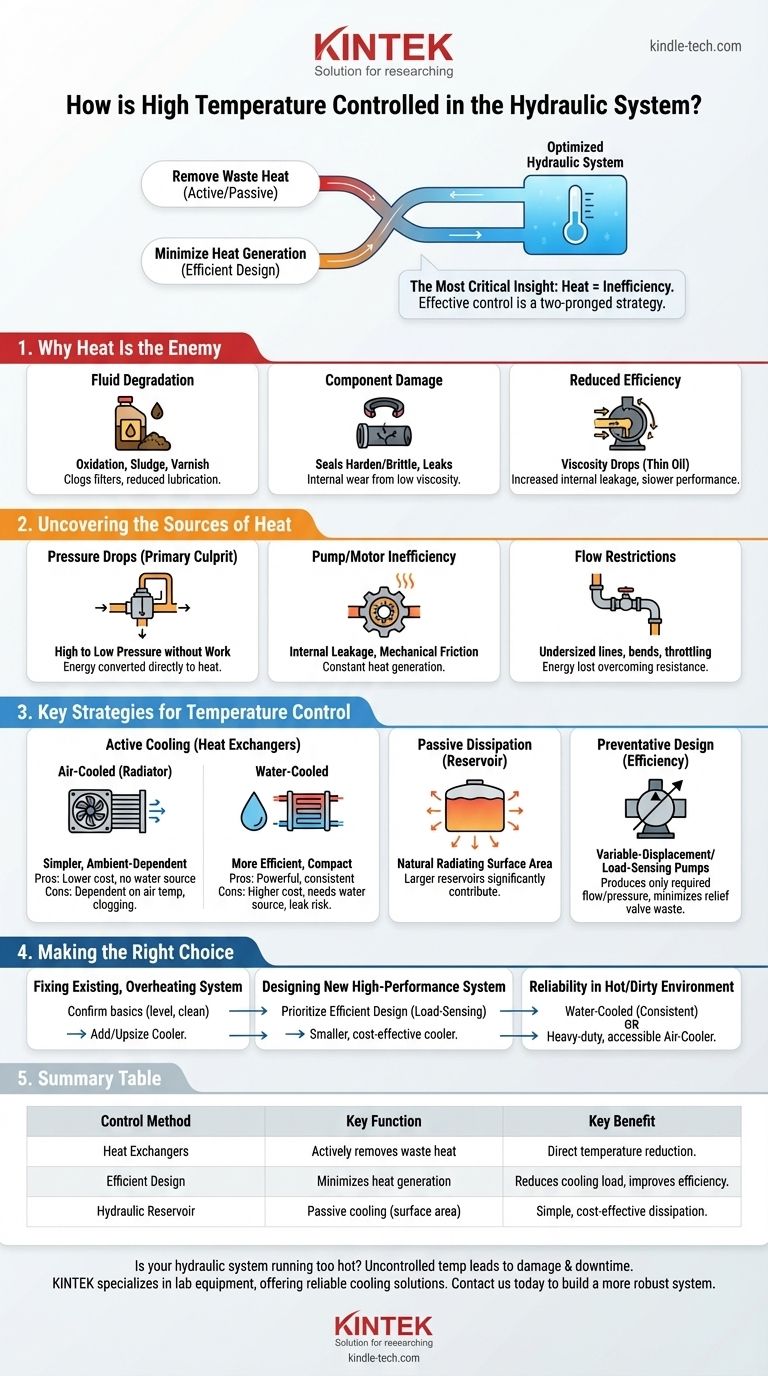

In a hydraulic system, high temperature is controlled by removing waste heat energy and minimizing its generation in the first place. This is achieved primarily through heat exchangers (coolers) that transfer heat out of the hydraulic fluid, but it is equally dependent on efficient system design that reduces energy loss from pressure drops and component friction.

The most critical insight is that heat in a hydraulic system is a direct measurement of inefficiency. Effective temperature control, therefore, is not just about adding a bigger cooler; it's a two-pronged strategy of designing a system that wastes less energy and effectively removing the waste heat that is unavoidably generated.

Why Heat Is the Enemy of Hydraulic Systems

Excessive heat is not merely a symptom; it is an active threat to the health and performance of your entire system. Understanding its consequences clarifies why control is non-negotiable.

Fluid Degradation

Heat accelerates the oxidation of hydraulic oil, forming sludge and varnish. This degrades the fluid's lubricating properties and can clog filters and small orifices within components.

Component Damage

Seals, gaskets, and hoses are particularly vulnerable. High temperatures cause them to harden and become brittle, leading to leaks. Internal metal components can also suffer from reduced fluid viscosity, leading to increased wear.

Reduced Efficiency

As fluid temperature rises, its viscosity drops. This thinning of the oil can increase internal leakage in pumps, motors, and cylinders, causing a noticeable drop in system performance and responsiveness.

