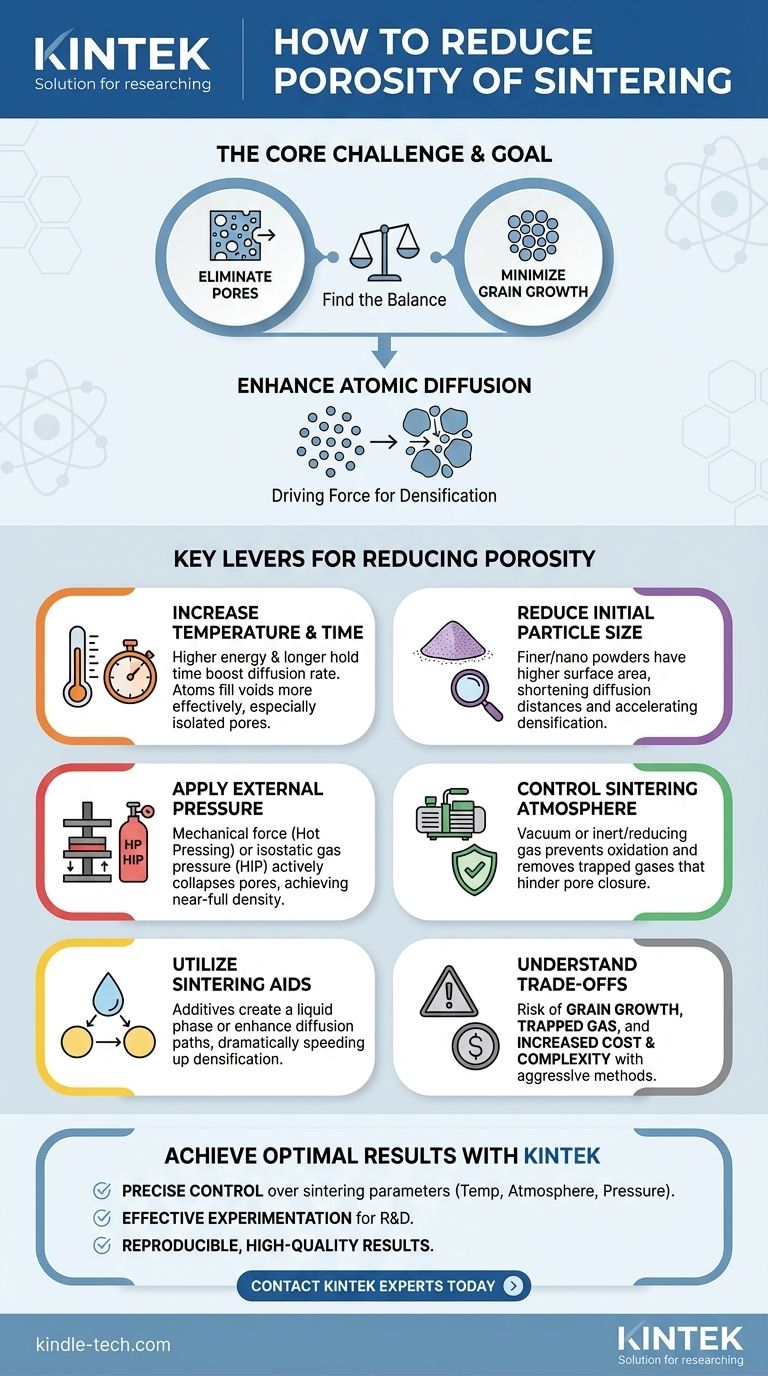

At its core, reducing porosity in a sintered component is achieved by enhancing the diffusion mechanisms that drive material transport to eliminate voids. This is primarily accomplished by increasing sintering temperature and time, using finer starting powders, applying external pressure, and carefully controlling the sintering atmosphere.

The central challenge of sintering is not just eliminating pores, but doing so without causing excessive grain growth, which can compromise the material's final mechanical properties. True optimization lies in finding the right balance between these competing phenomena for your specific application.

The Fundamentals of Densification

Sintering is a thermal process for compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. The goal is densification: the reduction of pore volume.

The Sintering Process and Porosity

Sintering typically occurs in three overlapping stages. In the initial stage, particles form "necks" and begin to bond. In the intermediate stage, these necks grow, and the pores form an interconnected network of channels.

In the final, critical stage, the pore channels pinch off, creating isolated, closed pores. Eliminating these final, isolated pores is the most challenging part of achieving full density.

The Driving Force: Atomic Diffusion

The fundamental mechanism that closes pores is atomic diffusion. Atoms move from areas of high chemical potential (the particle surfaces) to areas of low chemical potential (the necks and pores), gradually filling the empty space.

Higher rates of diffusion lead directly to more effective and rapid densification. The key to reducing porosity is to create conditions that maximize this atomic movement.

Key Levers for Reducing Porosity

To effectively reduce porosity, you must manipulate the process variables that directly influence atomic diffusion and material transport.

