At its core, cannabis distillate is created not through a single extraction, but a multi-stage refinement process. It begins with a crude cannabis extract, which is then meticulously purified using a technique called short-path distillation. This process isolates a single cannabinoid, like THC or CBD, by leveraging its unique boiling point to separate it from virtually all other plant compounds.

The most critical thing to understand is that distillation is not about extracting oil from the plant, but about purifying a crude oil that has already been extracted. It's a process of separation and isolation, which is why the final product is so potent and pure.

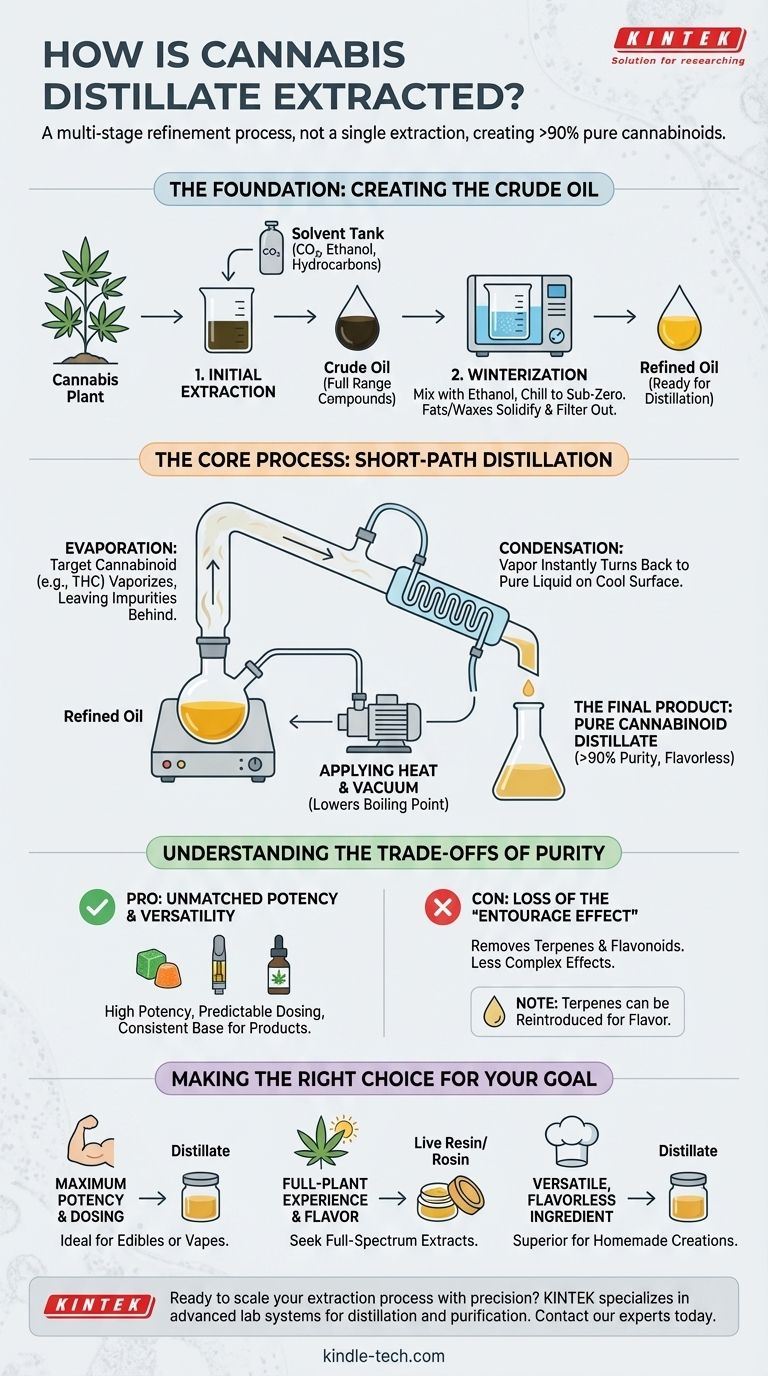

The Foundation: Creating the Crude Oil

Before any distillation can occur, a starting material is required. This "crude oil" is a basic, unrefined extract that contains the full range of compounds from the cannabis plant.

Step 1: Initial Extraction

The journey begins by using a solvent to strip the cannabinoids, terpenes, and other compounds from the raw plant material.

Common methods include using CO2, ethanol, or hydrocarbons (like butane). The goal of this initial step is simply to get all the desirable compounds out of the plant and into a concentrated oil form.

Step 2: Winterization

This crude oil contains undesirable materials like fats, waxes, and lipids. Winterization is the process of removing them.

The oil is mixed with ethanol and chilled to sub-zero temperatures. This causes the fats and waxes to solidify and separate, allowing them to be filtered out, leaving a more refined oil ready for the main event.

The Core Process: Short-Path Distillation

This is the key step that creates the final, pure distillate. It works by separating chemical compounds based on their different boiling points under vacuum pressure.

The Principle of Separation

Think of it like distilling alcohol. Different substances vaporize at different temperatures. Distillation equipment heats the refined cannabis oil precisely to the boiling point of the target cannabinoid (e.g., THC).

Applying Heat and Vacuum

The winterized oil is placed into a flask and heated. Crucially, this is done under a deep vacuum. The vacuum lowers the boiling point of the cannabinoids, allowing them to vaporize at a much lower temperature.

This prevents the high heat from destroying the very compounds the process is trying to isolate.

Evaporation and Condensation

As the oil heats, the target cannabinoid turns into a vapor, leaving heavier waxes, lipids, and other non-volatile impurities behind.

This vapor travels a very short distance (hence, "short-path") to a chilled condensing coil. Upon contact with the cool surface, the vapor instantly turns back into a pure liquid, which drips down into a separate collection flask.

The Final Product: A Pure Cannabinoid

The result of this process is a thick, translucent oil that is almost entirely composed of a single cannabinoid. This final distillate is often over 90% pure THC or CBD, but it has been stripped of the terpenes and flavonoids that provide flavor and aroma.

Understanding the Trade-offs of Purity

The extreme purity of distillate is both its greatest strength and its most significant weakness.

Pro: Unmatched Potency and Versatility

Because it is so concentrated, distillate offers incredibly high potency and predictable, repeatable dosing. Its lack of flavor and aroma makes it the perfect base for edibles, tinctures, and vape cartridges where consistency is paramount.

Con: Loss of the "Entourage Effect"

The primary drawback is the removal of nearly all other plant compounds. This eliminates the "entourage effect"—the theory that cannabinoids and terpenes work together synergistically to produce a more complex and nuanced set of effects. A distillate high is often described as one-dimensional compared to a full-spectrum extract.

Reintroducing Terpenes

To compensate for the lack of flavor and aroma, many producers add terpenes back into the finished distillate. These can be cannabis-derived terpenes (CDTs) or botanically-derived terpenes (BDTs), but this is a reformulation, not a preservation of the plant's original chemical profile.

Making the Right Choice for Your Goal

Understanding this process allows you to choose a product that aligns perfectly with your objective.

- If your primary focus is maximum potency and predictable dosing: Distillate is the ideal choice for its purity and straightforward effects, especially in edibles or vapes.

- If your primary focus is a full-plant experience with authentic flavor: You should seek out full-spectrum extracts like live resin or rosin, which preserve the natural terpenes.

- If your primary focus is a versatile, flavorless ingredient: Distillate is the superior option for making homemade edibles or tinctures without any cannabis taste.

By understanding how distillate is made, you can now look past the potency numbers and make an informed decision based on the kind of experience you want.

Summary Table:

| Process Step | Purpose | Key Details |

|---|---|---|

| Initial Extraction | Create crude oil from plant material. | Uses solvents like CO2, ethanol, or hydrocarbons. |

| Winterization | Remove fats, waxes, and lipids. | Oil is mixed with ethanol, chilled, and filtered. |

| Short-Path Distillation | Isolate pure cannabinoids (e.g., THC, CBD). | Heats oil under vacuum to vaporize and condense target compounds. |

| Final Product | Achieve high-purity distillate. | Result is >90% pure cannabinoid, often with terpenes added back. |

Ready to scale your cannabis extraction process with precision equipment? KINTEK specializes in advanced lab systems for distillation, purification, and more. Whether you're refining THC, CBD, or other cannabinoids, our solutions ensure purity, efficiency, and scalability. Contact our experts today to discuss how we can support your laboratory's unique needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the temperature effective for sterilization using autoclave? Achieve Sterile Conditions for Your Lab

- What are the considerations for autoclave? Ensure Sterilization Success and Safety

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- How does the lab autoclave work? Achieve Complete Sterilization with High-Pressure Steam