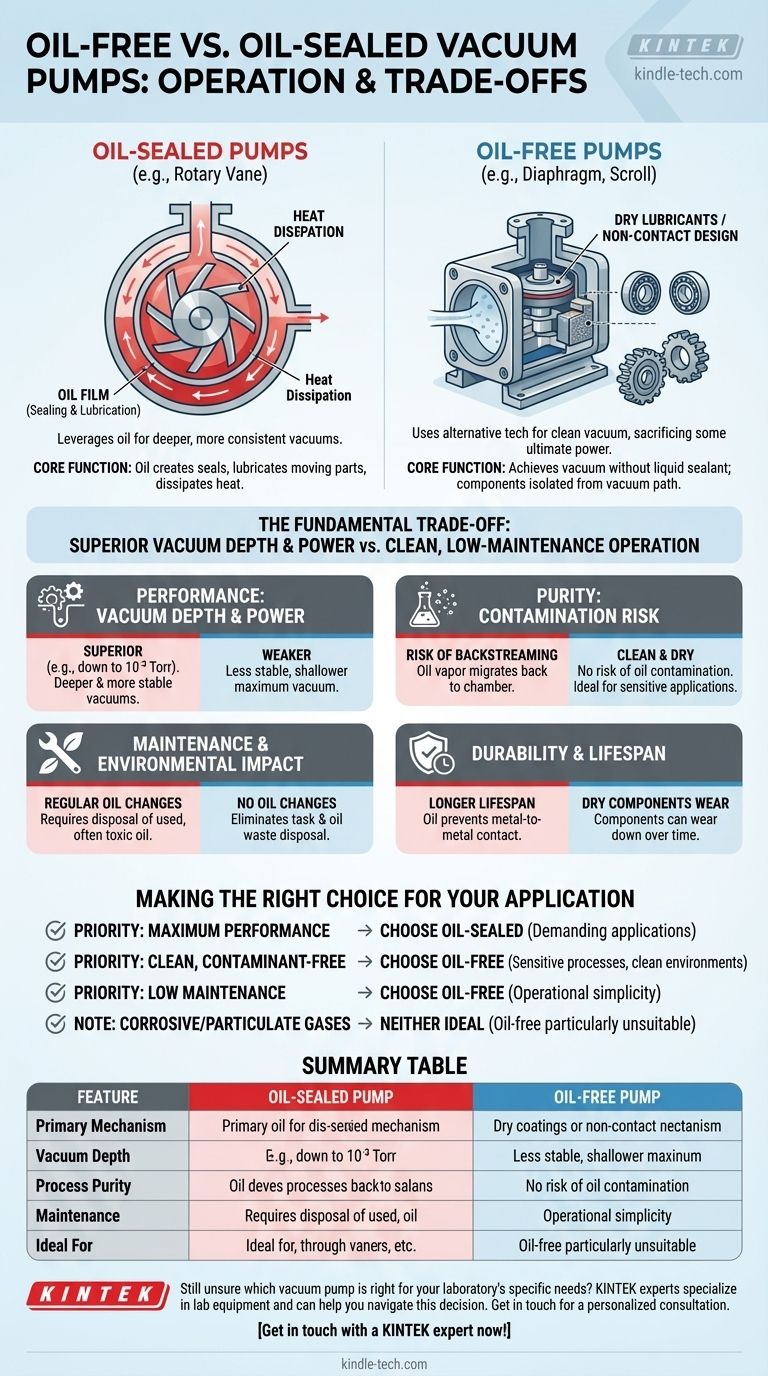

At their core, the operational difference between oil-free and oil-sealed vacuum pumps is simple: one uses oil within the pumping chamber to create seals and lubricate moving parts, while the other does not. Oil-sealed pumps, like rotary vane models, leverage this oil to achieve deeper, more consistent vacuums. In contrast, oil-free pumps use alternative technologies like dry lubricants or non-contact designs to provide a clean vacuum, sacrificing some ultimate power for simplicity and purity.

The choice between an oil-free and an oil-sealed vacuum pump is a fundamental trade-off. You are choosing between the superior vacuum depth and power of an oil-sealed pump and the clean, low-maintenance operation of an oil-free pump.

The Role of Oil in a Vacuum System

To understand the difference in operation, you must first understand the function oil serves in a traditional vacuum pump. It is not merely a lubricant.

The Sealing Mechanism

In an oil-sealed pump, oil is the critical component for creating an effective vacuum. It forms a thin, non-compressible film between moving parts, such as the vanes and the chamber wall in a rotary vane pump. This film seals the microscopic gaps, preventing air from leaking back and compromising the vacuum level.

