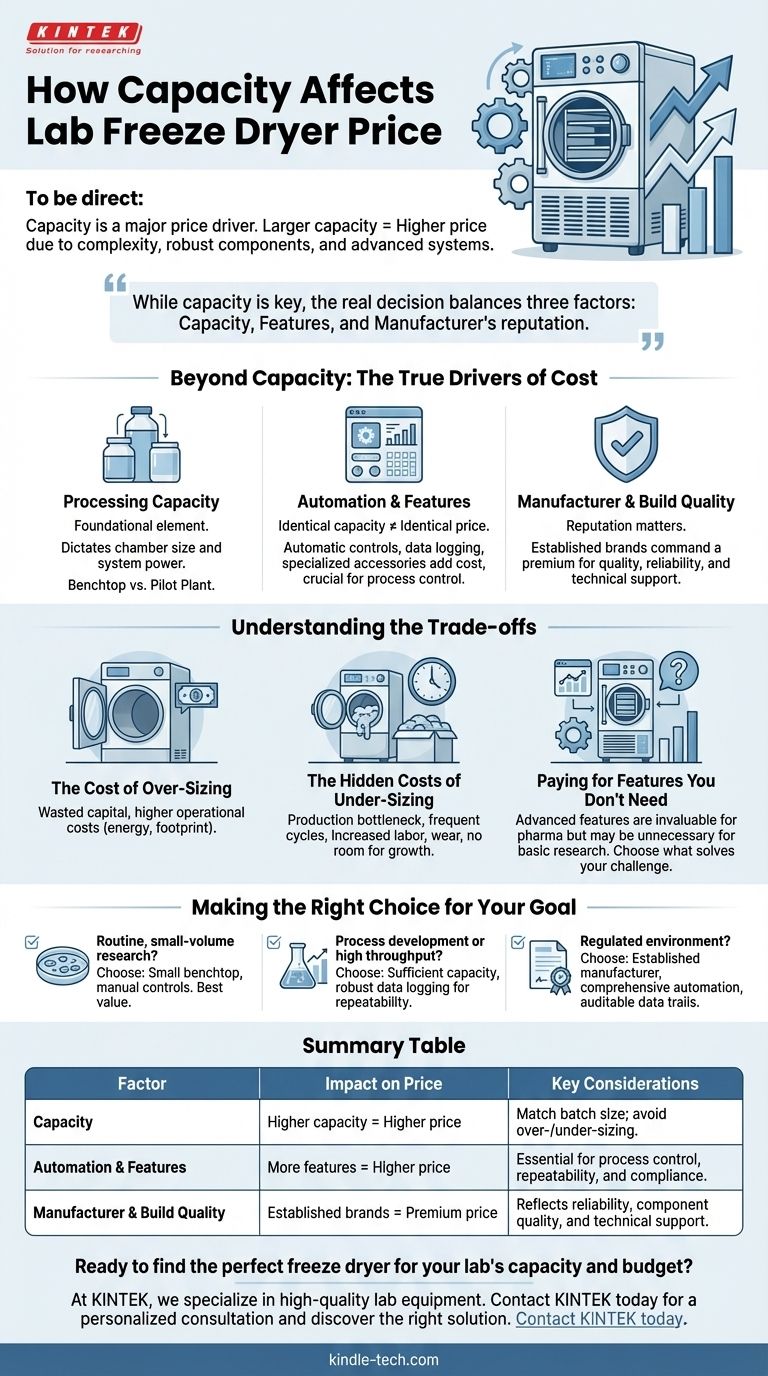

To be direct, capacity is one of the most significant factors driving the price of a lab freeze dryer. A larger capacity—the volume of material the unit can process in a single cycle—almost always correlates with a higher price due to greater manufacturing complexity, more robust components, and the advanced systems needed to manage larger loads.

While it's easy to focus on capacity as the main price driver, the real decision rests on a balance of three factors: the capacity you need, the features your application demands, and the manufacturer's reputation for reliability. Evaluating price without this context often leads to a poor investment.

