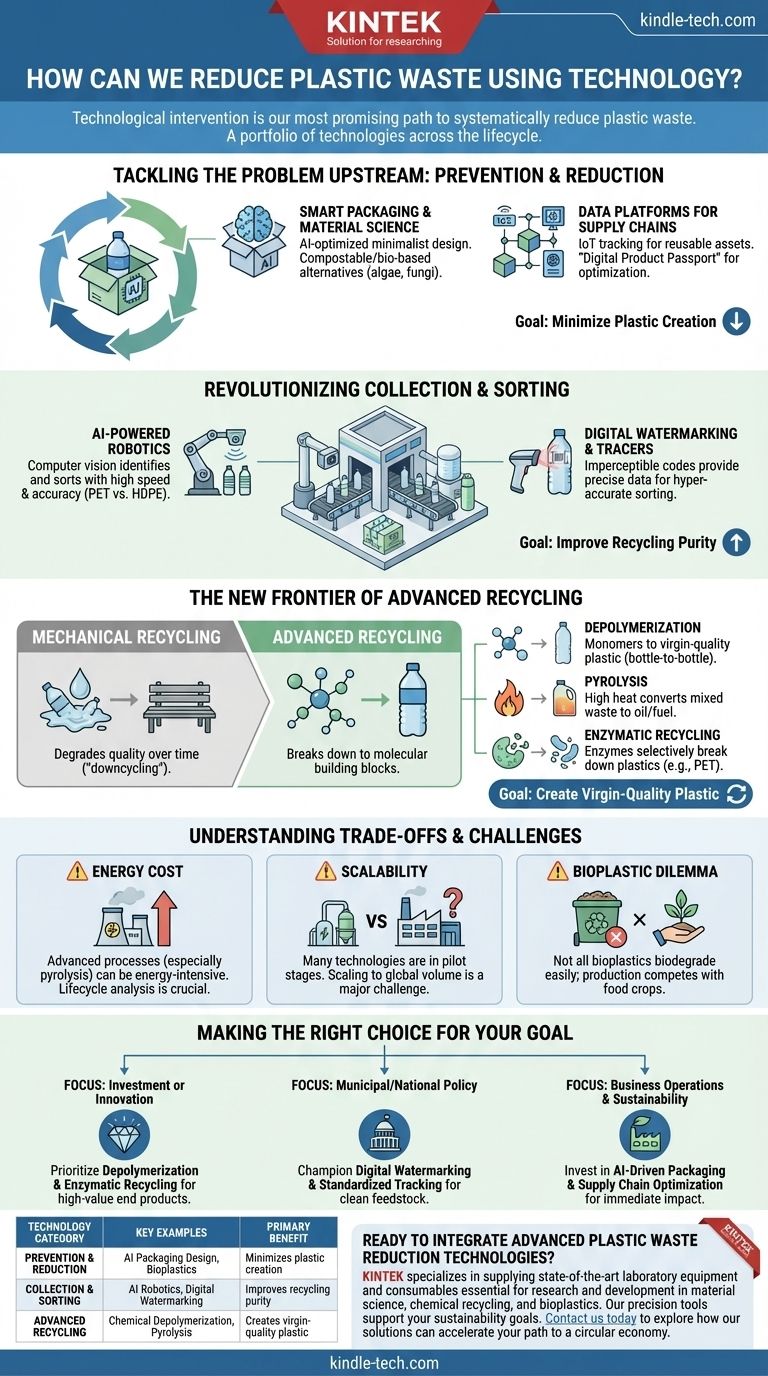

Technological intervention is our most promising path to systematically reduce plastic waste. Key technologies are emerging across the entire plastic lifecycle, from intelligent material reduction and AI-powered sorting to advanced chemical recycling that breaks plastics back down into their original building blocks. These tools are moving the industry beyond simple mechanical recycling and toward a true circular economy.

The most effective strategy is not to search for a single "silver bullet" technology. Instead, the goal is to create a portfolio of technologies that work in concert to prevent, sort, and re-valorize plastic waste at every stage of its lifecycle.

Tackling the Problem Upstream: Prevention and Reduction

The most effective way to reduce plastic waste is to prevent its creation in the first place. Technology provides powerful levers to achieve this at an industrial scale.

Smart Packaging and Material Science

Generative AI and material simulation software now allow engineers to design packaging that uses the absolute minimum amount of plastic necessary to ensure product safety and integrity.

Furthermore, advancements in material science are producing viable, compostable, or bio-based alternatives, such as plastics derived from algae, cornstarch (PLA), or fungi (mycelium).

Data Platforms for Supply Chains

Modern supply chains can use IoT sensors and analytics platforms to track and manage reusable packaging assets, like crates and pallets.

This data-driven approach, often called a "digital product passport," creates a system of accountability and optimization, reducing the need for single-use transit packaging.

Revolutionizing Collection and Sorting

The economic viability of recycling hinges on the ability to produce a pure, high-quality stream of sorted material. Technology is finally cracking this long-standing challenge.

AI-Powered Robotics

Modern recycling facilities (MRFs) are deploying robots equipped with computer vision systems. These robots can identify, categorize, and sort different types of plastics with a speed and accuracy that far surpasses human capabilities.

An AI can instantly distinguish between PET (water bottles) and HDPE (milk jugs) and actuate a robotic arm to place them in the correct bin, dramatically improving the purity of the recycled material.

Digital Watermarking and Chemical Tracers

A breakthrough technology involves embedding an imperceptible digital watermark or chemical tracer onto plastic packaging.

When the package reaches a sorting facility, a high-speed scanner reads this "invisible barcode." It provides precise data on the type of plastic, the presence of multi-layers, and even its original use (e.g., food-grade), enabling hyper-accurate sorting.

The New Frontier of Advanced Recycling

For decades, we have relied on mechanical recycling, which essentially melts and reforms plastic. This process degrades the material's quality over time. Advanced recycling offers a way to break this cycle.

The Limits of Mechanical Recycling

Every time plastic is mechanically recycled, its polymer chains shorten, making it weaker and less valuable. This is why a plastic bottle is often "downcycled" into a park bench, not a new bottle.

Chemical Recycling (Depolymerization and Pyrolysis)

Chemical recycling is a broad term for processes that use heat, chemical solvents, or catalysts to break plastics down into their original molecular building blocks.

Depolymerization breaks polymers back into their base monomers, which can be re-polymerized to create brand-new, virgin-quality plastic with no degradation. This is true "bottle-to-bottle" recycling.

Pyrolysis uses high heat in the absence of oxygen to convert mixed, often contaminated, plastic waste into a synthetic oil or fuel, which can be refined and used to create new plastics or other chemical products.

Enzymatic Recycling

A highly specific form of chemical recycling uses custom-designed enzymes—biological catalysts—to break down certain plastics like PET.

These enzymes selectively "eat" the plastic, decomposing it into its core components, which can then be purified and used to create new, food-grade plastic.

Understanding the Trade-offs and Challenges

While these technologies are powerful, deploying them effectively requires a clear-eyed understanding of their limitations and costs.

The Energy Cost of Advanced Recycling

Chemical recycling processes, particularly pyrolysis, can be highly energy-intensive. A full lifecycle analysis is crucial to ensure the environmental benefit of recycling the plastic outweighs the carbon footprint of the process itself.

The Scalability Question

Many advanced recycling technologies are still in their pilot or early commercial stages. Scaling these complex chemical plants to process the immense volume of global plastic waste is a significant financial and engineering challenge.

The Bioplastic Dilemma

Bioplastics are not a universal solution. Many, like PLA, only properly biodegrade in industrial composting facilities, not in a backyard compost bin or in the open ocean. Their production can also compete with food crops for agricultural land.

Making the Right Choice for Your Goal

The optimal technology depends entirely on your strategic objective within the plastic ecosystem.

- If your primary focus is investment or innovation: Center your efforts on technologies that produce high-purity outputs, such as chemical depolymerization and enzymatic recycling, as these create the highest-value end products.

- If your primary focus is municipal or national policy: Champion the adoption of digital watermarking and standardized tracking to create the clean, sorted feedstock that all other recycling technologies depend on.

- If your primary focus is business operations and sustainability: Invest in upstream AI-driven packaging design and supply chain optimization to reduce your plastic footprint and generate immediate cost savings.

Ultimately, technology's greatest role is to make the circular economy for plastics not just an ideal, but a profitable and practical reality.

Summary Table:

| Technology Category | Key Examples | Primary Benefit |

|---|---|---|

| Prevention & Reduction | AI Packaging Design, Bioplastics | Minimizes plastic creation |

| Collection & Sorting | AI Robotics, Digital Watermarking | Improves recycling purity |

| Advanced Recycling | Chemical Depolymerization, Pyrolysis | Creates virgin-quality plastic |

Ready to integrate advanced plastic waste reduction technologies into your operations? KINTEK specializes in supplying state-of-the-art laboratory equipment and consumables essential for research and development in material science, chemical recycling, and bioplastics. Whether you're innovating in packaging design, scaling up recycling processes, or analyzing material lifecycles, our precision tools support your sustainability goals. Contact us today to explore how our solutions can accelerate your path to a circular economy.

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the primary function of a vacuum drying oven in Pyr-IHF synthesis? Ensure High-Purity Cathode Material Quality

- Does THC evaporate over time? The Truth About Potency Loss and Preservation

- What is the function of a forced air drying oven in the regeneration cycle of dolomite catalysts? Optimize Your Lab Results

- Why is ultrasonic treatment essential for PAAMP-b-PVK synthesis? Achieve Surfactant-Free Emulsion Polymerization

- What materials are sintered steel? Unlock the Secrets of Powder-Based Steel Manufacturing

- Does nanomaterials have potential hazards to human health? Understanding the Risks and Safe Handling

- Which frequency is commonly used for RF sputter deposition? The Global Standard Explained

- How do magnetic or mechanical stirrers affect the degradation efficiency of AOPs? Optimize Mass Transfer for Results