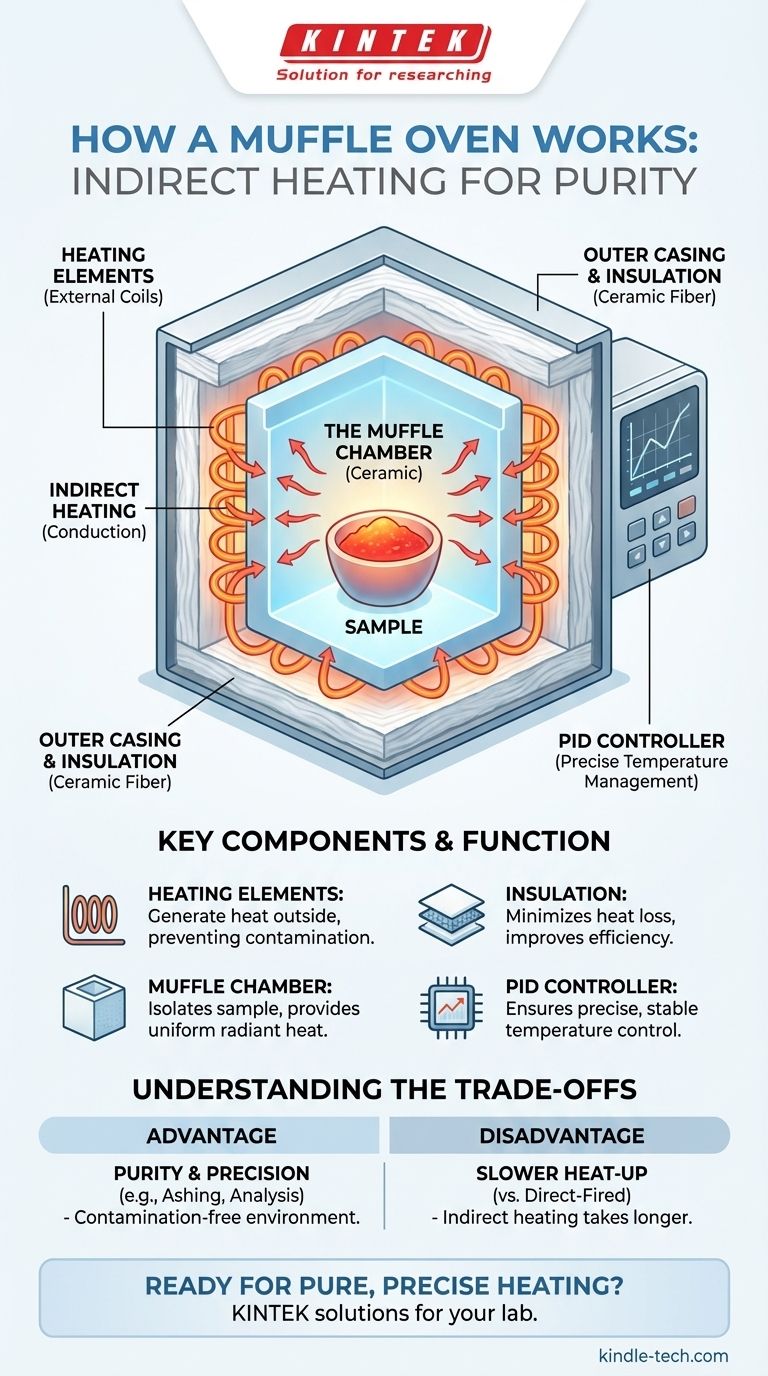

At its core, a muffle oven works by indirect heating. It uses a dedicated, insulated chamber—the "muffle"—to isolate the material being heated from the actual heating elements. This design prevents contamination from combustion byproducts or direct contact with the heat source, ensuring a clean and highly controlled thermal environment.

The defining characteristic of a muffle oven is not simply its ability to reach high temperatures, but its function as an isolation furnace. Its entire design is centered on providing uniform, pure heat by shielding the sample from the source of that heat.

The Core Principle: Heating Through Isolation

The name "muffle" refers to the central concept of muffling or shielding the sample. Unlike a simple oven where a flame or glowing element is in the same chamber as the item being heated, a muffle furnace creates a barrier.

What is the "Muffle"?

The muffle is the inner chamber of the furnace. It is typically a box made from high-temperature ceramic or other refractory materials that can withstand extreme thermal stress. This chamber is what holds your sample or crucible.

How Heat is Generated and Transferred

Modern muffle ovens are electrically powered. Heating coils are wrapped around the outside of the muffle chamber.

When the oven is turned on, these coils get extremely hot. They heat the walls of the muffle chamber through conduction. The hot chamber walls then radiate this thermal energy uniformly and evenly into the interior, heating the sample inside.

Key Components and Their Function

A muffle oven is a system where each part serves a critical purpose in achieving high-purity, high-temperature heating.

The Heating Elements

These are high-resistance electrical coils that generate intense heat when current passes through them. Their placement outside the muffle is the key to the oven's design.

The Insulated Muffle Chamber

This ceramic box serves two roles: it contains the sample and acts as the medium for transferring clean, radiant heat. Its material is chosen for extreme temperature resistance and thermal stability.

The Outer Casing and Insulation

Multiple layers of high-grade, fibrous ceramic insulation fill the space between the muffle and the furnace's exterior steel casing. This insulation minimizes heat loss, improves energy efficiency, and keeps the outer surfaces at a safe temperature.

The Digital Temperature Controller

Modern muffle furnaces use sophisticated controllers, often employing a PID (Proportional-Integral-Derivative) algorithm. This acts as the furnace's brain, precisely managing temperature by cycling power to the heating elements. It's especially effective for systems with high thermal inertia (slow to heat and cool), ensuring the temperature doesn't overshoot the target and can be held steady for long periods.

Understanding the Trade-offs

The unique design of a muffle oven offers distinct advantages but also comes with considerations you must understand.

Advantage: Purity and Precision

The primary benefit is preventing contamination. In applications like ashing organic compounds, gravimetric analysis, or material science research, any residue from a fuel source would ruin the results. The muffle design guarantees the only thing affecting the sample is heat.

Disadvantage: Slower Heat-Up Times

Because the heat transfer is indirect (coils heat the chamber, which then heats the sample), muffle furnaces can take longer to reach their target temperature compared to direct-fired furnaces. This is a trade-off for the gain in purity and uniformity.

Consideration: Atmosphere

A standard muffle oven operates in the ambient air atmosphere. While it prevents contamination from the heat source, the sample is still exposed to oxygen. For processes that require an inert atmosphere (like nitrogen or argon), a specialized tube furnace or vacuum oven is necessary.

Making the Right Choice for Your Goal

Selecting or using a muffle oven comes down to understanding why its specific design is necessary for your task.

- If your primary focus is analytical purity: A muffle oven is non-negotiable for applications like ashing, where you must ensure the final weight is free of any outside contaminants.

- If your primary focus is precise thermal processing: The combination of radiant heating and PID control provides the stable, uniform environment needed for treating sensitive materials.

- If your primary focus is simply reaching a high temperature: A muffle furnace is an excellent tool, but know that its design prioritizes control and purity over raw heating speed.

By understanding its principle of isolated heating, you can effectively leverage a muffle oven to achieve highly reliable and repeatable results.

Summary Table:

| Component | Function |

|---|---|

| Muffle Chamber | Ceramic inner box that isolates the sample and provides radiant heat. |

| Heating Elements | Coils outside the muffle that generate heat, preventing contamination. |

| Insulation | Layers of ceramic material that minimize heat loss and improve efficiency. |

| PID Controller | Manages power to the elements for precise, stable temperature control. |

Ready to achieve pure, contamination-free heating in your lab?

KINTEK specializes in high-performance muffle furnaces and lab equipment designed for applications where precision and sample purity are critical, such as ashing, gravimetric analysis, and material heat treatment. Our solutions provide the uniform, controlled thermal environment your research demands.

Contact our experts today to find the perfect muffle oven for your specific laboratory needs and ensure reliable, repeatable results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is the melting point different for different substances? The Key Role of Bond Strength

- At what temperature does quartz soften? Understand the practical limits for lab equipment

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- How to cool a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- What controls melting point? The Hierarchy of Forces from Ionic Bonds to Intermolecular Attractions