To operate a hydraulic press, you first position your workpiece on the base plate and turn the leadscrew to bring the ram into light contact with it. You then use the pump handle or power system to force hydraulic fluid into the main cylinder, which drives the ram down and applies immense, controlled pressure onto the workpiece.

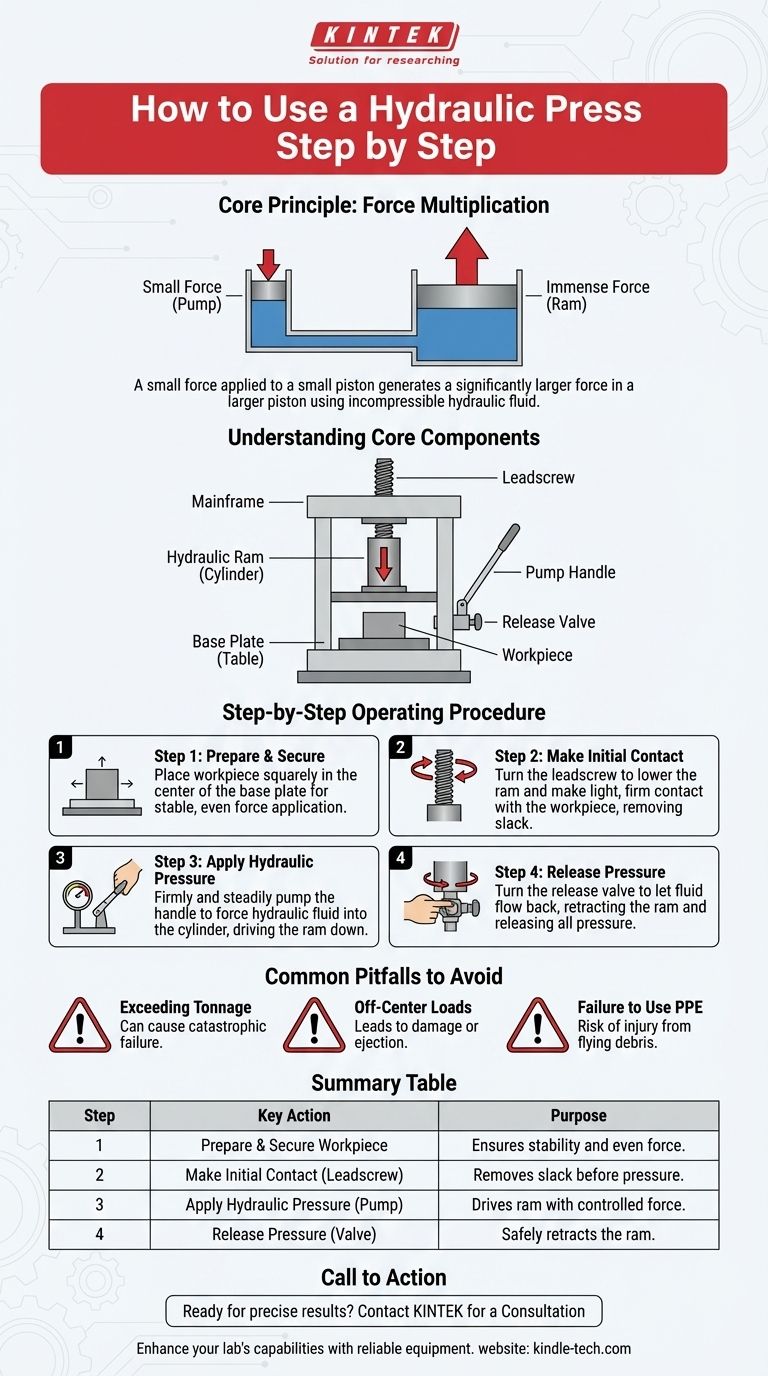

The core principle of a hydraulic press is force multiplication. By using an incompressible fluid like oil, a small force applied to a small piston generates a significantly larger and more powerful force in a larger piston, allowing you to shape, bend, or compress materials with precision.

Understanding the Core Components

To use a press effectively and safely, you must first understand its fundamental parts. Each component plays a critical role in generating and containing immense force.

The Frame and Work Surface

The mainframe is the heavy-duty structure that holds the entire assembly together, providing the strength to withstand the operational pressure.

The material you are pressing rests on a table, also known as a bolster or base plate. This flat, sturdy surface supports the workpiece against the downward force of the ram.

The Hydraulic Ram (The "Business End")

The hydraulic ram, or steel cylinder, is the large piston that moves downward to apply force. It is the part of the press that does the actual work of compressing or separating your material.

The Pumping Mechanism

Pressure is created by a pump that forces hydraulic fluid into the ram's cylinder. In manual presses, this is a hand-operated lever or handle.

In larger, industrial presses, a hydraulic power unit and directional control valves manage the flow of high-pressure oil, allowing for more precise and automated control.

The Role of Hydraulic Fluid

The system is filled with a specialized hydraulic fluid (typically oil). Because this fluid is nearly incompressible, it efficiently transfers pressure from the smaller pump piston to the much larger ram piston, multiplying the initial force.

The Step-by-Step Operating Procedure

While specific controls vary, the fundamental process for operating a manual hydraulic press follows a clear sequence.

Step 1: Prepare and Secure the Workpiece

Place the item you intend to press squarely in the center of the base plate or table. Ensuring the workpiece is stable and centered is critical for an even application of force.

Step 2: Make Initial Contact

Slowly turn the leadscrew at the top of the press. This will lower the ram assembly until its nose makes light, firm contact with the top of your workpiece. This step removes any slack before you begin applying hydraulic pressure.

Step 3: Apply Hydraulic Pressure

Begin pumping the handle firmly and steadily. With each pump, you are forcing hydraulic oil into the main cylinder, driving the ram down with increasing force. Continue pumping until you have applied the desired pressure or achieved the necessary compression.

Step 4: Release the Pressure

Once your task is complete, locate the release valve. Turning this valve allows the hydraulic fluid to flow back out of the cylinder, retracting the ram and releasing all pressure from the workpiece.

Common Pitfalls to Avoid

The immense power of a hydraulic press demands respect and a clear understanding of potential risks. Misuse can damage the equipment, the workpiece, and cause serious injury.

The Danger of Exceeding Tonnage

Every press has a maximum force rating (its tonnage). Attempting to exceed this limit can cause catastrophic failure of the frame or hydraulic components. Always be aware of the pressure you are applying.

The Risk of Off-Center Loads

Placing a workpiece off-center creates an uneven load on the ram and frame. This can lead to inaccurate pressing, damage to the ram, and in extreme cases, can cause the workpiece to be ejected from the press at high velocity.

Failure to Use Protective Equipment

Always wear appropriate Personal Protective Equipment (PPE), including safety glasses or a face shield. Materials can fracture or shatter unexpectedly under extreme pressure, sending shrapnel flying.

Making the Right Choice for Your Goal

Your operational focus should adapt to the specific task you are performing.

- If your primary focus is precision sample preparation: Concentrate on applying pressure slowly and gradually, watching the pressure gauge carefully to avoid over-compressing a delicate sample.

- If your primary focus is assembly or bearing removal: Ensure all components are perfectly aligned and square before applying force to prevent binding and damaging the parts.

- If your primary focus is heavy forming or bending metal: Double-check that the workpiece is perfectly centered and that the tonnage required is well within the press's rated capacity.

Understanding both the operational steps and the principles behind them is the key to using a hydraulic press safely and effectively.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Prepare & Secure Workpiece | Ensures stability and even force application. |

| 2 | Make Initial Contact (Leadscrew) | Removes slack before hydraulic pressure is applied. |

| 3 | Apply Hydraulic Pressure (Pump Handle) | Drives the ram down with controlled, immense force. |

| 4 | Release Pressure (Release Valve) | Safely retracts the ram and completes the operation. |

Ready to achieve precise and powerful results in your lab?

Operating a hydraulic press correctly is crucial for safety and accuracy in material testing, sample preparation, and assembly tasks. KINTEK specializes in providing robust and reliable lab equipment, including hydraulic presses, designed to meet the demanding needs of modern laboratories.

Our experts can help you select the perfect press for your specific applications, ensuring you have the right tool for precise force control. Contact us today to discuss your requirements and enhance your lab's capabilities.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis