At its core, carbon coating is a process that builds a new, high-performance surface on an object, atom by atom. This is achieved by vaporizing a solid carbon source material inside a vacuum chamber and allowing the carbon atoms to deposit as a thin, dense, and highly-adherent film. This film fundamentally alters the object's surface properties to make it more durable, chemically stable, or electrically conductive.

The purpose of carbon coating is not simply to cover a material, but to fundamentally re-engineer its surface at an atomic level. The process uses vacuum technology to create an ultra-thin carbon layer that becomes an integral part of the component, granting it entirely new capabilities.

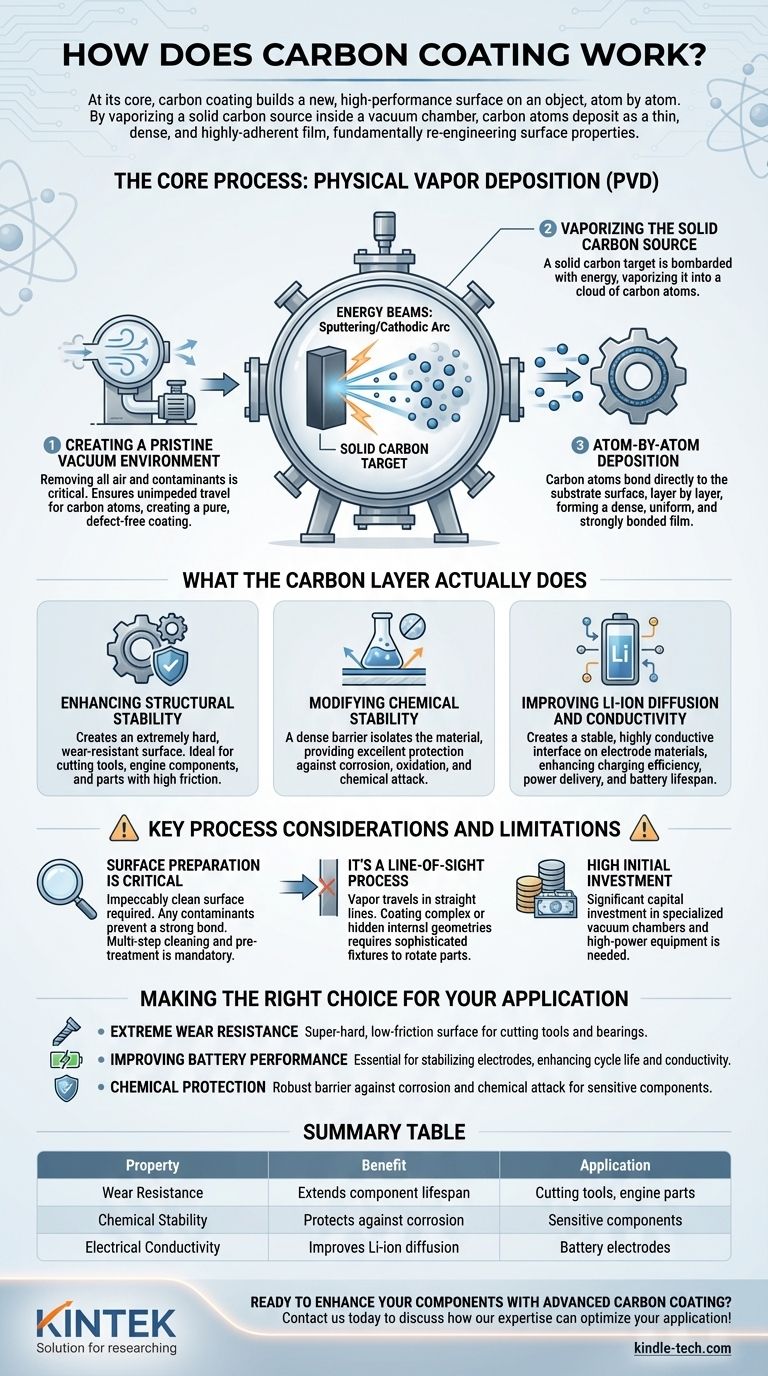

The Core Process: Physical Vapor Deposition (PVD)

Most modern carbon coatings are applied using a method called Physical Vapor Deposition (PVD). This is a family of processes that all share a common sequence of transforming a solid material into a vapor, which then condenses onto a substrate to form the coating.

Step 1: Creating a Pristine Vacuum Environment

The entire process takes place within a sealed vacuum chamber.