Uncovering the Sources of Heat

Every hydraulic system generates some heat, but excessive heat is always a sign of wasted energy. This energy loss primarily occurs through pressure drops that do not perform useful work.

The Primary Culprit: Pressure Drops

Any time hydraulic fluid moves from an area of high pressure to low pressure without doing work, the energy is converted directly into heat. The most common source is a relief valve that is constantly bypassing fluid.

Inefficiency in Pumps and Motors

No component is 100% efficient. Internal leakage and mechanical friction within pumps and motors are constant sources of heat generation during operation.

Flow Restrictions and Fluid Friction

Undersized lines, sharp bends in tubing, and throttling valves all create resistance to flow. The energy required to overcome this resistance is lost as heat.

Key Strategies for Temperature Control

Controlling heat involves a combination of removing it from the system and preventing its creation.

Active Cooling: Heat Exchangers

This is the most direct method of temperature control. A portion of the hydraulic fluid is routed through a cooler to dissipate heat.

- Air-Cooled Heat Exchangers: These function like a car's radiator. A fan blows ambient air across fins to cool the hydraulic fluid flowing through them. They are simple and widely used.

- Water-Cooled Heat Exchangers: These use water to absorb heat from the hydraulic fluid. They are more efficient and compact than air coolers and are not affected by high ambient air temperatures.

Passive Dissipation: The Role of the Reservoir

The hydraulic reservoir (tank) provides a simple, passive form of cooling. Its large surface area allows heat to naturally radiate into the surrounding environment. A larger, well-designed reservoir can significantly contribute to system cooling.

Preventative Design: Building for Efficiency

The most elegant solution is to design a system that generates less heat from the start. Using variable-displacement, pressure-compensated, or load-sensing pumps ensures the system only produces the flow and pressure required for the task, drastically reducing energy loss through relief valves.

Understanding the Trade-offs

Choosing the right cooling strategy requires weighing the benefits and drawbacks of each approach.

Air-Cooled Systems: Simplicity and Accessibility

The main advantages of air coolers are their lower initial cost and simplicity, as they do not require a separate water source.

However, their performance is directly tied to the ambient air temperature, and their cooling fins can become clogged with dust and debris, requiring regular cleaning.

Water-Cooled Systems: Power and Compactness

Water coolers are significantly more effective at heat removal for their size. This makes them ideal for high-power systems or installations where space is limited.

Their primary disadvantages are a higher initial cost and the absolute requirement for a reliable source of clean, cool water. There is also a small risk of fluid cross-contamination if an internal leak occurs.

Making the Right Choice for Your System

Your optimal strategy depends entirely on your specific goals, environment, and whether you are designing a new system or fixing an existing one.

- If your primary focus is fixing an existing, overheating system: First, confirm the basics like correct fluid level and clean coolers. If the problem persists, adding or upsizing a cooler is the most direct solution.

- If your primary focus is designing a new high-performance system: Prioritize an efficient circuit design using load-sensing or pressure-compensated pumps to minimize waste heat from the start. This allows for a smaller, more cost-effective cooler.

- If your primary focus is reliability in a hot or dirty environment: A water-cooled system offers more consistent performance. If that is not an option, select a heavy-duty, oversized air cooler that is easy to access for frequent cleaning.

Ultimately, effective thermal management is the foundation of a reliable, efficient, and long-lasting hydraulic system.

Summary Table:

| Control Method | Key Function | Key Benefit |

|---|---|---|

| Heat Exchangers (Coolers) | Actively removes waste heat from hydraulic fluid. | Direct temperature reduction. |

| Efficient System Design | Minimizes heat generation from pressure drops and friction. | Reduces the cooling load, improving overall efficiency. |

| Hydraulic Reservoir | Provides passive cooling through its large surface area. | Simple, cost-effective heat dissipation. |

Is your hydraulic system running too hot? Uncontrolled temperature leads to fluid degradation, component damage, and costly downtime. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable solutions for maintaining optimal system performance. Our experts can help you select the right cooling strategy or components to ensure your hydraulic systems run reliably and efficiently. Contact us today to discuss your specific thermal management challenges and let us help you build a more robust system.

Visual Guide

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Lab Heat Press

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

People Also Ask

- Why is KBr inactive in IR? The Key to Transparent Sample Analysis

- How much force does a hydraulic press use? From 1 to 50,000 Tons of Controlled Power

- What is uniaxial pressing? A Fast, Cost-Effective Powder Compaction Method

- What happens to hydraulic oil when hot? Prevent Viscosity Breakdown and Costly Oxidation

- What are the samples for XRF analysis? A Guide to Preparing Solids, Powders, and Liquids

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the relationship between forces in a hydraulic system? Unlock the Power of Force Multiplication

- What is the primary function of a laboratory hydraulic press in solid-state batteries? Achieve Optimal Densification