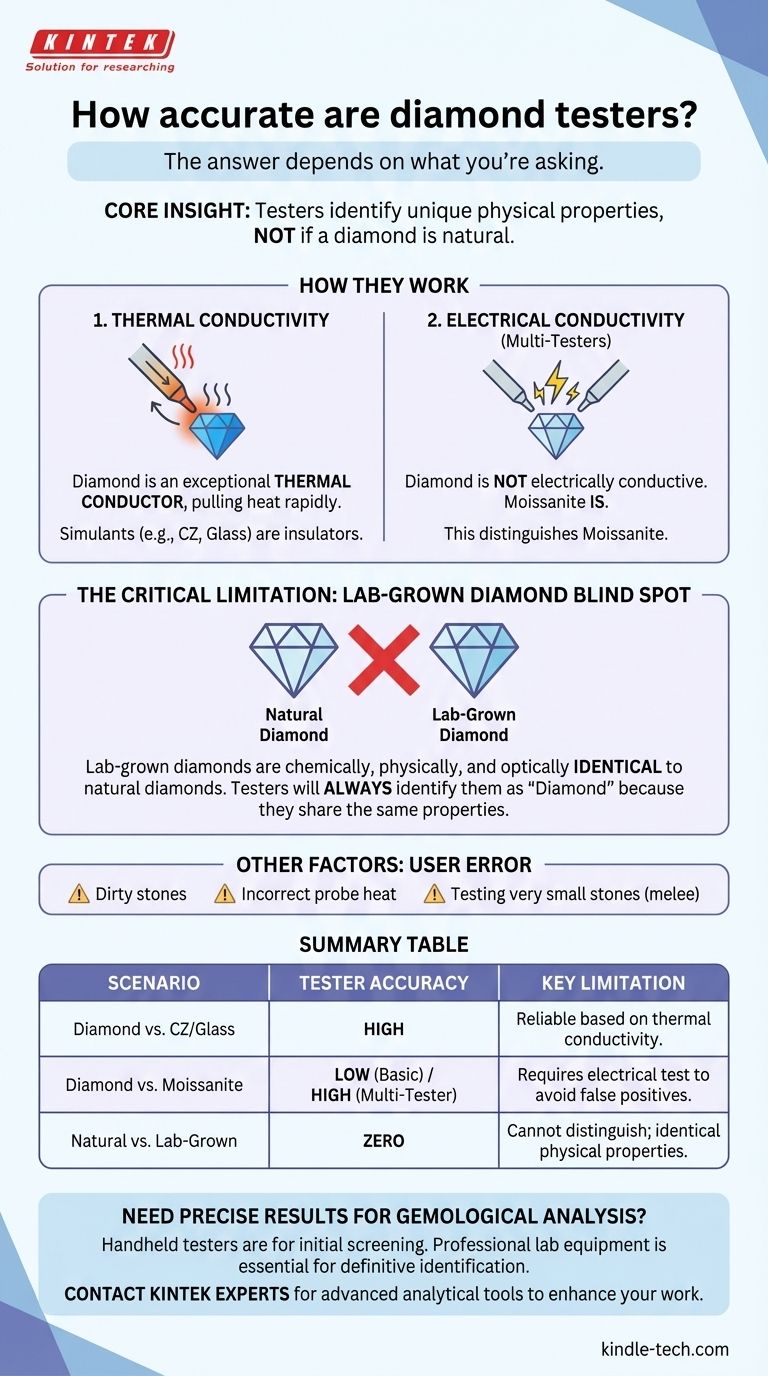

At their core, handheld diamond testers are highly accurate for their specific purpose: identifying a material with the unique physical properties of a diamond. They reliably distinguish diamonds from common simulants like cubic zirconia or glass. However, their accuracy plummets when faced with materials that mimic a diamond's key characteristics, such as moissanite and, most importantly, lab-grown diamonds.

A diamond tester doesn't answer "Is this a natural diamond?" It only answers "Does this material conduct heat and electricity like a diamond?" Understanding this distinction is the key to using them correctly and knowing their absolute limits.

How Diamond Testers Actually Work

To understand their accuracy, you must first understand what these devices measure. They are not magic wands; they are simple scientific instruments testing one or two specific physical properties.

The Primary Test: Thermal Conductivity

Most standard diamond testers are essentially sophisticated thermal probes. The device's heated metal tip is pressed against the gemstone being tested.

Diamonds are exceptional thermal conductors, meaning they pull heat away from the probe at a very rapid and measurable rate. Most common diamond fakes, like cubic zirconia (CZ), glass, or sapphire, are thermal insulators and do not conduct heat well.

The tester measures this rate of heat transfer. If it detects the rapid heat loss characteristic of a diamond, it signals "diamond."

The Secondary Test: Electrical Conductivity

The thermal test has a major flaw: moissanite, a common and convincing diamond simulant, is also an excellent thermal conductor. A basic thermal tester will incorrectly identify moissanite as a diamond.

To solve this, more advanced "multi-testers" were developed. These devices also perform an electrical conductivity test.

Diamond is not electrically conductive. Moissanite, however, is. After confirming high thermal conductivity, a multi-tester will check electrical properties. If it detects electrical conductivity, it will correctly identify the stone as moissanite, not diamond.

The Critical Limitations You Must Understand

The accuracy of a diamond tester is entirely dependent on what you are testing it against. While effective in some scenarios, they have critical blind spots.

The Lab-Grown Diamond Blind Spot

This is the most significant limitation of all handheld testers. Lab-grown diamonds are not simulants; they are chemically, physically, and optically identical to natural diamonds.

Because they have the same crystal structure and carbon composition, they possess the exact same thermal and electrical properties as a mined diamond.

Therefore, a diamond tester will always identify a lab-grown diamond as a diamond. It has no way to distinguish between a stone grown in a lab and one mined from the earth.

User Error and Conditions

The accuracy of a test can be compromised by simple mistakes. Testing a dirty stone can provide a false reading, as can not waiting for the device's probe to properly heat up.

Furthermore, testing very small stones (melee) can be difficult, as the probe may touch the metal setting, which will disrupt the thermal reading.

Understanding the Trade-offs

A diamond tester is a tool for initial screening, not for final appraisal. Its value is determined by what you need to know.

High Accuracy for Common Simulants

For quickly sorting genuine diamonds from a pile of low-cost fakes like glass, white sapphire, or cubic zirconia, a thermal tester is extremely effective and accurate. It accomplishes this specific task very well.

No Insight into Diamond Quality

A tester tells you nothing about the stone's cut, color, clarity, or carat weight (the 4Cs). A heavily included, poorly colored natural diamond will test as "diamond" just as a flawless one will.

Inability to Determine Origin

This is the key trade-off. You gain speed and portability at the complete loss of a crucial piece of information: provenance. A tester cannot tell you if the diamond is natural or lab-created, which has significant implications for value and disclosure. For that, you need advanced spectroscopic equipment found only in gemological laboratories.

Making the Right Choice for Your Goal

Use the tester that aligns with the question you are actually asking.

- If your primary focus is screening for obvious fakes: A standard thermal diamond tester is a reliable and cost-effective tool for separating diamonds from cubic zirconia, glass, and other common simulants.

- If your primary focus is distinguishing diamond from moissanite: You must use a "multi-tester" that checks for both thermal and electrical conductivity.

- If your primary focus is confirming a diamond is natural and not lab-grown: No handheld tester can help you. The stone must be sent to a professional gemological laboratory for definitive identification.

Ultimately, a diamond tester is an excellent tool for a first-pass identification, but it is not a substitute for a professional gemological report.

Summary Table:

| Scenario | Tester Accuracy | Key Limitation |

|---|---|---|

| Diamond vs. CZ/Glass | High | Reliably distinguishes based on thermal conductivity. |

| Diamond vs. Moissanite | Low (Basic Tester) / High (Multi-Tester) | Requires electrical conductivity test to avoid false positives. |

| Natural vs. Lab-Grown Diamond | Zero | Cannot distinguish; they have identical physical properties. |

Need precise, reliable results for your gemological analysis?

While handheld testers are great for initial screening, professional-grade lab equipment is essential for definitive identification and quality assessment. KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of gemologists and research laboratories.

Contact our experts today to find the right analytical tools to enhance the accuracy and efficiency of your work.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- What are 3 benefits of biomass energy? Turn Waste into Renewable Power

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are the waste products of biomass? Uncover Byproducts from Ash to Biochar

- What is batch pyrolysis? A Start-Stop Process for Flexible Waste Conversion

- What are the different methods of cooling after heat treatment? A Guide to Quenching for Optimal Metal Properties

- What kind of gas is used in the sputtering process? Optimize Your Thin-Film Deposition

- How bio-oil can be used as energy source? Unlock Renewable Power from Biomass

- What are the advantages of electron beam hardening? Achieve Superior Precision and Speed