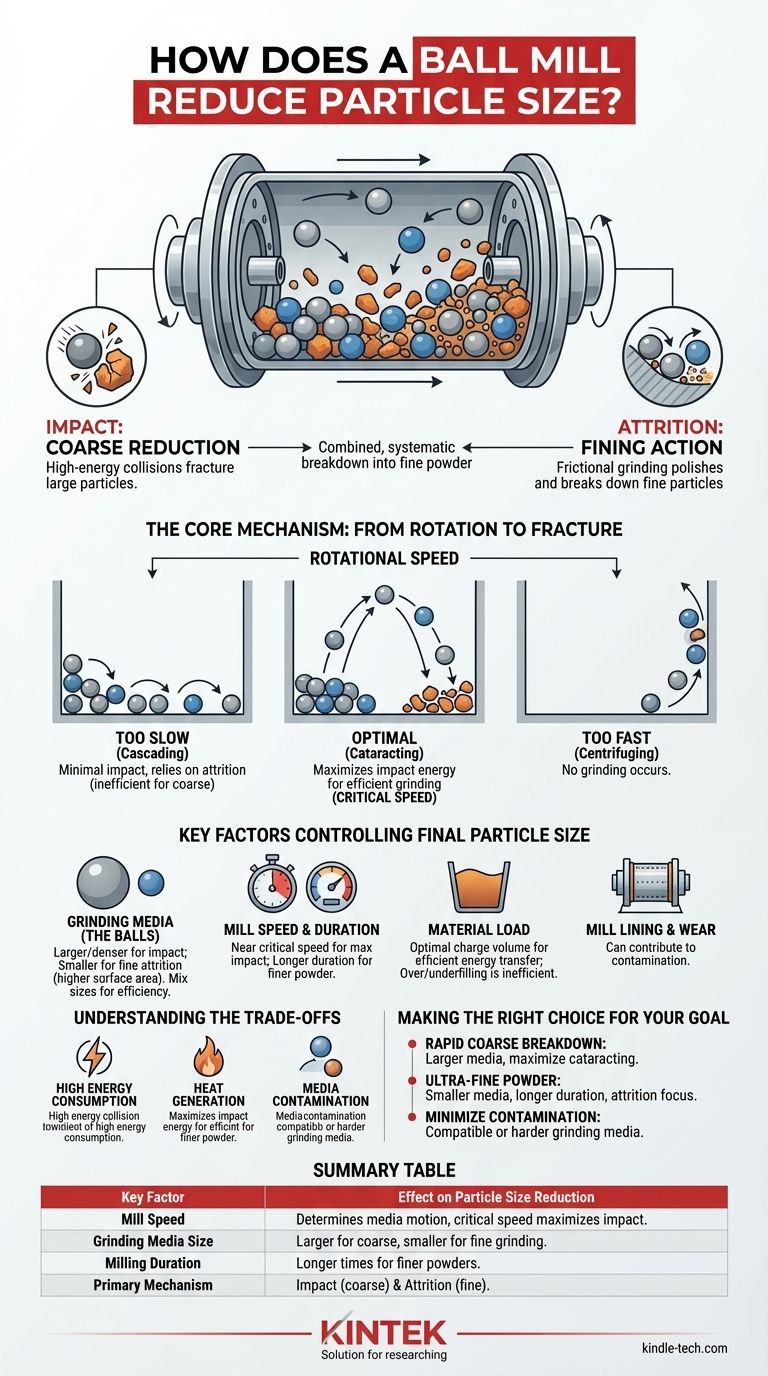

At its core, a ball mill reduces particle size by transferring kinetic energy. Inside a rotating cylindrical chamber, a set of grinding media—typically steel or ceramic balls—are lifted on the rising side of the chamber and then fall onto the material being processed. This repeated, high-energy impact, combined with the grinding action from balls rubbing against each other, systematically breaks down coarse particles into a fine powder.

A ball mill operates on a simple principle: converting the rotational energy of a cylinder into the kinetic energy of internal grinding media. This energy then fractures material through two key actions: high-impact collisions and frictional grinding.

The Core Mechanism: From Rotation to Fracture

To truly understand a ball mill, you must visualize the journey of the material and the media inside the rotating drum. The process is not random tumbling; it is a controlled application of mechanical force.

The Role of Rotational Speed

The speed of the mill's rotation is the most critical operational parameter. It dictates how the grinding media behaves.

If the mill rotates too slowly, the balls will simply roll down the face of the other balls in a process called cascading. This results in minimal impact and primarily relies on attrition, which is inefficient for breaking larger particles.

If the mill rotates too quickly, centrifugal force will pin the balls to the inner wall of the chamber. This is known as centrifuging, and no grinding occurs because the balls never fall.

The optimal speed, often called the critical speed, allows the balls to be carried almost to the top of the chamber before breaking contact and falling freely. This creates a cataracting motion, maximizing impact energy.

Impact: The Primary Force

The primary mechanism for coarse size reduction is impact. As the mill rotates, the grinding balls are lifted and then drop from a significant height, striking the material below with tremendous force.

This action is similar to repeatedly striking a rock with a hammer. These high-energy impacts are what cause the initial fractures in large, coarse feed materials.

Attrition: The Fining Action

The secondary mechanism, which is crucial for producing very fine powders, is attrition. This is the grinding that occurs as balls slide, tumble, and roll against each other and the inner wall of the mill.

As particles are caught between these moving surfaces, they are subjected to intense shear and compressive forces. This frictional grinding polishes and breaks down already small particles into a much finer state.

Key Factors Controlling Final Particle Size

The final particle size is not an accident; it is the result of several controllable variables. Mastering these factors allows you to tailor the output to your specific needs.

The Grinding Media (The Balls)

The characteristics of the balls themselves are paramount. Larger, denser balls deliver higher impact forces and are more effective at breaking down coarse feed.

Smaller balls, in contrast, have a much higher surface area for a given volume. They are more effective at fine grinding through attrition because they increase the number of contact points and reduce the empty space (voids) between balls. A common strategy is to use a mix of sizes for efficient grinding across a range of particle sizes.

Mill Speed and Duration

As noted, operating near the critical speed ensures maximum impact efficiency. Beyond the speed itself, the duration of the milling process is a straightforward control factor. The longer the material is milled, the finer the resulting powder will be, up to a certain physical limit.

Material Load

The amount of material loaded into the mill relative to the amount of grinding media (the "charge volume") is also important. Overfilling the mill will cushion the ball impacts and reduce grinding efficiency, while underfilling it can lead to inefficient energy transfer and increased wear on the mill lining.

Understanding the Trade-offs

While powerful, ball milling is not without its limitations. An objective assessment requires acknowledging these practical realities.

High Energy Consumption

Ball mills are energy-intensive machines. A significant amount of electrical energy is required to rotate the heavy drum and its contents, much of which is converted into sound and heat rather than useful grinding work.

Heat Generation

The constant friction and impact generate substantial heat. For heat-sensitive materials, such as certain polymers or organic compounds, this can be a major problem, potentially causing melting, degradation, or chemical changes.

Media Contamination

The grinding process inevitably causes wear on the grinding media and the mill's inner lining. This worn material can contaminate the final product. While minimal, this can be a critical issue in high-purity applications like pharmaceuticals, food products, or advanced ceramics.

Making the Right Choice for Your Goal

By adjusting the key parameters, you can optimize the ball milling process for a specific outcome.

- If your primary focus is rapid breakdown of coarse material: Use a charge of larger, high-density grinding media and operate at a speed that maximizes cataracting and impact forces.

- If your primary focus is producing an ultra-fine powder: Use a higher volume of smaller grinding media to maximize surface area and promote grinding by attrition over a longer milling time.

- If your primary focus is minimizing product contamination: Select grinding media made of a material that is compatible with your product or significantly harder than it (e.g., using zirconia or alumina balls for grinding ceramic powders).

By understanding these core principles, you can effectively control the ball milling process to achieve your precise particle size requirements.

Summary Table:

| Key Factor | Effect on Particle Size Reduction |

|---|---|

| Mill Speed | Determines grinding media motion (cascading, cataracting, centrifuging). Critical speed maximizes impact. |

| Grinding Media Size | Larger balls for coarse crushing; smaller balls for fine grinding via increased surface area. |

| Milling Duration | Longer milling times generally produce finer powders, up to a physical limit. |

| Primary Mechanism | Impact (for coarse reduction) and Attrition (for fine grinding). |

Ready to achieve precise particle size reduction in your lab? KINTEK specializes in high-quality lab equipment, including ball mills and grinding media, to meet your specific research and production needs. Our experts can help you select the ideal setup for efficient and contamination-free milling. Contact us today to optimize your process!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Powerful Plastic Crusher Machine

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- What is the difference between a ball mill and an attritor? Choose the Right Mill for Your Particle Size Goals

- What are the steps in ball milling? A Guide to Effective Particle Size Reduction

- What is the capacity of a ball mill? Optimize Your Grinding Process for Maximum Efficiency

- What is the working capacity of a ball mill? Optimize Volume, Speed, and Grinding Media for Maximum Output

- What are the disadvantages of a ball mill? Key Limitations for Your Grinding Process