

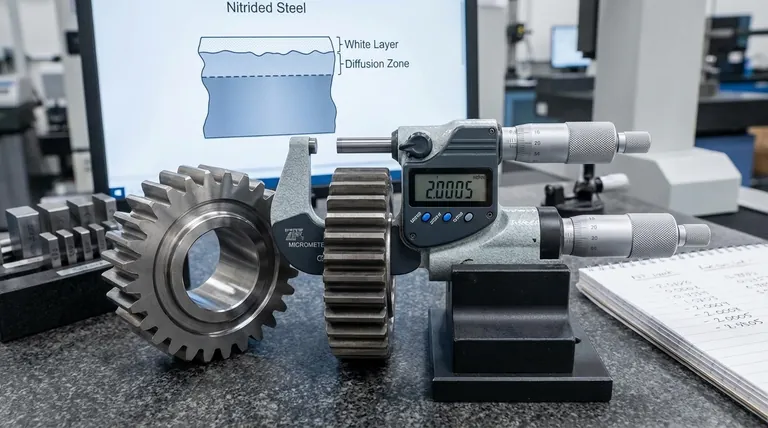

The most significant contributor to dimensional change is the formation of a compound zone on the surface, often called the white layer due to its appearance under a microscope.

This layer consists of iron nitrides (Fe₄N and Fe₂₋₃N), which are new crystalline structures. These nitride compounds are less dense than the underlying steel, meaning they occupy more volume for the same amount of iron atoms, causing the part to grow outward.

The thickness of this white layer is the single biggest factor determining the total amount of growth.

The Diffusion Zone: A Secondary Factor

Beneath the white layer is the diffusion zone. Here, nitrogen atoms have penetrated the steel's crystal lattice but have not formed a full compound layer. Instead, they form very fine, hard nitride precipitates with alloying elements like aluminum, chromium, and molybdenum.

This diffusion introduces compressive stress, which is excellent for fatigue life. While it does contribute to a minor expansion, its effect on the overall external dimensions is much less pronounced than that of the white layer.

Why Growth Occurs (and Not Shrinkage)

Unlike high-temperature quenching and tempering, which can cause both shrinkage and growth due to major phase transformations, nitriding is a low-temperature, additive process.

It occurs below the steel's critical temperature, so there is no large-scale distortion or warpage. You are simply adding nitrogen to the existing structure, which forces it to expand.

Quantifying and Predicting the Growth

The dimensional growth from nitriding is predictable because it is a direct function of the process controls.

Typical Growth Ranges

For most common gas nitriding cycles, you can expect growth on the order of 0.0002 to 0.0005 inches (5 to 13 microns) per surface.

However, this is a general guideline. Aggressive cycles designed for maximum wear resistance can produce growth exceeding 0.001 inches (25 microns).

The Role of Process Control

The amount of growth is directly proportional to the thickness of the white layer. Your heat treater controls this by precisely managing three key variables:

- Time: Longer cycles result in deeper cases and more growth.

- Temperature: Higher temperatures increase the rate of diffusion.

- Gas Composition (Nitriding Potential): The concentration of nitrogen-donating gas in the furnace atmosphere dictates the rate of white layer formation.

By specifying the desired case depth and white layer thickness, you are indirectly defining the expected dimensional change.

The Influence of Base Material

Different steel alloys absorb nitrogen differently. Steels designed for nitriding, such as Nitralloy 135M, contain high levels of aluminum, which is a strong nitride former.

Other common alloys like 4140 or 4340 also nitride well due to their chromium and molybdenum content. The specific alloying elements will influence the final white layer composition and, therefore, the exact amount of growth.

Understanding the Trade-offs and Common Pitfalls

Many engineers are told nitriding causes "no distortion," which is a dangerous oversimplification. It's crucial to understand the nuances.

The Myth of "No Distortion"

Nitriding causes virtually no warpage or shape distortion because it is performed at a low temperature (typically 925-1050°F or 500-565°C). This avoids the thermal shock and phase changes of high-heat quenching that warp long or thin parts.

However, it absolutely causes uniform dimensional growth. Confusing these two concepts is the most common pitfall and leads to out-of-spec parts.

Ignoring Pre-Nitriding Machining

The most frequent mistake is machining a part to its final dimensions before nitriding. The subsequent growth will inevitably push the part outside its tolerance band.

The correct procedure is to finish machine the part slightly undersized, leaving a precise material allowance for the expected growth. This requires close collaboration with your heat treater.

Forgetting Post-Nitriding Finishing

In some applications with extremely tight tolerances, a very thick or slightly porous white layer may need to be lapped or ground off after nitriding.

This step must be planned for. Attempting to remove too much material can compromise the most wear-resistant part of the case-hardened surface.

How to Manage Dimensional Change in Your Design

Instead of viewing growth as a problem, treat it as a controllable design parameter.

- If your primary focus is holding extremely tight tolerances: You must machine the part slightly undersized before nitriding, leaving a precise allowance for the expected growth.

- If your primary focus is maximizing wear resistance: Work with your heat treater to specify a thicker white layer and provide a larger machining allowance to compensate for the increased growth.

- If your primary focus is fatigue resistance with minimal size change: Consider a process that creates a minimal or "no white layer" (achievable with specific gas nitriding controls) and focus on specifying the diffusion zone depth.

By treating dimensional growth not as an accident but as a predictable process variable, you can leverage nitriding to its full potential without compromising precision.

Summary Table:

| Factor | Impact on Dimensional Growth | Typical Range |

|---|---|---|

| White Layer Thickness | Primary cause of growth | 0.0002–0.001 in (5–25 µm) per surface |

| Process Time & Temperature | Longer/higher cycles increase growth | Varies with specification |

| Material Alloy | Affects white layer formation rate | Alloy-dependent (e.g., Nitralloy, 4140) |

| Pre-Nitriding Machining Allowance | Critical for final tolerance control | Must be calculated based on expected growth |

Need precise control over nitriding outcomes for your lab components?

KINTEK specializes in lab equipment and consumables, offering expert solutions for heat treatment processes like nitriding. Whether you're working with precision tools, molds, or high-wear components, we provide the equipment and support to ensure dimensional stability and superior surface hardness.

📞 Contact us today via our contact form to discuss how our nitriding expertise can enhance your lab's capabilities and deliver reliable, repeatable results for your most demanding applications.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is the process of vacuum brazing? Achieve High-Purity, Strong Metal Joining

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond