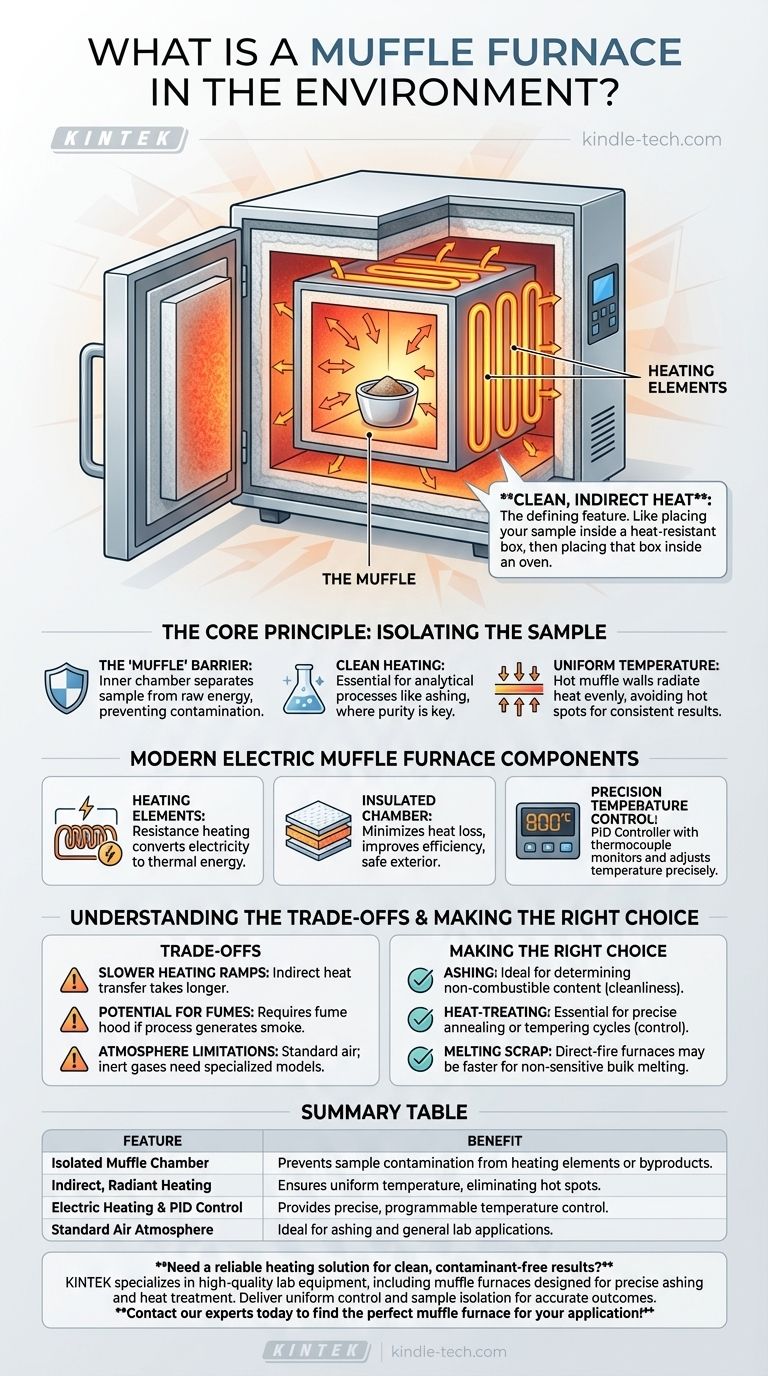

In essence, a muffle furnace is a high-temperature oven that uses an internal chamber—the "muffle"—to completely isolate the material being heated from the heating elements and any contaminants. This design ensures that the sample is heated uniformly in a clean, controlled environment, free from the byproducts of combustion or direct contact with the heat source.

The critical takeaway is that a muffle furnace's defining feature is not simply high heat, but clean, indirect heat. It functions like placing your sample inside a closed, heat-resistant box and then placing that box inside an oven, guaranteeing the sample is never touched by the fire or heating coils themselves.

The Core Principle: Isolating the Sample

A muffle furnace is defined by its method of heat transfer. Unlike a direct-fire kiln where flames make contact with the material, the muffle furnace relies on separation.

What is the "Muffle"?

The muffle is the inner chamber or box, typically made of high-temperature refractory ceramic. This container shields the contents from the raw energy source.

