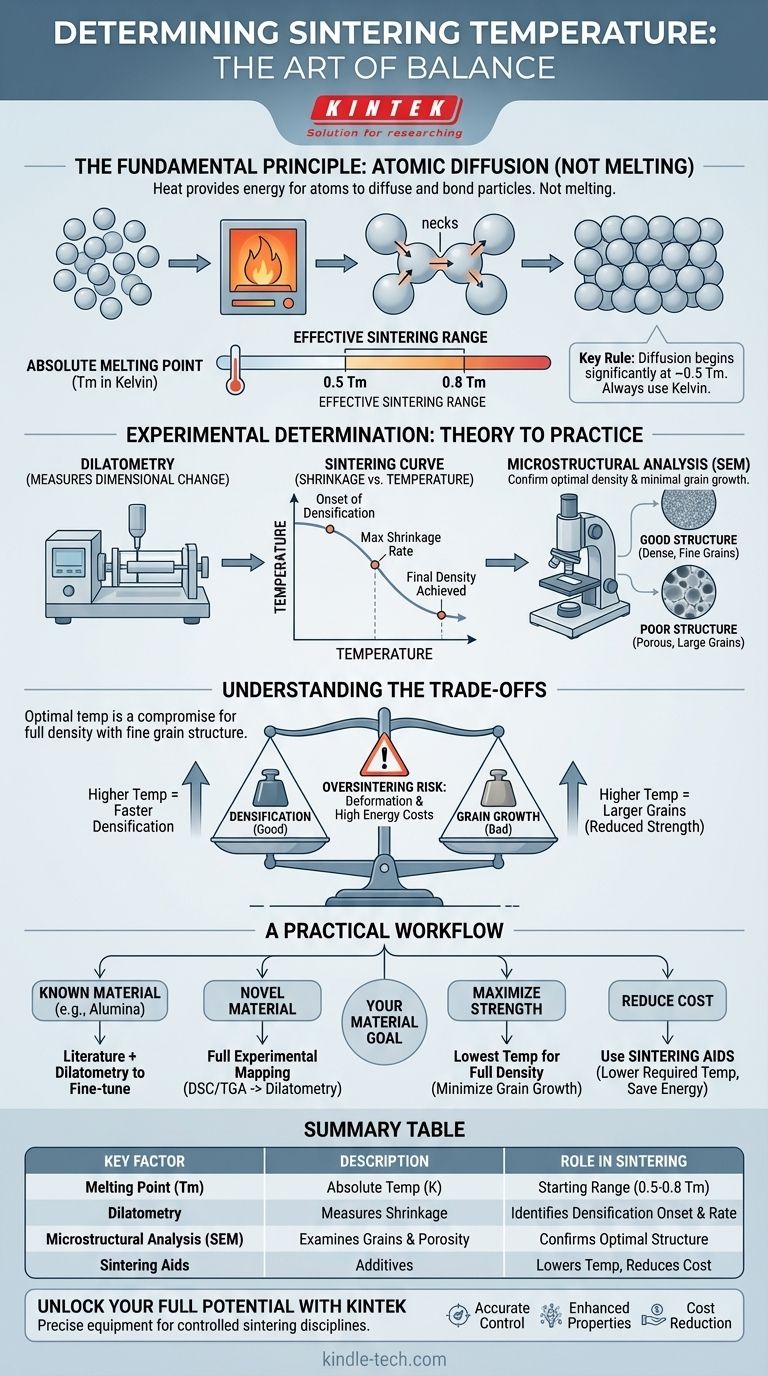

The optimal sintering temperature for any given material is not a single fixed value but a carefully determined range. It is primarily based on the material's absolute melting point (Tm) and is then refined through precise experimental analysis to balance densification against unwanted side effects like excessive grain growth.

The core challenge in sintering is to provide enough thermal energy to drive atomic diffusion and bond particles together, but not so much that you cause melting, deformation, or create a weak microstructure. Therefore, determining the right temperature is a process of finding the optimal balance point for your specific material and performance goals.

The Fundamental Principle: Temperature and Atomic Motion

Sintering as a Diffusion-Driven Process

Sintering is the process of converting a powder compact into a dense, solid body using heat. This transformation is not caused by melting, but by atomic diffusion.

Heating the material gives its atoms the kinetic energy they need to move. They migrate from the surfaces of individual powder particles to the points of contact between them, forming "necks" that grow until the pores between particles are eliminated and a dense solid is formed.

The Role of the Melting Point (Tm)

A reliable starting point for any material is its absolute melting point (Tm), measured in Kelvin. The effective sintering temperature typically falls within the range of 0.5 to 0.8 Tm.

This rule of thumb exists because significant atomic diffusion begins at approximately half the material's melting temperature. Below this range, atomic movement is too slow for densification to occur in a practical timeframe. Above this range, you risk partial melting, rapid grain growth, or loss of the component's shape.

Why Absolute Temperature (Kelvin) Matters

Diffusion is governed by physical laws (like the Arrhenius equation) that depend on absolute temperature. Therefore, all calculations and rules of thumb must use the Kelvin scale, not Celsius or Fahrenheit, to be accurate and comparable across different materials.

From Theory to Practice: Experimental Determination

While the Tm rule provides a starting point, the optimal temperature must be found experimentally. This is most commonly done using a dilatometer.

The Role of Dilatometry

A dilatometer is a precision instrument that measures the dimensional change (shrinkage or expansion) of a material as a function of temperature.

A small sample of the green (unsintered) body is placed in the dilatometer and heated according to a defined program. The instrument records the precise temperature at which shrinkage begins, the rate of shrinkage, and when densification is complete.

Analyzing the Sintering Curve

The data from a dilatometer produces a "sintering curve" that plots shrinkage versus temperature. By analyzing this curve, you can identify:

- Onset of Densification: The temperature where the sample first begins to shrink.

- Maximum Shrinkage Rate: The temperature at which densification is occurring most rapidly. This is often a good indicator of the optimal sintering temperature.

- Final Density: The point where shrinkage stops, indicating that maximum densification has been achieved under those conditions.

Microstructural Analysis

After dilatometry provides a target temperature range, samples are sintered and then examined with a Scanning Electron Microscope (SEM). This visual analysis is crucial to confirm that the chosen temperature yields a good microstructure with minimal residual porosity and a controlled grain size.

Understanding the Trade-offs

Choosing a sintering temperature is an exercise in managing competing factors. An "optimal" temperature is always a compromise.

Densification vs. Grain Growth

This is the central trade-off in sintering. Higher temperatures accelerate densification, which is good. However, they also accelerate grain growth, where smaller grains merge into larger ones.

Excessive grain growth often leads to reduced mechanical properties, such as lower strength and fracture toughness. The goal is to achieve full density with the finest possible grain structure.

The Risk of Oversintering

If the temperature is too high or the hold time is too long, you can enter an "oversintering" regime. This can cause liquid phase formation at grain boundaries, leading to rapid, uncontrolled grain growth and even slumping or deformation of the part.

Energy Costs and Throughput

From a production standpoint, lower sintering temperatures are always better. Every degree you can reduce the peak temperature saves significant energy and cost. Likewise, finding a temperature that achieves full density with a shorter hold time increases factory throughput.

A Practical Workflow for Your Material

Your approach to determining the sintering temperature depends on your specific goal and material system.

-

If you are working with a known material (e.g., Alumina, Steel): Begin by researching established literature values, which will align with the 0.5-0.8 Tm rule. Use this as your starting point for dilatometry to fine-tune the temperature for your specific powder characteristics and desired density.

-

If you are developing a novel material or composite: Your approach must be purely experimental. Start with thermal analysis (DSC/TGA) to identify any phase transitions or reactions, then conduct a series of dilatometry tests across a broad temperature range to map out the sintering behavior.

-

If your primary focus is maximizing mechanical strength: Aim for the lowest possible temperature that achieves full densification to minimize grain growth. This may involve using longer hold times or advanced techniques like two-step sintering.

-

If your primary focus is reducing manufacturing cost: Investigate the use of sintering aids. These are additives that can lower the required sintering temperature by creating a temporary liquid phase or enhancing diffusion, saving both energy and time.

By combining theoretical principles with precise experimental validation, you can transform the process of determining a sintering temperature from an estimate into a controlled engineering discipline.

Summary Table:

| Key Factor | Description | Role in Sintering |

|---|---|---|

| Melting Point (Tm) | Absolute temperature in Kelvin | Provides starting range (0.5-0.8 Tm) for sintering |

| Dilatometry | Measures dimensional change vs. temperature | Identifies onset of densification and maximum shrinkage rate |

| Microstructural Analysis (SEM) | Examines grain size and porosity | Confirms optimal density and minimal grain growth |

| Sintering Aids | Additives that lower required temperature | Reduces energy costs and enhances diffusion |

Unlock the Full Potential of Your Materials with KINTEK

Determining the precise sintering temperature is critical for achieving optimal density, mechanical strength, and cost-efficiency in your lab. At KINTEK, we specialize in providing advanced lab equipment and consumables—including dilatometers for precise thermal analysis and SEM supplies for microstructural validation—to help you master the sintering process.

Our expertise supports researchers and manufacturers in:

- Accurate Temperature Control: Achieve perfect densification without oversintering.

- Enhanced Material Properties: Minimize grain growth for superior strength and durability.

- Cost Reduction: Leverage sintering aids and optimized protocols to save energy and time.

Let KINTEK be your partner in transforming sintering from an estimate into a controlled discipline. Contact us today to discuss how our solutions can elevate your laboratory's capabilities and drive your innovations forward!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the advantages of sintering during metal production? Unlock Design Freedom & Superior Material Properties

- How do high-temperature box resistance furnaces regulate the microstructure of T91 and HT9 steels? Precise Thermal Control

- How is a benchtop laboratory oven utilized in processing spongin-atacamite composites? Achieve Precise Material Drying

- How do high-temperature furnaces and quenching media evaluate Cr/CrxN coatings? Testing Thermal Shock Durability

- What temperature is conventional sintering? Mastering the Key to Dense, Strong Materials

- What role do industrial muffle furnaces play in rice husk ash analysis? Optimizing High-Purity Silica Recovery

- How is a high-temperature box muffle furnace used in the synthesis of Al2(SiO4)O? Master Ceramic Phase Engineering

- What is the objective of sintering? Transforming Powders into High-Performance Solid Parts