Lubrication and Heat Dissipation

The oil also provides essential lubrication, preventing metal-to-metal contact between high-speed components. This dramatically reduces wear and extends the pump's operational lifespan. Finally, the oil circulates and helps dissipate the significant heat generated during gas compression.

How Each Pump Type Operates

The presence or absence of oil dictates the entire mechanical design and operational principle of the pump.

Oil-Sealed Pumps: The High-Performance Workhorse

An oil-sealed rotary vane pump is a classic example. As the rotor spins, vanes slide in and out, trapping volumes of gas, compressing them, and expelling them from the outlet. The oil is essential to seal the tips of these vanes against the chamber, enabling the pump to achieve very deep vacuum levels, often down to 10⁻³ Torr.

Oil-Free Pumps: The Clean and Simple Alternative

Oil-free pumps must achieve a vacuum without this liquid sealant. They do this using materials with a low coefficient of friction, such as PTFE or graphite, for their moving parts. Designs like diaphragm or scroll pumps avoid internal contact altogether.

It is important to note that "oil-free" refers to the pumping chamber. The pump's mechanical components, like bearings and gears, are still lubricated, but they are physically isolated from the vacuum path to prevent any contamination of the pumped gas.

Understanding the Key Trade-offs

Your choice will ultimately depend on which set of trade-offs aligns with your application's requirements.

Performance: Vacuum Depth and Power

Oil-sealed pumps are the undisputed leaders in performance. The oil's sealing properties allow them to achieve significantly deeper and more stable vacuums than their oil-free counterparts. Oil-free pumps generally have a weaker maximum vacuum.

Purity: Contamination Risk

This is the primary advantage of an oil-free pump. It provides a completely clean and dry vacuum, which is non-negotiable for sensitive applications like mass spectrometry, semiconductor manufacturing, or medical processes. Oil-sealed pumps always carry a risk of "backstreaming," where oil vapor migrates from the pump back into the vacuum chamber, contaminating the process.

Maintenance and Environmental Impact

Oil-free pumps are far simpler to maintain. They require no regular oil changes, eliminating both the task itself and the need to dispose of used, often toxic, oil waste. This makes them more environmentally friendly and lowers their long-term operational burden.

Durability and Lifespan

Oil-sealed pumps often have a longer lifespan under heavy, continuous use. The oil layer prevents any direct metal-to-metal contact, minimizing wear and tear. The dry-lubricated components of an oil-free pump can wear down over time, eventually requiring replacement.

Making the Right Choice for Your Application

There is no single "best" pump; there is only the best pump for your specific goal.

- If your primary focus is maximum vacuum depth and power: Choose an oil-sealed pump for its superior performance in demanding applications.

- If your primary focus is a clean, contaminant-free process: Choose an oil-free pump to guarantee the purity of your vacuum environment.

- If your primary focus is low maintenance and operational simplicity: Choose an oil-free pump to avoid oil changes and waste disposal.

- If your primary focus is handling corrosive or particulate-laden gases: Neither pump is ideal, but oil-free pumps are particularly unsuitable for these tasks.

Ultimately, selecting the correct pump requires you to clearly define whether your priority is raw performance or process purity.

Summary Table:

| Feature | Oil-Sealed Pump | Oil-Free Pump |

|---|---|---|

| Primary Mechanism | Uses oil for sealing and lubrication | Uses dry lubricants or non-contact design |

| Vacuum Depth | Superior (e.g., down to 10⁻³ Torr) | Weaker, less stable |

| Process Purity | Risk of oil backstreaming and contamination | Clean, dry, and contaminant-free |

| Maintenance | Regular oil changes and waste disposal required | No oil changes, lower long-term maintenance |

| Ideal For | Maximum performance, demanding applications | Sensitive processes, clean environments, low maintenance |

Still unsure which vacuum pump is right for your laboratory's specific needs?

The choice between performance and purity is critical. The experts at KINTEK specialize in lab equipment and consumables, and we can help you navigate this decision. We provide the right vacuum solution—whether oil-sealed for power or oil-free for cleanliness—to ensure your processes run efficiently and reliably.

Contact us today for a personalized consultation and let us help you optimize your lab's performance.

Get in touch with a KINTEK expert now!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- How should an oil-free diaphragm vacuum pump be maintained? A Proactive Guide to Maximize Pump Lifespan

- What is the main characteristic of oil-free diaphragm vacuum pumps? Guaranteeing a Contamination-Free Vacuum

- What factors should be considered when choosing a vacuum pump for laboratory use? Match Your Lab's Needs

- What factors should be considered when selecting an oil-free diaphragm vacuum pump? A Guide to Optimal Performance & Longevity