In the world of food preservation, freeze-drying offers a distinct set of advantages for dairy products by preserving them in a state remarkably close to their fresh form. This process avoids the high heat of conventional dehydration, which allows for superior retention of nutrition, flavor, and texture. The resulting products are lightweight, shelf-stable without refrigeration, and can be easily reconstituted.

Freeze-drying is not merely a method of removing water; it is a low-temperature process that locks in the original biological and sensory qualities of dairy. By avoiding heat damage, it preserves the very essence of the product, making it superior for high-value applications where quality is non-negotiable.

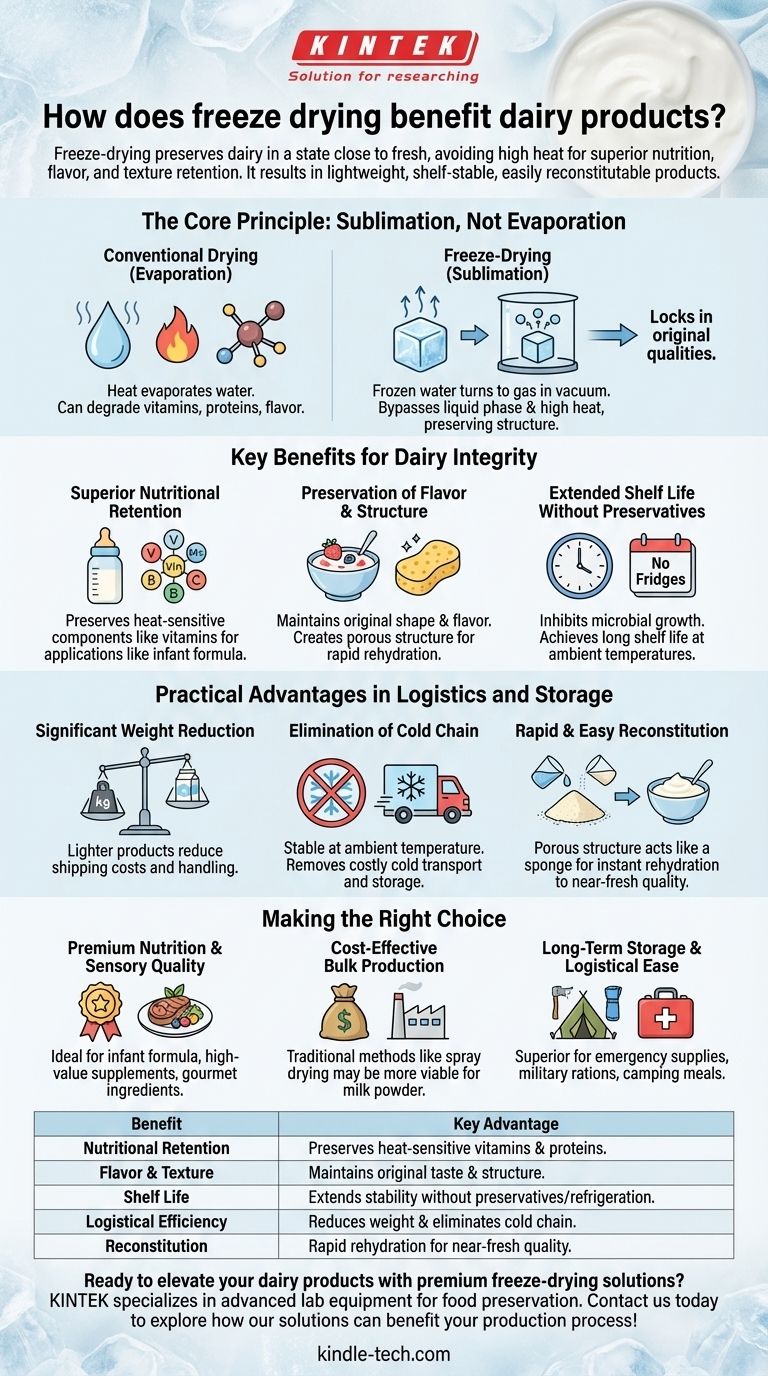

The Core Principle: Sublimation, Not Evaporation

To understand the benefits of freeze-drying, it is essential to grasp the fundamental science that separates it from other methods.

How It Works: Freezing and Vacuum

First, the dairy product is frozen solid. Then, it is placed in a strong vacuum chamber.

This vacuum allows the frozen water crystals to turn directly from a solid (ice) into a gas (water vapor) without ever becoming a liquid. This physical process is called sublimation.

The Advantage Over Heat-Drying

Conventional drying methods rely on heat to evaporate water. This heat can degrade sensitive vitamins, denature proteins, and alter the flavor and color of dairy products.

Freeze-drying bypasses this damaging heat stage entirely, gently removing water while leaving the product's core structure and nutritional profile largely intact.

Key Benefits for Dairy Integrity

This low-temperature process translates into tangible benefits for the final product, from its nutritional value to its shelf life.

Superior Nutritional Retention

The absence of high heat means that heat-sensitive components like vitamins and other biologically active compounds are preserved. This makes the method especially suitable for nutritionally critical products like infant formula.

Preservation of Flavor and Structure

Because the water is removed from a frozen structure, the product's physical shape is maintained. This creates a porous material that not only retains its original flavor and appearance but also allows for rapid and complete reconstitution when water is added back.

Extended Shelf Life Without Preservatives

By removing virtually all water, freeze-drying inhibits the growth of bacteria, molds, and other microorganisms that cause spoilage. This achieves a long shelf life without the need for chemical preservatives or refrigeration.

Practical Advantages in Logistics and Storage

Beyond product quality, freeze-drying solves critical operational challenges related to transport and storage.

Significant Weight Reduction

Water is heavy. Removing it makes dairy products like milk, yogurt, and ice cream significantly lighter, reducing shipping costs and making them easier to handle and transport.

Elimination of Cold Chain Requirements

Once freeze-dried, dairy products are stable at ambient temperatures. This eliminates the need for a costly and energy-intensive cold chain (refrigeration or freezing) during shipping and storage.

Rapid and Easy Reconstitution

The porous structure created during sublimation acts like a sponge. This allows products to rehydrate almost instantly when mixed with water, returning to a quality that is considered next to fresh.

Understanding the Trade-offs

While highly effective, freeze-drying is not a universal solution. It involves clear trade-offs that must be considered.

Higher Operational Costs

Freeze-drying equipment is a significant capital investment, and the process is more energy-intensive and time-consuming than conventional methods like spray drying. This results in a higher cost per unit for the final product.

Not Ideal for All Textures

While excellent for powders or solid pieces (like yogurt melts or ice cream bites), the final texture upon reconstitution, though very good, may not be a perfect replication of the original fresh product.

Making the Right Choice for Your Product

The decision to use freeze-drying should be driven by the specific goals for your dairy product.

- If your primary focus is premium nutrition and sensory quality: Freeze-drying is the unparalleled choice, ideal for infant formula, high-value supplements, or gourmet food ingredients.

- If your primary focus is cost-effective bulk production: Traditional methods like spray drying for milk powder may be more economically viable despite the lower quality.

- If your primary focus is long-term storage and logistical ease: The shelf stability and lack of refrigeration requirements make freeze-drying superior for emergency food supplies, military rations, and camping meals.

Ultimately, freeze-drying empowers you to preserve the inherent value of dairy, delivering a superior product where quality and integrity are paramount.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Nutritional Retention | Preserves heat-sensitive vitamins and proteins. |

| Flavor & Texture | Maintains original taste and structure. |

| Shelf Life | Extends stability without preservatives or refrigeration. |

| Logistical Efficiency | Reduces weight and eliminates cold chain requirements. |

| Reconstitution | Rapid rehydration for near-fresh quality. |

Ready to elevate your dairy products with premium freeze-drying solutions? KINTEK specializes in advanced lab equipment for food preservation, helping you achieve superior quality, extended shelf life, and logistical efficiency. Whether you're developing infant formula, gourmet ingredients, or emergency rations, our expertise ensures your dairy products retain their highest nutritional and sensory value. Contact us today to explore how our solutions can benefit your production process!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP