In short, freeze drying technology contributes to future innovation not by changing its fundamental process, but by applying its unique preservation capabilities to increasingly complex and sensitive materials. Its future lies in enabling breakthroughs in fields like advanced pharmaceuticals, functional foods, and material science, where maintaining the precise structure and bio-activity of a substance is critical.

The core driver of future innovation is not the freeze dryer itself, but what it preserves. By removing water without heat, it protects the delicate molecular architecture of everything from life-saving medicines to living microorganisms, making the unstable stable and unlocking new product possibilities.

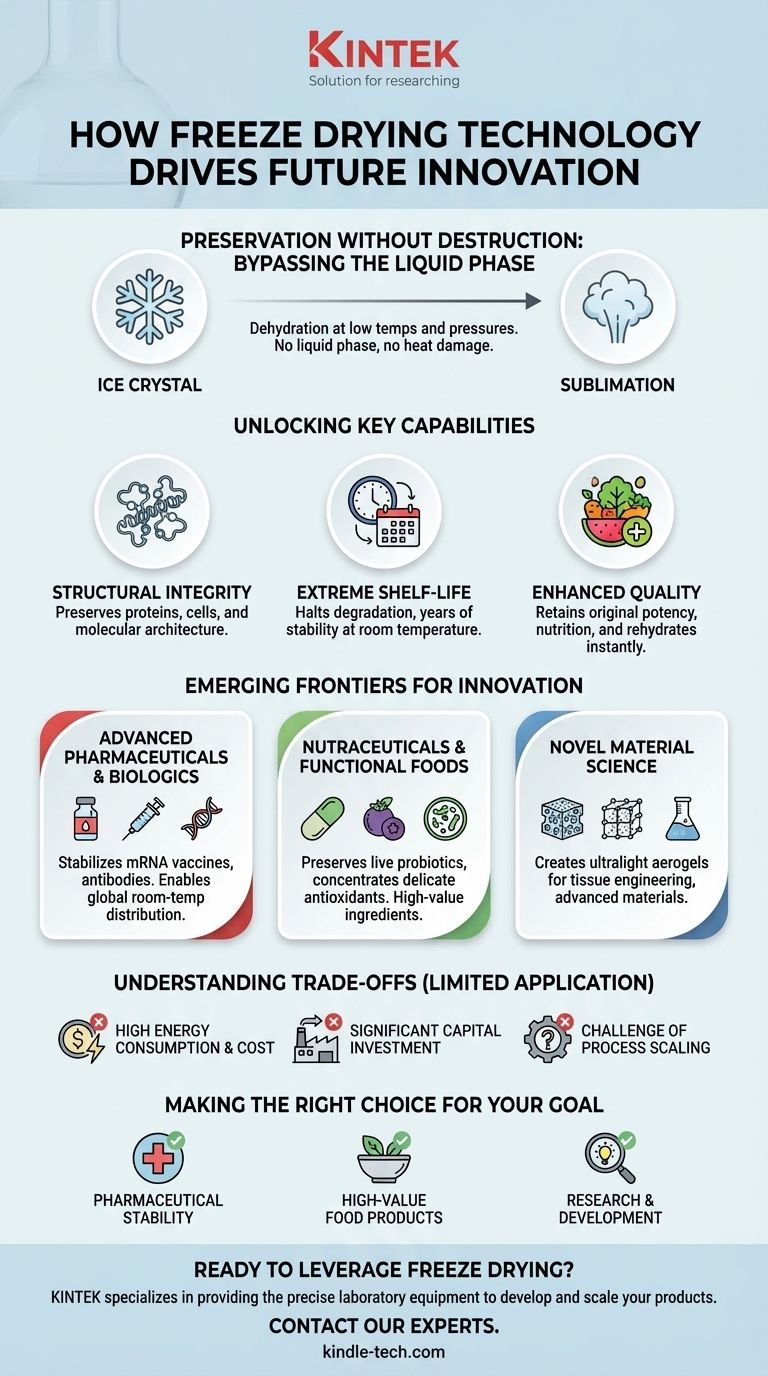

The Principle Driving Innovation: Preservation Without Destruction

To understand the future of freeze drying, you must first understand its core advantage over all other preservation methods. It is a process of dehydration at low temperatures and pressures.

Why This Matters: Bypassing the Liquid Phase

Conventional drying uses heat to evaporate water. This heat can destroy or "denature" the very molecules you are trying to preserve, altering their shape and function.

