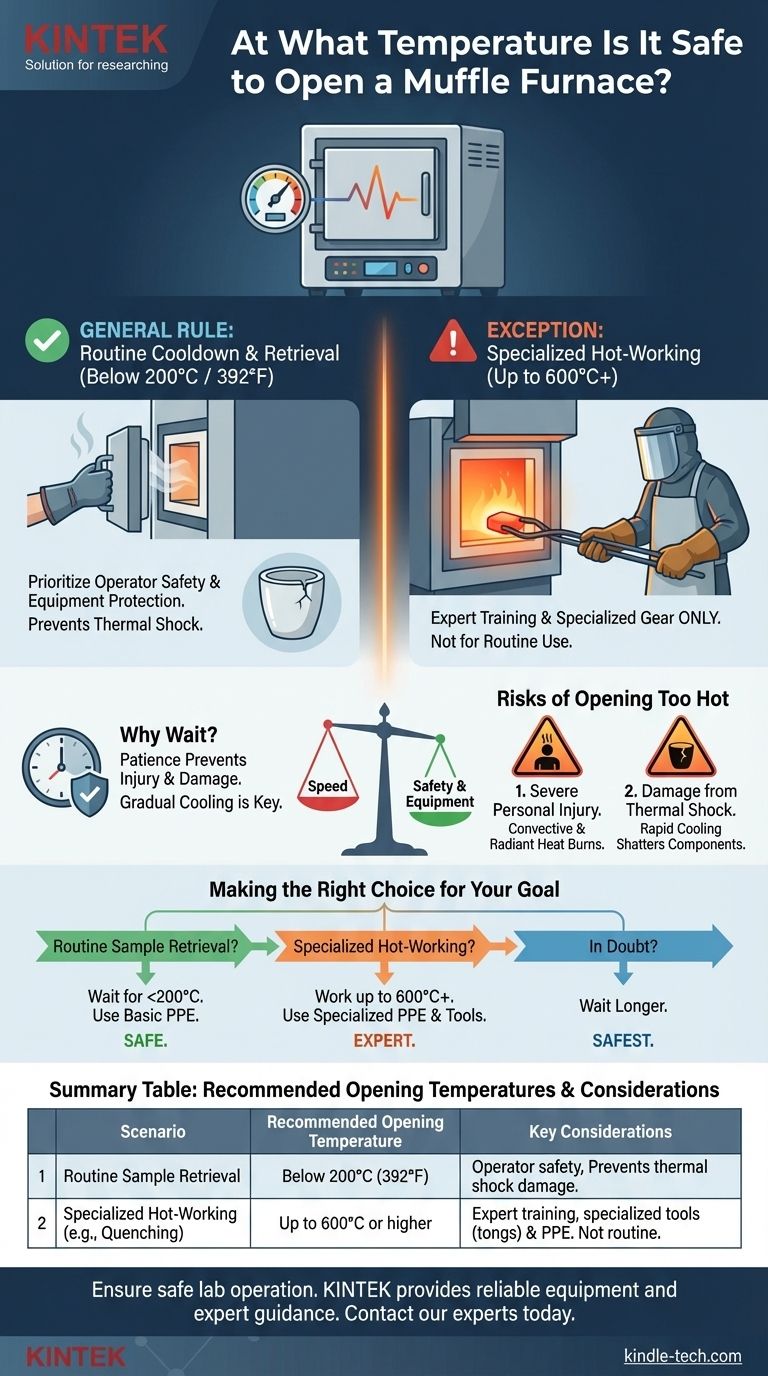

For general safety and equipment protection, you should wait for a muffle furnace to cool to below 200°C (392°F) before opening the door. While specialized, high-temperature procedures may require accessing the furnace at temperatures as high as 600°C, this is an exception for trained personnel with specific equipment and is not a standard practice for routine operation.

The "safe" opening temperature is not a single number but is dictated entirely by your task. Confusing the requirements for specialized hot-working with routine sample retrieval is a critical safety mistake. For most users, patience is paramount; waiting for the furnace to cool significantly prevents personal injury and equipment damage from thermal shock.

Why "Safe Temperature" Is Task-Dependent

The correct temperature to open a muffle furnace hinges on what you are trying to accomplish. The risks and requirements for handling a material at a specific process temperature are fundamentally different from simply retrieving a cooled sample.

The High-Temperature Exception: Hot-Working

Certain metallurgical or ceramic processes, like quenching or forging, require materials to be removed from the furnace while still extremely hot.

For these specific tasks, an operator might open the door when the furnace is at 600°C or even higher. This is an advanced procedure that absolutely requires specialized tools like long tongs, silicon carbide hearth plates to protect the furnace floor, and extensive Personal Protective Equipment (PPE), including full-face shields and high-temperature gloves.

The General Rule: Routine Cooldown and Retrieval

For all other standard applications, the primary goals are protecting the operator from extreme heat and preventing damage to the furnace or its contents.

Opening a furnace above 200°C creates significant safety risks and exposes the equipment to potential damage from thermal shock.

The Two Core Risks of Opening a Furnace Too Hot

Rushing to open a muffle furnace introduces two major hazards that a patient, methodical approach avoids entirely.

Risk 1: Severe Personal Injury

The moment the door is opened, a blast of superheated air is released. This convective heat can cause severe burns to unprotected skin and eyes instantly.

Furthermore, the radiant heat from the furnace walls and contents can be intense enough to cause serious injury even from a distance.

Risk 2: Damage from Thermal Shock

Thermal shock occurs when a material experiences rapid, uneven temperature change, causing it to crack or shatter.

When you open a hot furnace, cool ambient air rushes in. This can cause catastrophic failure of the ceramic insulation or crucibles inside, leading to expensive and time-consuming repairs. The same shock can also ruin the sample or material you were processing.

Understanding the Trade-offs

The only "benefit" of opening a furnace early is saving a small amount of time. This convenience is weighed against significant risks.

The Myth of Speed

In a professional or research environment, the time saved by premature opening is trivial compared to the potential cost of a failed process, a damaged furnace, or a safety incident.

The Value of Patience

Allowing the furnace to cool naturally under its own programmed ramp-down or a simple power-off ensures that the temperature change is gradual and uniform.

This protects the delicate ceramic components of the furnace and preserves the integrity of the materials inside. It is the foundation of repeatable, reliable thermal processing.

Making the Right Choice for Your Goal

Always assess your specific task and prioritize safety and equipment preservation above all else.

- If your primary focus is specialized hot-working (e.g., quenching steel): You will work at high temperatures dictated by your process, but this requires expert training and specialized safety and handling equipment.

- If your primary focus is general safety and retrieving a finished sample: You must wait for the furnace to cool to below 200°C, and always use appropriate PPE (heat-resistant gloves, face shield) even at this lower temperature.

- If you are ever in doubt about the temperature: The safest and most professional choice is to wait longer.

Prioritizing a deliberate and patient cooling process is the hallmark of safe and effective furnace operation.

Summary Table:

| Scenario | Recommended Opening Temperature | Key Considerations |

|---|---|---|

| Routine Sample Retrieval | Below 200°C (392°F) | Prioritizes operator safety and prevents equipment damage from thermal shock. |

| Specialized Hot-Working (e.g., Quenching) | Up to 600°C or higher | Requires expert training, specialized tools (long tongs), and extensive PPE. Not for routine use. |

Ensure your lab operates safely and efficiently. Rushing to open a muffle furnace can lead to severe personal injury and costly damage to sensitive components. At KINTEK, we specialize in providing reliable lab equipment and consumables, along with the expert guidance needed for safe operation. Protect your team and your investment—contact our experts today to find the right furnace and safety accessories for your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is ash content determination? Ensure Food Quality, Safety, and Compliance

- Why use a laboratory oven for drying before ICP-OES? Ensure Precise Elemental Analysis of Iron Oxides

- What role does a programmable muffle furnace play in studying the high-temperature performance of geopolymers?

- What is the function of a high-precision high-temperature furnace for 18 Ni (300) steel? Ensure Optimal Microstructure

- What role does a high-precision box furnace play in the torrefaction of sewage sludge? Optimize Your Carbonized Solid Fuel

- What is the necessity of a box-type furnace for UiO66-NH2-TiO2/NiF? Ensure High-Performance Composite Calcination

- What is the difference between oven and muffle furnace? A Guide to Choosing the Right Heating Equipment

- What is the annealing process in a furnace? Achieve Precise Material Softening and Stress Relief