Increase Sintering Temperature

Temperature is the most powerful lever you can pull. The rate of atomic diffusion increases exponentially with temperature. A higher sintering temperature gives atoms significantly more energy to move and fill in the voids between particles.

Extend Sintering Time

Time is the second primary parameter. A longer hold time at the peak sintering temperature allows the slow process of diffusion to continue, giving atoms more opportunity to migrate and close off the remaining pores, particularly the isolated ones in the final stage of sintering.

Reduce Initial Particle Size

Using finer, or even nano-sized, starting powders dramatically accelerates densification. Smaller particles have a much higher surface-area-to-volume ratio, which increases the thermodynamic driving force for sintering. The diffusion distances required to close pores are also much shorter.

Apply External Pressure

For applications requiring near-full density, pressure-assisted sintering is the most effective method. Applying external pressure provides a mechanical force that supplements diffusion, actively collapsing pores.

- Hot Pressing (HP): Uniaxial pressure is applied to the powder in a die at sintering temperature.

- Hot Isostatic Pressing (HIP): Isostatic (uniform) gas pressure is applied to the component at high temperature. HIP is exceptionally effective at eliminating the final, closed pores that are difficult to remove with conventional sintering.

Control the Sintering Atmosphere

The furnace atmosphere is critical. An oxidizing atmosphere can form oxide layers on particle surfaces, which act as diffusion barriers and severely hinder densification.

Using a vacuum or an inert/reducing atmosphere (like hydrogen or argon) prevents oxidation and can help remove gases trapped within the pores, allowing them to close.

Utilize Sintering Aids

Sintering aids are small amounts of additives that can dramatically enhance densification.

- Liquid Phase Sintering: The additive melts below the matrix material's sintering temperature, creating a liquid phase. This liquid pulls particles together via capillary force and provides a fast diffusion path, accelerating densification.

- Solid-State Sintering Aids: These additives enhance diffusion along grain boundaries or lattice structures without forming a liquid.

Understanding the Trade-offs

Achieving low porosity is not without its challenges. The most aggressive methods for densification often come with significant trade-offs.

The Risk of Grain Growth

The same conditions that reduce porosity—high temperatures and long times—also promote grain growth. As small grains are consumed by larger ones, the average grain size increases.

This is often undesirable, as fine-grained materials typically exhibit superior strength and hardness (as described by the Hall-Petch relationship). The goal is often to find a "sintering window" that maximizes density while minimizing grain growth.

The Problem of Trapped Gas

If densification at the surface occurs too rapidly, it can pinch off pore channels and trap atmospheric gas inside the material. Once a pore is closed and contains pressurized gas, it becomes nearly impossible to eliminate through diffusion alone.

This is where HIP is particularly valuable, as the high external pressure can overcome the internal gas pressure and force the pore to collapse.

Cost and Complexity

While highly effective, pressure-assisted techniques like HIP are significantly more expensive and complex than conventional pressureless sintering. The equipment is specialized, and cycle times can be long, making it unsuitable for high-volume, low-cost parts.

Making the Right Choice for Your Goal

Your strategy for porosity reduction should be dictated by your material, budget, and performance requirements.

- If your primary focus is maximizing density for critical performance: Pressure-assisted sintering, particularly HIP as a post-sintering step, is the most reliable path to achieving densities above 99.5%.

- If your primary focus is balancing cost and performance: Begin by optimizing conventional sintering. Use the finest practical starting powder and systematically adjust temperature and time to minimize porosity without causing excessive grain growth.

- If you are struggling with a difficult-to-sinter material (e.g., covalent ceramics): Investigate specialized techniques like liquid phase sintering aids or spark plasma sintering (SPS), which uses an electric current to rapidly heat the material.

By understanding these principles, you can move from simply following a recipe to intelligently engineering the microstructure of your material for optimal performance.

Summary Table:

| Method | Key Benefit | Key Consideration |

|---|---|---|

| Increase Temperature/Time | Maximizes atomic diffusion | Risk of excessive grain growth |

| Use Finer Powders | Shorter diffusion distances, higher driving force | Can increase cost and handling complexity |

| Apply External Pressure (HP/HIP) | Actively collapses pores, achieves near-full density | Significant increase in cost and equipment complexity |

| Control Atmosphere | Prevents oxidation, aids pore removal | Requires specialized furnace capabilities |

| Utilize Sintering Aids | Enhances diffusion paths (liquid phase) or rates | Can alter final material composition/properties |

Achieve Optimal Sintering Results with KINTEK

Struggling to balance porosity reduction with grain growth and cost? The right laboratory equipment is crucial for precise control over temperature, atmosphere, and pressure during your sintering process.

KINTEK specializes in advanced lab furnaces and consumables designed to meet the exacting demands of materials research and development. Our solutions help you:

- Precisely control sintering parameters to find the perfect balance between density and microstructure.

- Experiment effectively with different atmospheres and techniques.

- Achieve reproducible, high-quality results for R&D and small-scale production.

Let our experts help you optimize your sintering process. Contact KINTEK today to discuss your specific application and discover the ideal equipment for your laboratory's needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates