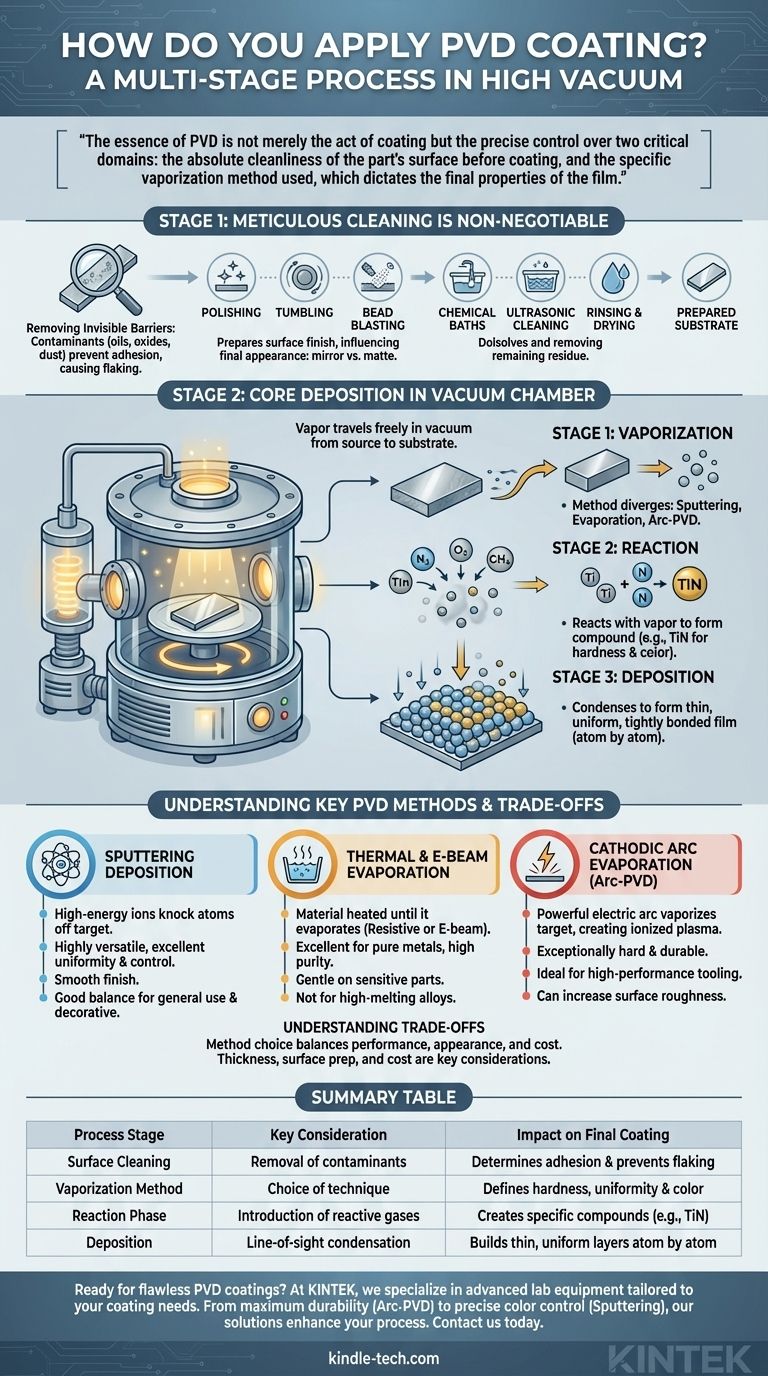

Applying a Physical Vapor Deposition (PVD) coating is a multi-stage process conducted within a high-vacuum environment. It begins with the meticulous cleaning of the substrate, which is then placed in a vacuum chamber. Inside, a solid source material is converted into a vapor, which travels through the vacuum and condenses on the substrate, forming a thin, durable film atom by atom.

The essence of PVD is not merely the act of coating but the precise control over two critical domains: the absolute cleanliness of the part's surface before coating, and the specific vaporization method used, which dictates the final properties of the film.

The Foundation: Why Meticulous Cleaning is Non-Negotiable

The success or failure of a PVD coating is often decided before the part ever enters the coating chamber. The bond between the coating and the substrate is mechanical and atomic; any contamination creates a weak point.

Removing Invisible Barriers

Even a seemingly clean part is covered in contaminants at a microscopic level. These can include oils, organic films, dust, oxides, and residue from manufacturing processes like EDM. If not removed, these contaminants will prevent the coating from adhering properly, leading to flaking, poor durability, and inconsistent appearance.

Common Cleaning Techniques

The cleaning protocol is tailored to the substrate material and the desired final appearance. It typically involves a multi-step process that can include polishing, tumbling, or bead blasting to achieve the desired surface texture. This is followed by rigorous chemical and ultrasonic cleaning baths to dissolve and remove any remaining organic or particulate matter, followed by rinsing and drying.