In ancient furnaces, this muffle protected objects from soot, ash, and gases from a wood or coal fire. In modern electric furnaces, it separates the workload from the glowing-hot heating coils.

How Isolation Achieves Clean Heating

By creating this barrier, the furnace prevents any contamination of the sample. This is critical for analytical processes like ashing, where the goal is to burn away organic material to measure the inorganic residue. Any external soot or particles would corrupt the results.

Ensuring Uniform Temperature

The heating elements heat the walls of the muffle chamber. These hot walls then radiate heat evenly from all sides onto the sample. This indirect heating method avoids "hot spots" that can occur with direct flame contact, leading to more consistent and predictable results.

How a Modern Electric Muffle Furnace Works

Today, most muffle furnaces are electric, offering precise control and operational simplicity. They are built around three primary components.

The Heating Elements

The furnace generates heat through resistance heating, also known as Joule heating. An electric current is passed through high-resistance coils (often made of materials like Nichrome or Kanthal), which convert electrical energy directly into thermal energy.

The Insulated Chamber

The heating elements are embedded within or wrapped around the external walls of the muffle chamber. This entire assembly is housed inside a heavily insulated cabinet, which minimizes heat loss, improves energy efficiency, and keeps the exterior safe to touch.

Precision Temperature Control

A temperature sensor, typically a thermocouple, is placed inside the chamber to monitor the internal temperature in real-time. This sensor feeds data to a PID controller (Proportional-Integral-Derivative), a sophisticated digital thermostat that precisely adjusts the power sent to the heating elements to maintain a stable setpoint or execute complex heating programs.

Understanding the Trade-offs

While powerful, muffle furnaces are not the solution for every high-temperature task. Understanding their limitations is key to using them effectively.

Slower Heating Ramps

Because the heat is transferred indirectly—from the elements, to the muffle walls, and then to the sample—heating times can be slower compared to a furnace where a flame directly impinges on the material.

Potential for Fume Generation

A standard muffle furnace heats a sample in ambient air. If the process generates smoke, fumes, or hazardous vapors (e.g., when burning off plastics), the furnace must be operated inside a fume hood. Some models include an exhaust port to help vent these fumes, but this does not replace the need for proper laboratory ventilation.

Atmosphere Limitations

Without modification, a muffle furnace provides a simple air atmosphere. For processes that require an inert environment (using argon or nitrogen) or a reactive one, specialized and more expensive models with sealed chambers and gas ports are necessary.

Making the Right Choice for Your Goal

Select your heating equipment based on the specific demands of your process.

- If your primary focus is determining the non-combustible content of a sample (ashing): A muffle furnace is the ideal tool, as its clean, indirect heating prevents contamination of the final residue.

- If your primary focus is heat-treating a metal part with precise temperature control: An electric muffle furnace with a programmable PID controller is essential for executing the required annealing or tempering cycles accurately.

- If your primary focus is simply melting a large quantity of non-sensitive scrap metal: A faster and potentially more energy-efficient direct-fire furnace, such as a crucible or reverberatory furnace, may be a better choice.

Ultimately, a muffle furnace is the definitive choice when process cleanliness and temperature uniformity are more important than raw heating speed.

Summary Table:

| Feature | Benefit |

|---|---|

| Isolated Muffle Chamber | Prevents sample contamination from heating elements or combustion byproducts. |

| Indirect, Radiant Heating | Ensures uniform temperature distribution, eliminating hot spots for consistent results. |

| Electric Heating & PID Control | Provides precise, programmable temperature control for complex processes. |

| Standard Air Atmosphere | Ideal for applications like ashing that do not require a specialized gas environment. |

Need a reliable heating solution that guarantees clean, contaminant-free results?

KINTEK specializes in high-quality lab equipment, including muffle furnaces designed for precise ashing, heat treatment, and more. Our furnaces deliver the uniform temperature control and sample isolation your laboratory requires for accurate, repeatable outcomes.

Contact our experts today to find the perfect muffle furnace for your specific application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between oven incubator and muffle furnace? Choose the Right Lab Heating Tool

- How accurate is the muffle furnace? Achieve ±1°C Control and ±2°C Uniformity

- What are the safety precautions during heat treatment process? A Guide to Mitigating Thermal, Atmospheric, and Mechanical Hazards

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage

- What is the difference between sintering and firing? A Guide to Thermal Process Terminology