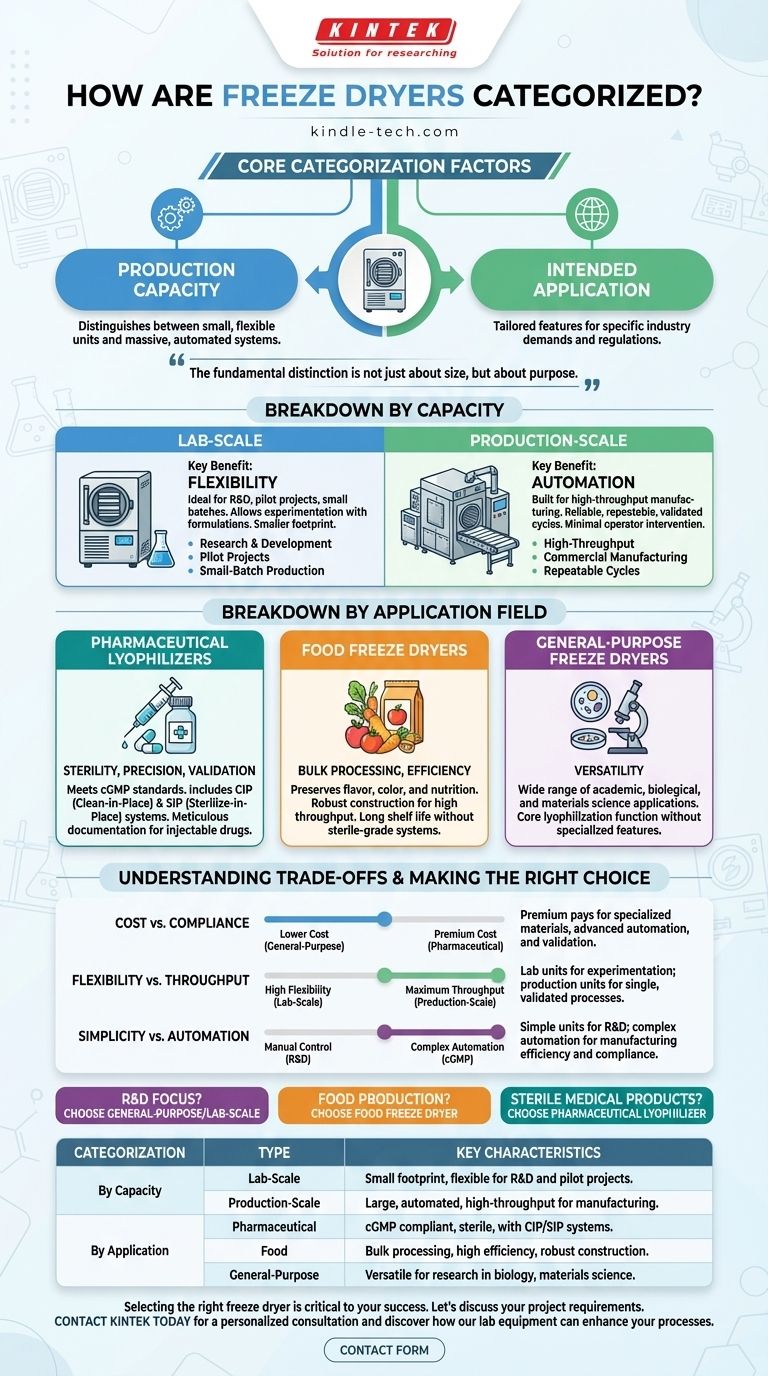

At its core, a freeze dryer is categorized by two primary factors: its production capacity and its intended application. This dual classification system helps distinguish between a small, flexible unit used for research and a massive, automated system designed for industrial manufacturing.

The fundamental distinction is not just about size, but about purpose. Understanding whether your need is driven by experimental flexibility (lab-scale), high-volume output (production-scale), or stringent regulatory compliance (pharmaceutical vs. food) is the key to selecting the right equipment.

Categorization by Production Capacity

The most immediate and obvious distinction between freeze dryers is their size and the volume of product they can process in a single batch. This separates the market into two clear segments.

Lab-Scale Freeze Dryers

These are smaller units designed for research and development (R&D), pilot projects, or small-batch production.

Their primary advantage is flexibility. Researchers can easily experiment with different product formulations and drying cycles without committing large amounts of material.

These systems typically have a smaller footprint, making them suitable for placement in a laboratory environment.

Production-Scale Freeze Dryers

These are large, industrial machines built for high-throughput manufacturing. Their goal is to process the maximum amount of product consistently and efficiently.

Automation is a key feature, with systems designed for repeatable, validated cycles that run with minimal operator intervention.

They are engineered for reliability and are the workhorses of commercial manufacturing in the food and pharmaceutical industries.

Categorization by Application Field

Beyond sheer size, freeze dryers are engineered with specific features tailored to the demands and regulations of different industries.

Pharmaceutical Lyophilizers

These machines are designed to meet the strictest standards of the pharmaceutical industry, such as Current Good Manufacturing Practices (cGMP).

The focus is on sterility, precision, and process validation. They often include advanced features like Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems to ensure the product is free from contamination.

Every component and process is meticulously documented to guarantee the safety and efficacy of injectable drugs and other sterile medical products.

Food Freeze Dryers

Food freeze dryers are engineered for bulk processing and efficiency. The primary goals are to preserve the food's flavor, color, and nutritional value while achieving a long shelf life.

While cleanliness is important, they do not require the sterile-grade systems found in pharmaceutical models. The emphasis is on robust construction and high throughput to handle large quantities of product.

General-Purpose Freeze Dryers

This category often overlaps with lab-scale units. They are versatile machines built for a wide range of applications in academic research, biology, or materials science.

They provide the core function of lyophilization without the specialized, and costly, features required for specific industrial or medical applications.

Understanding the Trade-offs

Choosing a freeze dryer involves balancing cost, features, and operational complexity. The right choice for one application is often entirely wrong for another.

Cost vs. Compliance

A pharmaceutical-grade lyophilizer is significantly more expensive than a general-purpose unit of the same size. This premium pays for the specialized materials, advanced automation, and extensive validation documentation required to meet regulatory standards.

Flexibility vs. Throughput

Lab-scale units are designed for experimentation. Production-scale machines are optimized for a single, validated process, sacrificing flexibility for the sake of maximum, repeatable output.

Simplicity vs. Automation

A simple lab unit offers direct, manual control, which is ideal for R&D. In contrast, a production unit's complex automation for cleaning, sterilization, and process control is essential for cGMP compliance and manufacturing efficiency but represents a significant investment.

Making the Right Choice for Your Goal

Your specific objective dictates the type of freeze dryer you need. By clarifying your primary goal, you can easily determine the correct category of equipment.

- If your primary focus is research and development (R&D): A general-purpose, lab-scale freeze dryer provides the necessary flexibility for experimentation at a manageable cost.

- If your primary focus is large-scale food production: A dedicated food freeze dryer engineered for high throughput and operational efficiency is the correct tool.

- If your primary focus is manufacturing sterile medical products: You must select a pharmaceutical lyophilizer that is fully cGMP compliant and equipped for sterile processing.

By first defining your capacity and application needs, you can confidently navigate the options and select the precise freeze dryer for your objective.

Summary Table:

| Categorization | Type | Key Characteristics |

|---|---|---|

| By Capacity | Lab-Scale | Small footprint, flexible for R&D and pilot projects. |

| Production-Scale | Large, automated, high-throughput for manufacturing. | |

| By Application | Pharmaceutical | cGMP compliant, sterile, with CIP/SIP systems. |

| Food | Bulk processing, high efficiency, robust construction. | |

| General-Purpose | Versatile for research in biology, materials science, etc. |

Selecting the right freeze dryer is critical to your success. Whether you need a flexible lab-scale unit for R&D or a high-throughput, cGMP-compliant production lyophilizer, KINTEK has the expertise and equipment to meet your specific laboratory needs. Our team can help you navigate the trade-offs between cost, compliance, and throughput to find your ideal solution.

Let's discuss your project requirements. Contact KINTEK today for a personalized consultation and discover how our lab equipment can enhance your processes.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- How are freeze dryers used in the pharmaceutical industry? Extend Drug Shelf Life & Stability

- What happens during the primary drying phase of freeze drying? Master the Sublimation Process

- What are some other applications of freeze dryers? Preserving Delicate Materials in Tech and Research

- What is the recommended approach to selecting features for a lab freeze dryer? Match Core Performance to Your Application

- What is the main difference between freeze drying and vacuum drying? A Guide to Quality vs. Efficiency