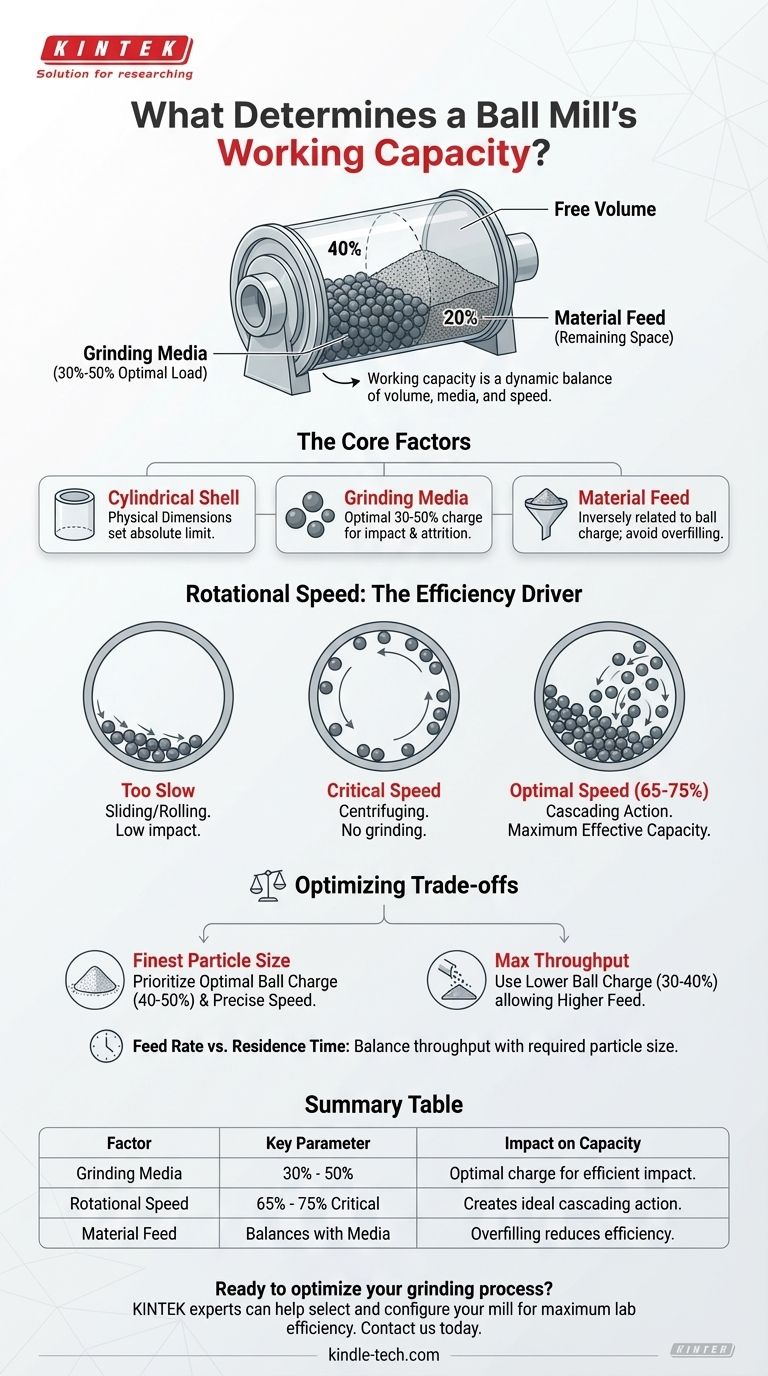

In simple terms, a ball mill's working capacity is determined by the volume of grinding media (the balls) inside it. The standard and most effective load for these balls is between 30% and 50% of the total internal volume of the mill's cylindrical shell. This leaves the remaining space for the material you intend to grind.

The true capacity of a ball mill is not a single number but a dynamic balance. It depends on the physical volume of the mill, the charge of grinding media, and the rotational speed, all of which must be optimized to achieve efficient size reduction.

The Core Factors Defining Capacity

To understand a ball mill's effective throughput, you must first understand its fundamental components and how they interact. The physical dimensions set the absolute limit, but the operational parameters determine the actual output.

The Cylindrical Shell

The starting point for capacity is the physical size of the mill's hollow cylinder. Its diameter and length dictate the maximum volume of both grinding media and material that can be loaded.

The shell is typically lined with an abrasion-resistant material, such as manganese steel, which slightly reduces the internal volume but is critical for the mill's longevity.

The Grinding Media (Balls)

The volume of the grinding balls is the most critical factor in defining the working capacity. The 30% to 50% rule is the industry standard for optimal performance.

This specific range ensures there are enough balls to create sufficient impact and attrition for effective grinding, while still leaving adequate space for the material to be processed.

The Material Feed

The amount of raw material you can add is inversely related to the ball charge. If the balls take up 40% of the volume, the material feed can only occupy a portion of the remaining 60%.

Overfilling the mill with material will cushion the balls' impacts, drastically reducing grinding efficiency and lowering the effective capacity.

How Rotational Speed Dictates Efficiency

A mill's physical volume is meaningless if it isn't operated correctly. The rotational speed directly controls the grinding action and, therefore, the mill's actual throughput. The key concept here is critical speed.

What is Critical Speed?

Critical speed is the theoretical speed at which the grinding balls are pinned against the inner wall of the shell by centrifugal force. At this speed, they stop tumbling and cascading, and grinding ceases.

The Problem with Incorrect Speeds

If the mill runs too slowly, the balls will simply slide or roll at the bottom, failing to create the necessary impact to break down the material.

If the mill runs at or above critical speed, the balls centrifuge and are carried around with the shell, again resulting in little to no grinding.

The Optimal Speed for Grinding

Effective grinding happens when the mill operates at a specific percentage of its critical speed, typically between 65% and 75%.

At this optimal speed, the balls are carried up the side of the shell and then cascade and tumble down, creating the powerful impact and attrition forces that grind the material. This is where the mill achieves its maximum effective capacity.

Understanding the Trade-offs

Optimizing a ball mill requires balancing competing factors. A change in one variable can negatively impact another, so it's crucial to understand the compromises.

Overfilling with Grinding Media (>50%)

Loading the mill with too many balls might seem like it would increase grinding, but it has the opposite effect. It restricts the movement of the balls, reduces the space available for the material, and ultimately lowers grinding efficiency.

Underfilling with Grinding Media (<30%)

Using too few balls means there are not enough impact points to grind the material efficiently. This results in significantly longer processing times and reduces the overall throughput of the mill.

Feed Rate vs. Residence Time

A higher feed rate increases the amount of material entering the mill, but it also reduces the time the material spends being ground. This can lead to a coarser final product. You must balance throughput goals with the required particle size.

Making the Right Choice for Your Goal

Achieving your desired output requires aligning the mill's operating parameters with your primary objective.

- If your primary focus is achieving the finest possible particle size: Prioritize an optimal ball charge (around 40-50%) and a precise rotational speed to maximize impact energy and grinding time.

- If your primary focus is maximizing material throughput: Use a slightly lower ball charge (around 30-40%) to allow for a higher material feed, while ensuring the speed is still in the optimal range for efficient, if not perfect, grinding.

Ultimately, a ball mill's capacity is a direct result of the controlled, violent interaction between the grinding media and the material, all governed by rotational physics.

Summary Table:

| Factor | Key Parameter | Impact on Capacity |

|---|---|---|

| Grinding Media | 30% - 50% of mill volume | Optimal charge ensures efficient impact and attrition |

| Rotational Speed | 65% - 75% of critical speed | Creates the ideal cascading action for grinding |

| Material Feed | Balances with ball charge | Overfilling reduces efficiency; underfilling lowers throughput |

Ready to optimize your grinding process? The experts at KINTEK can help you select the perfect ball mill and configure its operational parameters to maximize your lab's efficiency and throughput. Contact us today to discuss your specific laboratory needs and discover our range of high-performance lab equipment and consumables.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency