To properly place a sample in a muffle furnace, you must first ensure it is in a heat-resistant container, such as a ceramic or porcelain crucible. With the power off, use long tongs to carefully position the container in the center of the furnace chamber, taking care not to touch the temperature sensor at the back. Once the sample is secure, close the door firmly before powering the furnace on.

The goal of proper sample placement is twofold: ensuring your personal safety from extreme heat and potential electric shock, and guaranteeing the accuracy of your results by achieving uniform, consistent heating.

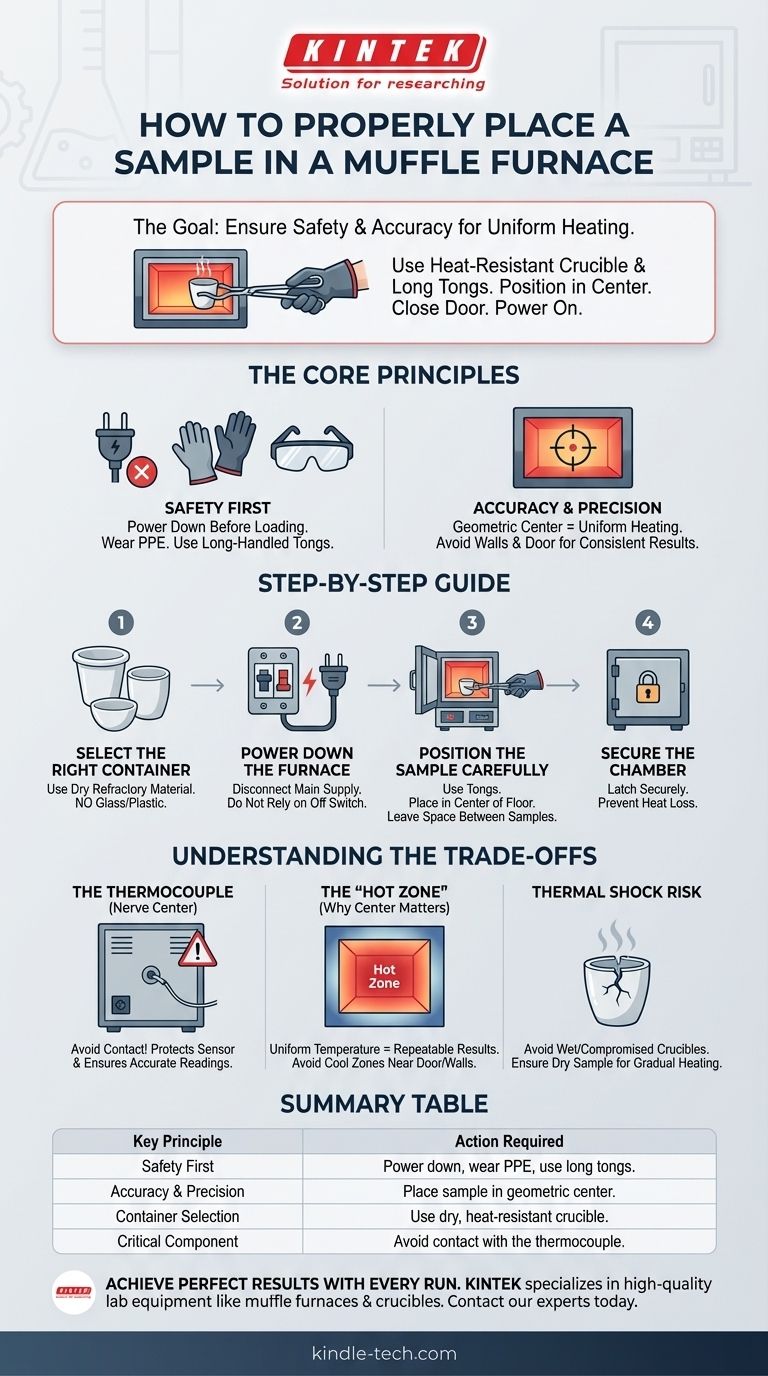

The Core Principles: Safety and Accuracy

Every action you take when using a muffle furnace is guided by the need to protect yourself and your experiment. These are not just rules, but principles that ensure reliable outcomes and a safe lab environment.

Prioritizing Personal Safety

Before you even open the furnace door, your safety is the top priority. Always wear appropriate Personal Protective Equipment (PPE), including heat-resistant gloves and safety glasses.

The most critical safety step is to cut the power supply before loading or unloading a sample. This eliminates the risk of electric shock from contact with the heating elements.

Use long-handled tongs or forceps to handle crucibles and samples. This maintains a safe distance, protecting you from severe burns, as the furnace's interior and door can remain dangerously hot even when powered down.

Ensuring Experimental Accuracy

For your results to be valid, the sample must be heated uniformly. The most stable and consistent temperature in a muffle furnace is at its geometric center.

Placing samples randomly, too close to the door, or near the walls can expose them to temperature gradients. This uneven heating can skew your results, especially in sensitive processes like ashing or material analysis.

A Step-by-Step Guide to Loading Your Sample

Follow this sequence to ensure safety and precision every time you load a sample.

Step 1: Select the Right Container

Your sample must be placed in a container made of refractory material. This means it can withstand extreme temperatures without melting, cracking, or reacting with your sample.

Porcelain, alumina, or quartz crucibles are common and appropriate choices for high-temperature work. Never place glass, plastic, or materials not rated for the target temperature inside the furnace.

Step 2: Power Down the Furnace

Before opening the door, disconnect the main power supply. Do not rely solely on the controller's off switch. This is a non-negotiable step to prevent electric shock.

Step 3: Position the Sample Carefully

Open the furnace door and use tongs to grip your crucible. Carefully place it in the center of the furnace floor.

If loading multiple samples, arrange them neatly in the center with space between them to allow for even heat circulation.

Step 4: Secure the Chamber

Once the sample is in place, close the furnace door and ensure it is latched securely. A poorly sealed door leads to heat loss and temperature instability, compromising your experiment.

Understanding the Trade-offs and Critical Components

Knowing why these rules exist empowers you to avoid common and costly mistakes.

The Thermocouple: The Furnace's Nerve Center

At the back of the furnace chamber, you will see a small ceramic rod or probe. This is the thermocouple, the sensor that measures the internal temperature.

Bumping or damaging the thermocouple can cause inaccurate temperature readings or complete furnace failure. Any contact can compromise the integrity of your current experiment and all future ones, making this the single most important component to avoid touching.

The "Hot Zone": Why Center Placement Matters

The heating elements in a muffle furnace are typically embedded in the walls. This creates a "hot zone" in the middle of the chamber where the temperature is most uniform.

Areas near the door are cooler due to inevitable heat loss, while areas directly against the walls can be hotter. Placing your sample anywhere but the center introduces a variable that can ruin the repeatability of your work.

The Risk of Thermal Shock

A common pitfall is placing a sample that is wet or contained in a compromised crucible into a hot furnace. The rapid temperature change can cause the moisture to turn to steam explosively or the crucible to crack. This is known as thermal shock.

Always ensure your sample and crucible are dry and at room temperature before placing them in a cold furnace to be heated gradually.

Applying This to Your Work

Your specific procedure is a balance between safety and precision. Use these points to guide your actions.

- If your primary focus is safety and equipment longevity: Always power down the furnace before loading and never, under any circumstance, touch the thermocouple at the back of the chamber.

- If your primary focus is analytical accuracy: Place your sample in the geometric center of the furnace to ensure it experiences the most uniform and stable heating environment.

- If your primary focus is preventing sample failure: Ensure your sample is contained in a dry, appropriate refractory crucible to avoid thermal shock and material degradation.

Mastering this fundamental procedure ensures safe operation and delivers reliable, repeatable results for your work.

Summary Table:

| Key Principle | Action Required |

|---|---|

| Safety First | Power down furnace, wear PPE, use long tongs. |

| Accuracy & Precision | Place sample in the geometric center of the chamber. |

| Container Selection | Use a dry, heat-resistant crucible (e.g., porcelain, alumina). |

| Critical Component | Avoid contact with the thermocouple at the back of the chamber. |

Achieve Perfect Results with Every Run

Proper sample handling is the foundation of reliable lab work. KINTEK specializes in providing the high-quality lab equipment and consumables—like durable muffle furnaces and the right crucibles for your application—that your laboratory needs for safe and accurate operations.

Let our experts help you select the ideal equipment for your specific processes. Contact our team today to discuss your requirements and ensure your experiments are built on a foundation of precision and safety.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between an oven and a muffle? Choose the Right Heating Tool for Your Lab

- What is a muffle furnace in the environment? Achieve Clean, Contaminant-Free Heating

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What are the safety precautions for a muffle furnace? A Guide to Preventing Burns, Fires, and Electrical Hazards

- What is the setting of the muffle furnace? A Step-by-Step Guide to Safe & Accurate Operation