Preparing the Surface Finish

The cleaning and preparation stage also sets the final aesthetic. A highly polished part will result in a bright, mirror-like PVD finish, whereas a bead-blasted or tumbled surface will produce a satin or matte finish. The durability can also be affected, as matte finishes tend to show wear less obviously than polished ones.

Inside the Vacuum Chamber: The Core Deposition Stages

Once cleaned and loaded, the parts undergo the PVD process itself, which always happens in a vacuum to allow vapor particles to travel freely from the source to the substrate.

Stage 1: Vaporization

This is the step where different PVD methods diverge. The goal is to convert a solid coating material (known as the "target") into a vapor. The method used to achieve this has the single greatest impact on the coating's characteristics.

Stage 2: Reaction

For many advanced coatings, a reactive gas like nitrogen, oxygen, or methane is introduced into the chamber. This gas reacts with the metal vapor to form a new compound on the substrate's surface. For example, vaporized titanium reacting with nitrogen gas creates the familiar hard, gold-colored Titanium Nitride (TiN). This stage defines properties like hardness and color.

Stage 3: Deposition

The vaporized material travels in a line-of-sight path through the vacuum and condenses onto the cooler surfaces of the parts. This builds the coating one atomic layer at a time, resulting in an extremely thin, uniform, and tightly bonded film.

Understanding the Key PVD Methods

While all PVD processes follow the stages above, the vaporization technique is the defining factor.

Sputtering Deposition

Think of this as atomic billiards. High-energy ions are shot at the target material, physically knocking atoms off its surface. These "sputtered" atoms then deposit onto the substrate. Sputtering is highly versatile and offers excellent control over film thickness and uniformity.

Thermal & Electron-Beam Evaporation

This process is analogous to boiling water. The source material is heated in a high vacuum until it evaporates. The heating can be done with a simple resistive element (Thermal Evaporation) or a highly focused beam of electrons (E-beam PVD). This method is excellent for depositing pure metals, like gold or aluminum.

Cathodic Arc Evaporation (Arc-PVD)

This is a very high-energy process. A powerful electric arc is used to vaporize the material from the target's surface. This creates a dense, highly ionized plasma that results in an exceptionally hard and durable coating. It is a preferred method for high-performance tooling and wear-resistant applications.

Understanding the Trade-offs

Choosing the right PVD process involves balancing competing priorities of performance, appearance, and cost.

Method vs. Desired Properties

Arc-PVD creates the hardest coatings but can sometimes introduce microscopic droplets that increase surface roughness. Sputtering is smoother and more controlled but may deposit at a slower rate. Thermal evaporation is clean and simple but is not suitable for high-melting-point or complex alloy materials.

Thickness vs. Functionality

A thicker coating is generally more durable, but only up to a point. Excessively thick coatings can become brittle, alter the fine tolerances of a part, or build up internal stress and crack. The ideal thickness is a balance between wear resistance and the part's mechanical requirements.

Surface Preparation vs. Cost

An exhaustive, multi-step cleaning and polishing process yields a superior finish and adhesion. However, each step adds significant time and cost to the project. It is crucial to match the level of preparation to the application's demands.

How to Specify the Right PVD Process

Your choice should be driven by the primary goal for your component.

- If your primary focus is maximum durability and wear resistance: Specify a high-energy process like Arc-PVD and a robust multi-stage cleaning protocol for the best possible adhesion.

- If your primary focus is decorative appearance and color consistency: Sputtering is often the best choice for its excellent control over uniformity and surface finish.

- If your primary focus is coating a pure metal on a sensitive electronic or optical part: Thermal or E-beam Evaporation provides a high-purity film with lower energy, minimizing potential damage to the substrate.

- If your primary focus is a balanced, cost-effective solution for general use: Sputtering often provides the best combination of performance, versatility, and cost for a wide range of applications.

Understanding these core principles allows you to move beyond simply asking for a coating and begin specifying the precise outcome your project requires.

Summary Table:

| Process Stage | Key Consideration | Impact on Final Coating |

|---|---|---|

| Surface Cleaning | Removal of oils, oxides, and contaminants | Determines adhesion strength and prevents flaking |

| Vaporization Method | Choice of sputtering, evaporation, or arc-PVD | Defines hardness, uniformity, and color consistency |

| Reaction Phase | Introduction of reactive gases (e.g., nitrogen) | Creates compound coatings like TiN for specific properties |

| Deposition | Line-of-sight condensation in vacuum | Builds thin, uniform layers atom by atom |

Ready to achieve flawless PVD coatings for your components? At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific coating needs. Whether you require maximum durability with Arc-PVD or precise color control with sputtering, our expertise ensures optimal results for your laboratory applications. Contact us today to discuss how our solutions can enhance your coating process and deliver superior performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells