In simple terms, a hydraulic press works by using an incompressible fluid, like oil, to multiply force. A small amount of force is applied to a small piston, which creates pressure in the fluid. This pressure is then transmitted to a much larger piston, which generates a significantly larger output force capable of shaping, crushing, or forging materials.

The core principle is not about creating energy, but about trading distance for force. By applying a constant pressure over two different-sized areas, a hydraulic press multiplies a small input effort into an immensely powerful output, governed by a fundamental law of physics.

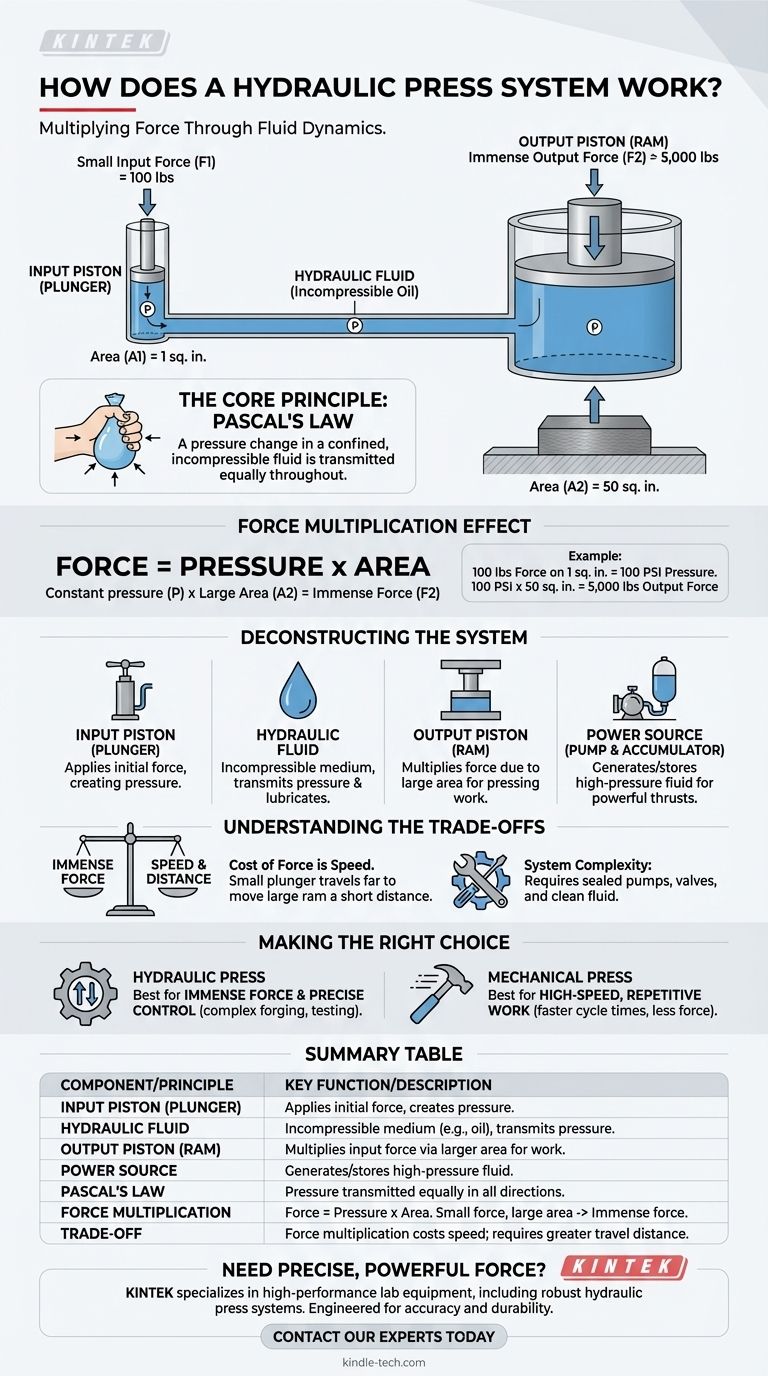

The Core Principle: Pascal's Law Explained

A hydraulic press is a direct application of one of the most fundamental principles in fluid mechanics: Pascal's Law. Understanding this concept is key to understanding the entire system.

What is Pascal's Law?

Pascal's Law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally throughout the fluid in all directions.

Think of it like squeezing a sealed water balloon. The pressure you apply with your fingers is felt equally on every other part of the balloon's inner surface.

In a hydraulic press, the "balloon" is a sealed system of cylinders and pipes filled with hydraulic oil.

The Force Multiplication Effect

This is where the true power of the system is unlocked. The formula that matters is Force = Pressure x Area.

Since Pascal's Law guarantees the pressure is constant throughout the fluid, we can use two pistons with different areas to multiply force.

Imagine applying 100 pounds of force to a small input piston (a plunger) with an area of 1 square inch. This generates 100 pounds per square inch (PSI) of pressure in the fluid.