Beyond Capacity: The True Drivers of Cost

A freeze dryer's price tag is a reflection of more than just its size. Understanding the key components of its cost allows you to assess the true value for your specific laboratory needs.

Pillar 1: Processing Capacity

Capacity is the foundational element of cost. It dictates the physical size of the freeze dryer's chamber and the power of its supporting systems.

This is measured in the volume or weight of material that can be processed at one time. A small benchtop model for occasional sample prep has fundamentally different engineering requirements than a large pilot plant unit designed for high-throughput batch processing.

Pillar 2: Automation and Features

Two freeze dryers with identical capacity can have vastly different prices based on their feature set. These additions are not cosmetic; they directly impact process control and repeatability.

Features like automatic controls for pre-freezing and drying cycles, sophisticated data logging for documentation, and specialized accessories for different sample types (like vials or flasks) all add to the final cost. These are essential for process development and regulated environments.

Pillar 3: Manufacturer and Build Quality

The manufacturer's reputation plays a critical role in pricing. This isn't just about brand recognition; it's about proven performance and reliability.

Established brands with a long history of innovation often command higher prices. This premium reflects a commitment to quality components, robust engineering, and responsive technical support, which are crucial for minimizing downtime in a professional setting.

Understanding the Trade-offs

Choosing a freeze dryer is an exercise in balancing capabilities with budget. Focusing solely on minimizing the initial price can lead to significant long-term costs.

The Cost of Over-Sizing

Purchasing a unit with far more capacity than you need is a common mistake. This results in wasted capital upfront and higher operational costs due to increased energy consumption and a larger laboratory footprint.

The Hidden Costs of Under-Sizing

A more damaging error is selecting a unit that is too small for your needs. This creates a production bottleneck, forcing you to run more frequent cycles, which increases labor costs and component wear. It also leaves no room for your processes to scale.

Paying for Features You Don't Need

Advanced data logging and automatic cycle programming are invaluable for pharmaceutical development but may be unnecessary for a basic academic research application. The most expensive freeze dryer is not always the best one; the best unit is the one whose features directly solve your specific challenge.

Making the Right Choice for Your Goal

To select the most suitable freeze dryer, align your choice with your primary operational requirements.

- If your primary focus is routine, small-volume research: A smaller benchtop model with manual controls will likely provide the best value without overspending on unneeded features.

- If your primary focus is process development or high throughput: Invest in a model with sufficient capacity and robust data logging to ensure your results are repeatable and scalable.

- If your primary focus is working in a regulated environment: Prioritize models from established manufacturers with comprehensive automation and auditable data trails, as this is non-negotiable for compliance.

Ultimately, a clear assessment of your sample throughput and required level of process control will guide you to the most cost-effective investment for your lab.

Summary Table:

| Factor | Impact on Price | Key Considerations |

|---|---|---|

| Capacity | Higher capacity = Higher price | Match to your batch size; avoid over- or under-sizing. |

| Automation & Features | More features = Higher price | Essential for process control, repeatability, and compliance. |

| Manufacturer & Build Quality | Established brands = Premium price | Reflects reliability, component quality, and technical support. |

Ready to find the perfect freeze dryer for your lab's capacity and budget?

At KINTEK, we specialize in providing high-quality lab equipment, including freeze dryers tailored to your specific research, process development, or regulated environment needs. Our experts will help you balance capacity, features, and cost to ensure you make a smart, long-term investment.

Contact KINTEK today for a personalized consultation and discover the right solution for your laboratory.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the eutectic point in lyophilization? Master the Critical Temperature for Success

- What role does freeze-drying play in biotechnology? Preserving Biological Integrity for Long-Term Stability

- What are the characteristics of crystalline materials in lyophilization? Master Crystal Size & Eutectic Temperature

- What is a lyophilizer and how does it work? Unlock Superior Preservation for High-Value Materials

- Can you separate the solid and liquid in a solution by filtering? No, and Here's Why