Removing all the air and other contaminants is critical. This ensures the carbon atoms can travel unimpeded to the target object and that the final coating is pure and free from defects.

Step 2: Vaporizing the Solid Carbon Source

A solid block or rod of pure carbon material, known as the 'target', is placed inside the chamber.

This target is then bombarded with energy to vaporize it, essentially turning the solid carbon into a cloud of atoms. This can be achieved through several methods, including sputtering (using ion bombardment) or using a cathodic arc (a high-current electric arc).

Step 3: Atom-by-Atom Deposition

The vaporized carbon atoms travel through the vacuum and strike the surface of the object being coated (the 'substrate').

Upon impact, these atoms bond directly to the substrate's surface. This deposition occurs layer by layer, atom by atom, creating a film that is exceptionally dense, uniform, and strongly bonded to the material underneath.

What the Carbon Layer Actually Does

Once applied, the carbon film imparts powerful new properties to the substrate. The specific benefits depend on the application, but they generally fall into three categories.

Enhancing Structural Stability

The strong atomic bonds in the carbon coating create a surface that is extremely hard and resistant to wear and tear.

This makes it ideal for cutting tools, engine components, and other parts subject to high friction, as the coating acts as a durable protective barrier.

Modifying Chemical Stability

Carbon is a relatively inert element. A dense carbon coating creates a barrier that isolates the underlying material from its environment.

This provides excellent protection against corrosion, oxidation, and chemical attack, extending the life of the component.

Improving Li-ion Diffusion and Conductivity

In specialized applications like lithium-ion batteries, a carbon coating plays a critical role.

It creates a stable and highly conductive interface on the electrode materials. This improves the flow of lithium ions, which enhances charging efficiency, power delivery, and the overall lifespan of the battery.

Key Process Considerations and Limitations

While powerful, the PVD process for carbon coating has specific requirements and trade-offs that must be understood for successful implementation.

Surface Preparation is Critical

The PVD process requires an impeccably clean surface for the coating to adhere properly.

Any microscopic oil, dust, or oxide layer on the substrate will prevent a strong bond from forming. This is why a multi-step cleaning and pre-treatment phase is a mandatory part of the workflow.

It's a Line-of-Sight Process

The vaporized carbon atoms travel in a relatively straight line from the target to the substrate.

This means that coating complex internal geometries or the back side of an object can be challenging without sophisticated fixtures that rotate the parts during the process.

High Initial Investment

PVD technology requires significant capital investment. The vacuum chambers, high-power energy sources, and control systems are specialized and expensive pieces of equipment.

Making the Right Choice for Your Application

Understanding your primary goal is key to determining if carbon coating is the appropriate solution.

- If your primary focus is extreme wear resistance: A carbon coating creates a super-hard, low-friction surface ideal for protecting cutting tools, bearings, or engine parts.

- If your primary focus is improving battery performance: Carbon coating is an essential technique for stabilizing electrode materials, which enhances cycle life and electrical conductivity.

- If your primary focus is chemical protection: The inert and dense nature of the coating provides a robust barrier against corrosion and chemical attack on sensitive components.

Ultimately, carbon coating is a precise surface engineering tool that solves specific material challenges by building a better surface from the atom up.

Summary Table:

| Property | Benefit | Application |

|---|---|---|

| Wear Resistance | Extends component lifespan | Cutting tools, engine parts |

| Chemical Stability | Protects against corrosion | Sensitive components |

| Electrical Conductivity | Improves Li-ion diffusion | Battery electrodes |

Ready to enhance your components with advanced carbon coating? KINTEK specializes in precision lab equipment and consumables for surface engineering. Our solutions help you achieve superior wear resistance, chemical stability, and battery performance. Contact us today to discuss how our expertise can optimize your application!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Why heat treat LLZO in an argon glove box? Remove Passivation Layers & Ensure Superior Surface Purity

- What procedures should be followed before using nickel or copper foam? Ensure Optimal Performance and Reliability

- What core data does a multi-channel battery test system monitor? Enhance Zinc Anode Cycling Stability Analysis

- What are the material properties of carbon cloth? Harness Strength, Conductivity & Flexibility

- What tools are used for battery research and material processing? Enhance Your Lab's Material Prep with KINTEK

- What are the advantages of carbon coating? Enhance Stability & Conductivity for Your Materials

- What are the real life applications of graphite? Powering Batteries, Industry, and Technology

- What are the primary functions of stainless steel wire mesh in air cathodes? Enhance Your Battery Design & Conductivity