That same 100 PSI of pressure then pushes against a large output piston (a ram) with an area of 50 square inches. The resulting output force is 100 PSI x 50 sq. inches, which equals 5,000 pounds of force.

Deconstructing the Hydraulic Press System

While the principle is simple, a functional press relies on several key components working together to generate and control this immense force.

The Input Piston (Plunger)

This is the smaller piston where the initial force is applied. In many systems, this force is generated by a hydraulic pump, which continuously pushes fluid into the system to build pressure.

The Hydraulic Fluid (The Medium)

Oil is the most common fluid used. It is chosen because it is practically incompressible, meaning it won't squash under pressure and efficiently transfers energy from one piston to the other. It also lubricates the system's moving parts.

The Output Piston (Ram)

This is the larger piston that receives the transmitted pressure from the fluid. Because of its large surface area, it multiplies the initial force and performs the actual work of pressing, forging, or crushing the object placed beneath it.

The Power Source (Pump & Accumulator)

A high-pressure pump is the heart of the system, supplying the pressurized liquid. Sometimes, this is paired with a hydraulic accumulator, a device that stores this high-pressure fluid.

The accumulator acts like a capacitor in an electrical circuit, allowing the system to release a massive amount of stored energy very quickly when a strong, sudden thrust is needed.

Understanding the Trade-offs

The immense force generated by a hydraulic press is not without its compromises. It is crucial to understand the inherent limitations of the design.

The Cost of Force is Speed

There is no free lunch in physics. The trade-off for multiplying force is the distance the pistons must travel.

To move the large ram by just one inch, the small plunger must travel a significantly greater distance. This is why hydraulic presses are incredibly powerful but often much slower than their mechanical counterparts.

System Complexity and Maintenance

Hydraulic systems involve high-pressure pumps, reinforced hoses, precision valves, and critical seals to contain the fluid.

Any leak in the system can lead to a loss of pressure and performance. The hydraulic fluid must also be kept clean and replaced periodically to prevent damage to the components.

Unmatched Control and Precision

Despite their relative slowness, a key advantage of hydraulic systems is their exceptional control.

Operators can precisely manage the force, speed, and position of the ram throughout the entire pressing process. This makes them ideal for complex forging operations where specific geometries and material properties are required.

Making the Right Choice for Your Application

Understanding the principles of a hydraulic press allows you to recognize when its unique characteristics are the ideal solution for a specific task.

- If your primary focus is generating immense force: The force multiplication principle makes hydraulics the go-to choice for applications requiring massive tonnage in a relatively compact machine.

- If your primary focus is precise control over the work: The ability to finely tune pressure and speed makes a hydraulic press ideal for delicate or complex forging, molding, and assembly tasks.

- If your primary focus is high-speed, repetitive work: A mechanical press is often a better choice, as it sacrifices force control for much faster cycle times.

By mastering the relationship between pressure, area, and fluid, the hydraulic press transforms a small input into a force capable of shaping the modern world.

Summary Table:

| Component | Key Function |

|---|---|

| Input Piston (Plunger) | Applies initial force, often via a pump, to create system pressure. |

| Hydraulic Fluid | Incompressible medium (like oil) that transmits pressure throughout the system. |

| Output Piston (Ram) | Multiplies the input force due to its larger area to perform the pressing work. |

| Power Source (Pump/Accumulator) | Generates and can store high-pressure fluid for powerful, controlled thrusts. |

| Key Principle | Pascal's Law: Pressure applied to a confined fluid is transmitted equally in all directions. |

| Force Multiplication | Force = Pressure × Area. A small force on a small area creates pressure, which acts on a large area to generate immense force. |

| Trade-off | Force multiplication comes at the cost of speed; the input piston must travel a greater distance. |

Need precise, powerful force for your lab or production line?

KINTEK specializes in high-performance lab equipment, including robust hydraulic press systems. Whether your application requires immense tonnage for material testing, precise control for sample preparation, or reliable forging capabilities, our solutions are engineered for accuracy and durability.

Let us help you harness the power of hydraulics. Contact our experts today to find the perfect press for your specific laboratory or industrial needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the specific application of a laboratory hydraulic press in LNMO cathode fabrication? Enhance Density & Performance

- What is the role of a laboratory hydraulic press in LLZO pellet preparation? Enhance Ionic Conductivity via Cold Pressing

- Is KBr used in IR spectroscopy? The Essential Guide to Solid Sample Analysis

- How is a hydraulic press so strong? Unlocking the Power of Force Multiplication

- Why are hydraulic presses and pressure dies used for composite electrodes? Optimize Solid-State Battery Conductivity

- Why is a powder hydraulic press used to create reaction pellets during the carbothermic reduction of magnesium?

- What is the BARS apparatus and what is its basic structure? Discover Compact High-Pressure Diamond Synthesis

- What is the system of a hydraulic press? Harnessing Pascal's Law for Immense Force