Freeze drying, or lyophilization, avoids this entirely. It freezes the material, then lowers the pressure, causing the ice to turn directly into vapor in a process called sublimation. By bypassing the destructive liquid water phase and damaging heat, the product's original molecular structure remains almost perfectly intact.

The Result: Unlocking Three Key Capabilities

This unique process grants three powerful benefits that form the foundation for future applications:

- Structural and Biological Integrity: It preserves the delicate structures of proteins, enzymes, and even whole cells.

- Extreme Shelf-Life: Removing water halts nearly all biological and chemical degradation, enabling years of stability without refrigeration.

- Enhanced Quality: The final product retains its original potency, nutritional value, and physical form, rehydrating instantly.

Emerging Frontiers for Freeze Drying Technology

These core capabilities are pushing freeze drying beyond traditional uses and into new, high-value sectors.

Advanced Pharmaceuticals and Biologics

The most significant impact will be in medicine. Modern biologics, such as mRNA vaccines, monoclonal antibodies, and cell-based therapies, are incredibly effective but notoriously unstable in liquid form.

Freeze drying is becoming the default method for turning these fragile liquids into stable powders. This allows them to be shipped and stored at room temperature, dramatically improving global access to next-generation treatments.

Nutraceuticals and Functional Foods

The food industry is moving beyond simple preservation. Freeze drying is being used to create high-value functional ingredients, like preserving live probiotic cultures for gut health or concentrating delicate antioxidants from superfruits.

It also allows for the production of nutrient-dense, lightweight foods for specialized applications like military rations, astronaut meals, and high-performance athletic supplements, where nutritional integrity is paramount.

Novel Material Science

An exciting, non-biological application is in material science. By freeze drying certain gels, engineers can create ultralight, highly porous structures known as aerogels.

This same principle can be applied to create scaffolds for tissue engineering, where a biocompatible structure is needed to guide cell growth, or to develop new types of insulation and catalyst materials.

Understanding the Inherent Trade-offs

Despite its advantages, freeze drying is not a universal solution. Its application is limited by significant practical and economic constraints.

High Energy Consumption and Cost

The process of freezing and then pulling a deep vacuum is extremely energy-intensive. A single cycle can take days to complete, making the operational cost far higher than heat-based drying.

Significant Capital Investment

Industrial-scale freeze dryers are complex, specialized machines that represent a major capital expenditure. This high barrier to entry reserves the technology for products where the value of preservation justifies the cost.

The Challenge of Process Scaling

A formulation that works perfectly in a small lab freeze dryer may fail at an industrial scale. Optimizing a cycle for a new product is a complex science, requiring expertise to ensure consistent quality and prevent costly batch failures.

Making the Right Choice for Your Goal

Applying freeze drying successfully requires aligning its unique strengths with a specific strategic objective.

- If your primary focus is Pharmaceutical Stability: Use freeze drying to make fragile, high-value biologics and vaccines distributable and stable at ambient temperatures.

- If your primary focus is High-Value Food Products: Leverage it to create functional ingredients or premium consumer goods where preserving nutritional content and bio-activity creates a clear market advantage.

- If your primary focus is Research & Development: Employ freeze drying to perfectly preserve delicate biological samples for analysis or to engineer novel materials with highly controlled porous structures.

Ultimately, freeze drying is the key enabling technology for any field that needs to make the unstable durable and the fragile functional.

Summary Table:

| Key Application Area | Core Contribution of Freeze Drying |

|---|---|

| Advanced Pharmaceuticals | Stabilizes fragile biologics (mRNA, antibodies) for global distribution without refrigeration. |

| Functional Foods & Nutraceuticals | Preserves live probiotics, antioxidants, and nutritional integrity for high-value ingredients. |

| Material Science | Creates ultralight, porous structures (aerogels) for tissue engineering and advanced materials. |

| Research & Development | Enables long-term preservation of sensitive biological samples and novel material prototypes. |

Ready to leverage freeze drying for your next innovation?

KINTEK specializes in providing the precise laboratory equipment and consumables you need to develop and scale your next-generation products. Whether you are stabilizing a new biologic, creating a functional food ingredient, or engineering a novel material, our expertise can help you optimize your process.

Contact our experts today to discuss how our solutions can preserve your most delicate materials and accelerate your R&D.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure