Yes, silicon carbide (SiC) possesses exceptionally high thermal conductivity. This property, combined with its excellent mechanical strength and chemical stability at high temperatures, is a primary reason it is a critical material in many advanced industrial and high-technology fields. It is a standout among ceramic materials for its ability to manage heat effectively.

While silicon carbide's thermal conductivity is excellent—often rivaling or surpassing that of many metals—its actual performance is critically dependent on the material's purity and specific manufacturing method. Understanding this distinction is key to selecting the right grade of SiC for your application.

A Framework for "High" Thermal Conductivity

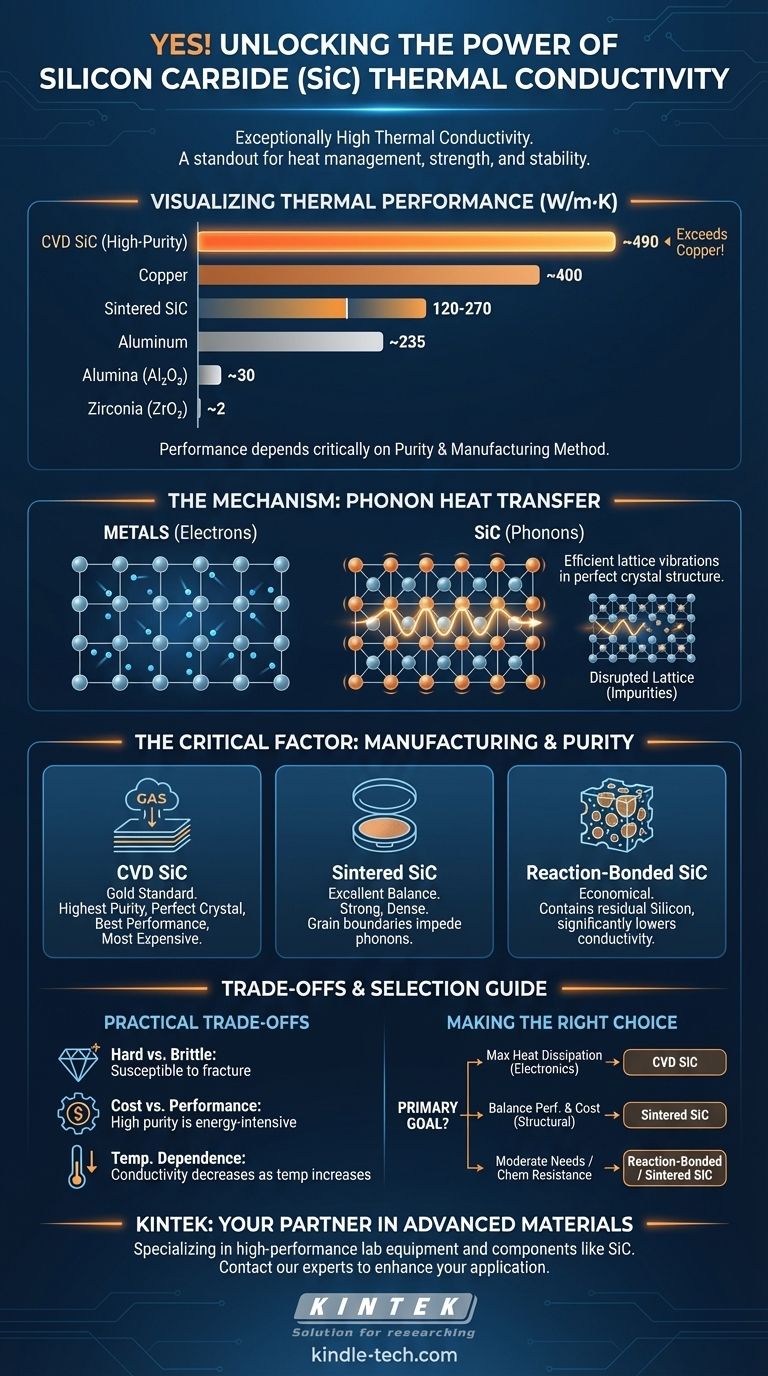

To appreciate why silicon carbide is so effective, it's useful to compare its thermal performance against other well-known materials. The efficiency of heat transfer is measured in watts per meter-Kelvin (W/m·K).

Comparison with Metals

Metals like copper (~400 W/m·K) and aluminum (~235 W/m·K) are famous for their high thermal conductivity. They transfer heat primarily through the movement of free electrons.

High-purity, single-crystal silicon carbide can achieve thermal conductivity values up to ~490 W/m·K, exceeding even copper. More common commercial grades still offer impressive performance, often in the range of 120 to 270 W/m·K.

Comparison with Other Ceramics

Silicon carbide dramatically outperforms traditional ceramics. For example, alumina (Al₂O₃) has a thermal conductivity of only ~30 W/m·K, and zirconia (ZrO₂) is even lower at ~2 W/m·K.

This makes SiC the material of choice when you need the physical and chemical resilience of a ceramic but the thermal performance closer to a metal.

The Role of Crystalline Structure

Unlike metals, ceramics like SiC transfer heat through lattice vibrations, known as phonons. The strong, rigid covalent bonds in silicon carbide's crystal structure allow these vibrations to travel through the material with very little resistance.

Any disruption to this perfect crystal lattice—such as impurities or grain boundaries—will scatter these phonons and reduce thermal conductivity.

The Critical Factor: Manufacturing and Purity

The term "silicon carbide" describes a family of materials, not a single substance. The method used to create the SiC component has the largest impact on its final thermal properties.

Chemical Vapor Deposition (CVD) SiC

CVD silicon carbide is produced by depositing layers of the material from a gas phase. This process creates a theoretically dense and extremely pure form of SiC with a near-perfect crystal structure.

This is the "gold standard" for thermal management, consistently delivering the highest conductivity values. It is also the most expensive.

Sintered and Reaction-Bonded SiC

Sintered silicon carbide is made by pressing SiC powder together at high temperatures until the grains fuse. While strong and dense, the grain boundaries and any necessary sintering aids impede phonon transport, lowering thermal conductivity compared to CVD SiC.

Reaction-bonded silicon carbide involves infiltrating a porous carbon or SiC preform with molten silicon. The resulting material contains residual silicon, which significantly lowers its overall thermal conductivity.

Understanding the Trade-offs

Silicon carbide is a high-performance material, but its advantages come with practical limitations that must be considered.

Hardness vs. Brittleness

As noted in its general properties, SiC is extremely hard and resistant to wear, but it is also brittle. Unlike a metal that will bend or deform under stress, a ceramic will fracture.

This requires careful engineering consideration in applications subject to mechanical or thermal shock.

Manufacturing Complexity and Cost

Creating high-purity, high-performance silicon carbide components is an energy-intensive and complex process. The cost of raw materials and processing makes CVD SiC significantly more expensive than most metals and other ceramics.

Sintered and reaction-bonded grades offer a more economical compromise but at the cost of reduced thermal and mechanical performance.

Temperature Dependence

The thermal conductivity of silicon carbide is not constant; it decreases as temperature increases. While it maintains good conductivity at high temperatures, this behavior is the opposite of many metals and must be accounted for in thermal modeling for high-temperature applications.

Making the Right Choice for Your Application

Selecting the correct grade of silicon carbide depends entirely on your primary engineering goal and budget.

- If your primary focus is maximum heat dissipation for sensitive electronics: You must use high-purity CVD silicon carbide to achieve the necessary performance.

- If your primary focus is a balance of thermal performance and cost for structural components: Sintered silicon carbide provides excellent properties and is a more practical and economical choice.

- If your primary focus is high-temperature chemical resistance with moderate thermal needs: A reaction-bonded or sintered grade of SiC is often sufficient and highly cost-effective for parts like furnace fixtures or chemical pump seals.

Ultimately, silicon carbide provides an unparalleled combination of thermal, mechanical, and chemical properties, making it an essential tool for solving the most demanding engineering challenges.

Summary Table:

| Material | Typical Thermal Conductivity (W/m·K) | Key Characteristics |

|---|---|---|

| CVD Silicon Carbide | Up to ~490 | Highest purity, best thermal performance, most expensive |

| Sintered Silicon Carbide | 120 - 270 | Excellent balance of thermal performance, strength, and cost |

| Reaction-Bonded SiC | Lower than sintered | Good chemical resistance, contains residual silicon |

| Copper (for comparison) | ~400 | High conductivity, but lacks high-temperature stability |

| Alumina (Al₂O₃) | ~30 | Standard ceramic, much lower thermal conductivity |

Need a material that can handle extreme heat and stress?

Silicon carbide's exceptional thermal conductivity, strength, and chemical stability make it the ideal solution for demanding applications in semiconductor processing, aerospace, and advanced manufacturing. The right grade of SiC is critical for your project's success.

KINTEK specializes in high-performance lab equipment and consumables, including components crafted from advanced materials like silicon carbide. Our expertise can help you select the optimal material for your specific thermal management and structural needs.

Contact our experts today to discuss how silicon carbide can enhance your application's performance and reliability.

Visual Guide

Related Products

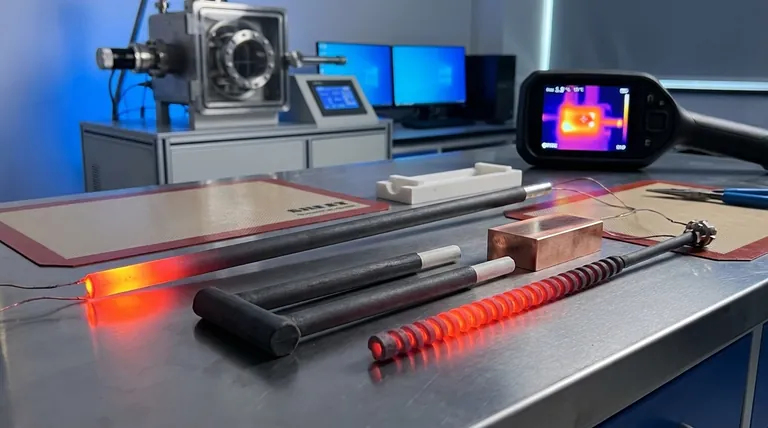

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the characteristics of sintered ceramics? Achieve High-Performance with Engineered Materials

- Why is alumina used in furnaces? Achieve Unmatched Heat Resistance and Purity

- What are the process advantages of selecting an alumina plate for CuO nanofilm synthesis? Achieve Superior Purity

- Why are porous ceramic filters utilized in methane pyrolysis? Protect Your Assets with High-Precision Filtration

- What are the different types of silicon carbide? A Guide to Polytypes, Manufacturing, and Applications

- What are the drawbacks of tungsten carbide? Understanding the Brittleness vs. Hardness Trade-off

- How do ceramic insulators contribute to SHS experimental safety? Enhance Your Lab’s Ignition Precision and Protection

- What temperature is alumina fired at? Unlock the Key to Perfect Ceramic Sintering