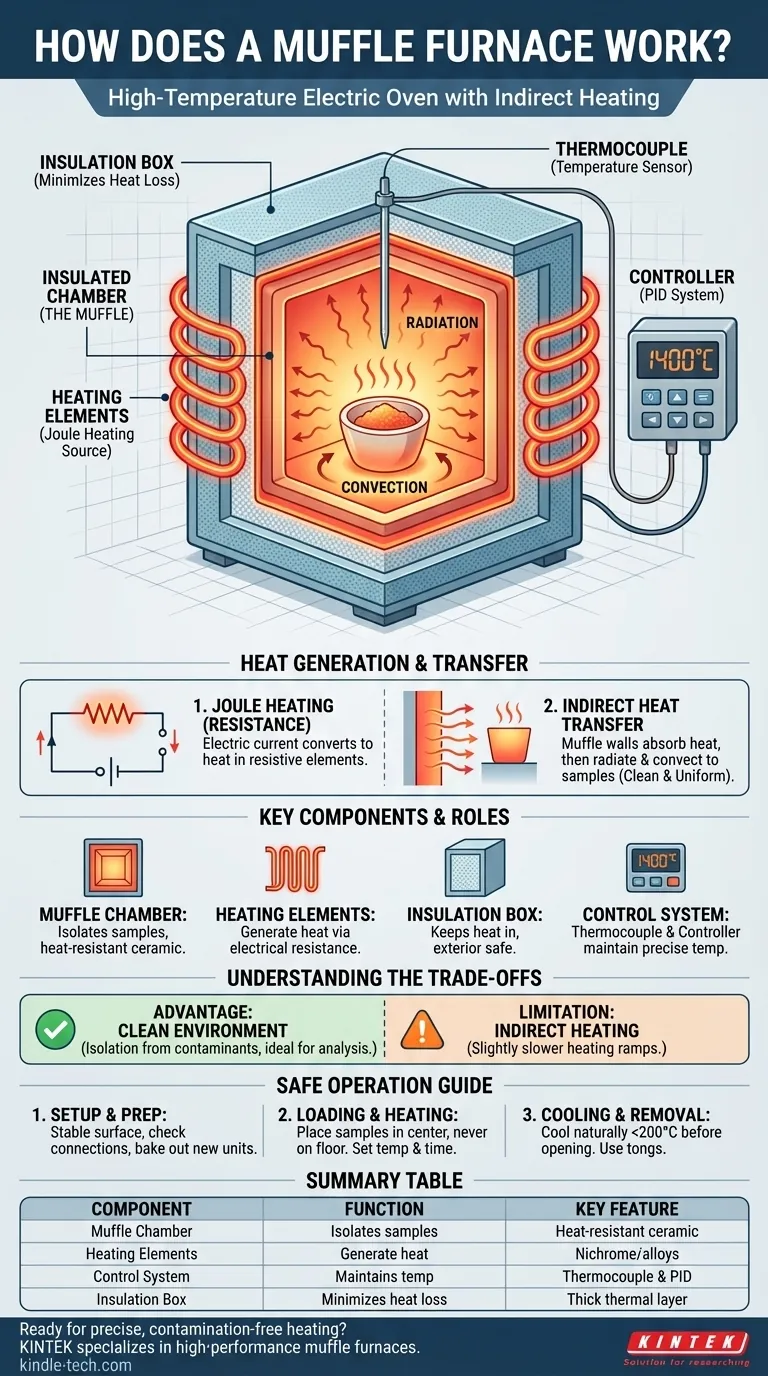

At its core, a muffle furnace is a high-temperature electric oven that uses a shielded heating chamber. It is engineered to heat materials to precise temperatures, often up to 1400°C, while isolating them from direct contact with the heating elements and any contaminants. This process relies on converting electrical energy into intense, controlled heat within a well-insulated box.

The furnace's defining principle is indirect heating. Electrical elements heat a sealed chamber (the "muffle"), which then transfers heat to the contents via radiation and convection, ensuring a clean and uniform thermal environment.

How a Muffle Furnace Generates Heat

A muffle furnace's operation is based on a straightforward principle of energy conversion, executed with precision components to achieve high temperatures.

The Principle of Resistance Heating

The furnace's heat source is Joule heating, also known as resistance heating. An electric current is passed through specialized heating elements.

These elements, often made of materials like nichrome or other alloys, have high electrical resistance. As the current struggles to pass through, it forces the electrical energy to convert directly into heat energy.

Heat Transfer Within the Chamber

The generated heat is not applied directly to the samples. Instead, the heating elements radiate heat to the inner walls of the furnace's chamber.

The chamber walls absorb this energy and, in turn, heat the atmosphere and the samples inside through a combination of radiation and convection. This indirect method prevents contamination and ensures more uniform temperature distribution.

The Key Components and Their Roles

A muffle furnace is a system of parts working together to create a controlled heating environment. Understanding each part clarifies the entire process.

The Insulated Chamber (The Muffle)

This is the heart of the furnace. It is a sealed chamber typically made of a heat-resistant ceramic material. This ceramic "muffle" is what isolates the workload from the heating elements.

Its refractory properties allow it to withstand extreme temperatures without degrading and prevent heat from escaping into the furnace's external structure.

The Heating Elements

These are the conductors that generate heat. They are strategically placed around the outside of the muffle chamber to provide even heating.

The Insulation Box

Surrounding the muffle and its heating elements is a thick layer of thermal insulation. This material minimizes heat loss, allowing the furnace to reach and maintain high temperatures efficiently and keeping the exterior casing safe to touch.

The Temperature Control System

This is the furnace's brain. It consists of two primary parts:

- A thermocouple, which is a temperature sensor that extends into the heating chamber to measure the internal temperature in real-time.

- A controller (often a PID controller), which is a microprocessor that compares the thermocouple's reading to the user-defined setpoint temperature.

The controller then precisely adjusts the power sent to the heating elements to either raise, lower, or maintain the target temperature, creating a continuous feedback loop.

Understanding the Trade-offs

While highly effective, the design of a muffle furnace presents specific advantages and limitations that are important to recognize.

The "Muffle" Advantage: A Clean Environment

The primary benefit is isolation. Because the material is heated indirectly and is not exposed to any flame, fuel, or combustion byproducts, the heating process is exceptionally clean.

This is critical for applications like chemical analysis, ashing organic matter, or treating sensitive materials where contamination would invalidate the results.

The Limitation: Indirect Heating

The trade-off for this clean environment is that heat transfer is less direct than in other furnace types. This can result in slightly slower heating ramps compared to a furnace where a flame or the elements are in direct contact with the workload.

However, for most laboratory and research applications, the uniformity and purity of the heating process far outweigh a minor difference in heating speed.

A Step-by-Step Guide to Safe Operation

Proper use is essential for accurate results and for ensuring the longevity of the furnace.

Initial Setup and Preparation

Before use, ensure the furnace is on a stable, level surface and that the controller is not too close to the furnace body to prevent overheating. Connect the thermocouple and ensure all wiring is secure and properly grounded.

For a new furnace or one that has been unused for a long time, it is wise to run an empty heating cycle to bake out any moisture or impurities.

Loading and Heating Samples

Place your samples, often in ceramic crucibles, in the center of the chamber. Never place samples directly on the furnace floor or touching the heating elements, as this creates a fire risk and can damage the equipment.

Close the door, set your target temperature and time on the controller, and begin the heating cycle. Keep the door closed to prevent heat loss and thermal shock from cold air.

Cooling and Sample Removal

Once the heating cycle is complete, turn off the furnace power. Do not open the door immediately. Allow the furnace to cool down naturally to a safe temperature (typically below 200°C) before opening the door and carefully removing your samples with tongs.

Making the Right Choice for Your Goal

Your application dictates how you should view the furnace's capabilities.

- If your primary focus is material testing or heat treatment: Understand that the furnace provides a clean, controlled, and uniform heating environment, which is crucial for achieving reproducible results.

- If your primary focus is ashing or gravimetric analysis: Value the isolation from combustion byproducts, as this ensures that any measured weight change is due solely to the sample's reaction to heat.

- If your primary focus is safety and equipment longevity: Always follow a gradual heating and cooling protocol, and never place samples in direct contact with the furnace chamber floor.

By understanding these principles, you can operate a muffle furnace not just as a tool, but as a precision instrument for your specific application.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Insulated Chamber (Muffle) | Isolates samples from heating elements | Made of heat-resistant ceramic |

| Heating Elements | Generate heat via electrical resistance | Often made of nichrome or alloys |

| Temperature Control System | Maintains precise temperature setpoint | Uses thermocouple and PID controller |

| Insulation Box | Minimizes heat loss and ensures safety | Thick layer of thermal insulation |

Ready to achieve precise, contamination-free heating in your lab? KINTEK specializes in high-performance muffle furnaces and lab equipment designed for accuracy and durability. Whether you're conducting material testing, ashing, or heat treatment, our solutions ensure reliable results. Contact our experts today to find the perfect furnace for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does a high-temperature furnace maintain accuracy in biomass liquefaction? Explore Precise Thermal Stability

- Why are high-temperature carbonization furnaces and activation essential for supercapacitor activated carbon?

- What is the primary function of a high-temperature box resistance furnace when studying the thermal stability of expanded austenite?

- How does a muffle furnace ensure reliability in calcification roasting? Achieve Precision in Pellets Conversion

- What is a sintering furnace? A Guide to High-Temperature Materials Processing

- What function does a high-temperature annealing furnace serve in tungsten oxide post-processing? Key Phase Control

- What is muffle in muffle furnace? The Key to Contamination-Free High-Temperature Processing

- What is the role of a laboratory drying oven in HPS catalyst preparation? Optimize Your Impregnation Process