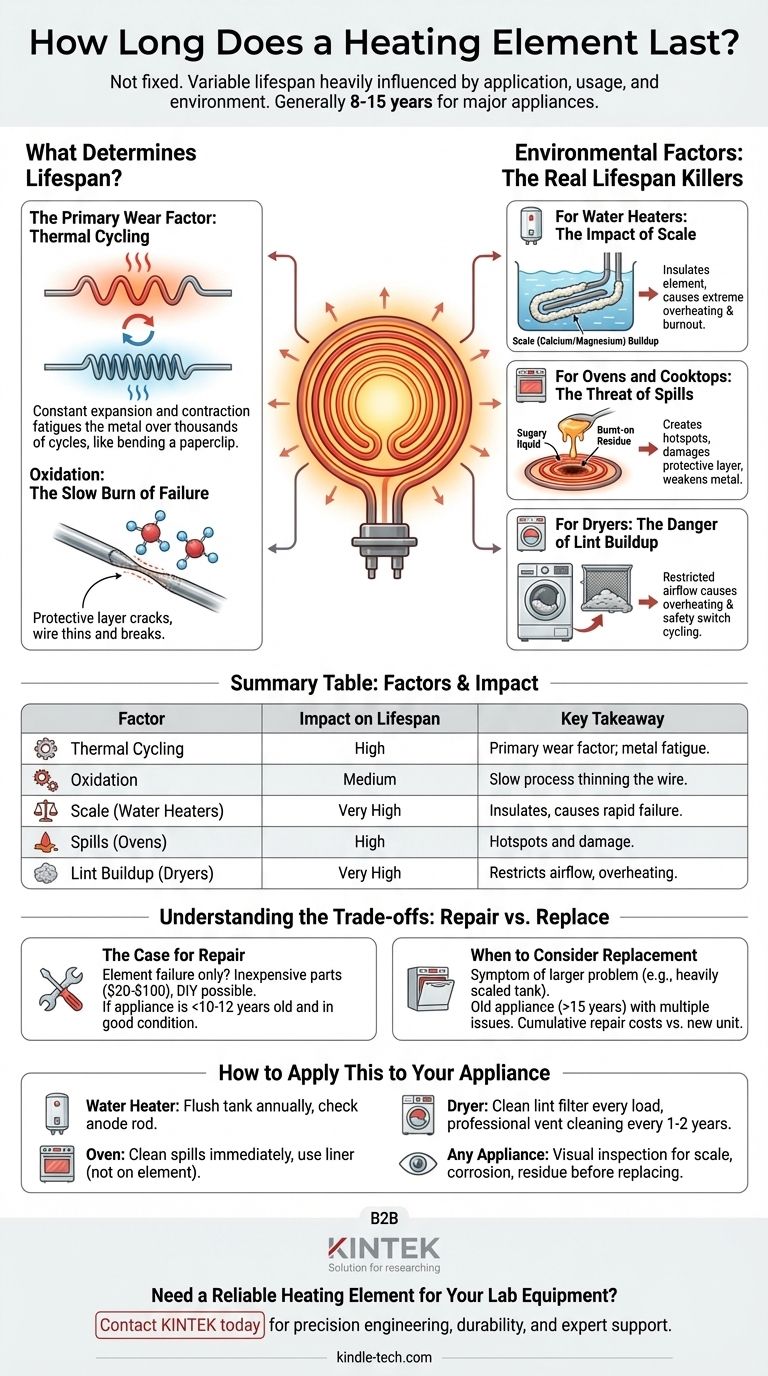

The lifespan of a heating element is not a fixed number, but a variable heavily influenced by its application, usage frequency, and operating environment. For major appliances, you can generally expect a heating element to last between 8 and 15 years, but this range can be significantly shorter or longer depending on several key factors.

The core takeaway is that heating elements rarely fail from age alone. Their failure is almost always accelerated by external conditions like mineral buildup, physical residue, or intense, frequent thermal cycles. Understanding these factors is the key to maximizing lifespan and diagnosing problems.

What Determines an Element's Lifespan?

A heating element's job is to convert electrical energy into heat. This inherently stressful process is what dictates its operational life.

The Principle of Resistance Heating

All conventional heating elements operate on a simple principle: electrical resistance. Electricity is forced through a material that resists its flow, typically a nichrome (nickel-chromium) alloy wire.

This resistance causes the wire to heat up intensely, glowing red hot and radiating thermal energy. This process is highly effective but puts immense stress on the element's material.

Thermal Cycling: The Primary Wear Factor

The biggest factor in an element's lifespan is thermal stress. Each time you turn the appliance on, the element rapidly heats and expands. When you turn it off, it cools and contracts.

This constant expansion and contraction, known as thermal cycling, is like bending a paperclip back and forth. Over thousands of cycles, it creates microscopic cracks and fatigues the metal, eventually leading to a break in the wire.

Oxidation: The Slow Burn of Failure

At high temperatures, the surface of the nichrome wire reacts with oxygen in the air, forming a protective layer of chromium oxide. This layer is crucial, as it prevents the element from burning out quickly.

However, over time and with repeated thermal cycling, this protective layer can crack or flake off. This exposes fresh metal underneath, which then oxidizes. This process slowly thins the element wire until it becomes too thin to carry the current and breaks.

Environmental Factors: The Real Lifespan Killers

While internal wear is inevitable, external factors are what most often cause premature failure. The specific threats depend entirely on the appliance.

For Water Heaters: The Impact of Scale

In an electric water heater, the element is submerged in water. Minerals in the water, especially calcium and magnesium, precipitate out and form a hard, crusty layer on the element called scale.

This scale acts as an insulator, forcing the element to work much harder and get much hotter to heat the surrounding water. This extreme overheating drastically accelerates fatigue and oxidation, causing the element to burn out. This is the #1 killer of water heater elements.

For Ovens and Cooktops: The Threat of Spills

In an oven or on an electric stovetop, food spills and grease are the main culprits. When a sugary or fatty liquid drips onto a hot element, it can cause a sudden, localized temperature shock.

More importantly, the burnt-on residue can eat away at the element's protective oxide layer, creating hotspots that weaken the metal and lead to a swift failure.

For Dryers: The Danger of Lint Buildup

An electric dryer's heating element requires constant airflow to dissipate its heat. If the lint filter or exhaust vent is clogged, this airflow is restricted.

Reduced airflow causes the element to overheat, triggering the high-limit safety thermostat to cut power. Constant cycling of this safety switch adds enormous stress, and the excessive heat dramatically shortens the element's life.

Understanding the Trade-offs: Repair vs. Replace

When an element fails, you face a decision. Understanding the context of the failure is key.

The Case for Repair

Repairing is often the best choice if the element itself is the only problem. Heating elements are typically inexpensive parts (often $20-$100) and can be a straightforward DIY replacement for many appliances.

If the appliance is otherwise in good condition and less than 10-12 years old, replacing just the element is a very cost-effective solution.

When to Consider Replacement

You should consider replacing the entire appliance if the element failure is a symptom of a larger problem. For example, if a water heater element failed due to a heavily scaled tank, the tank itself may be near the end of its life.

Similarly, if an oven element fails on a 15-year-old appliance that also has a faulty control board, the cumulative cost and effort of repairs may not be worth it compared to investing in a new, more efficient unit.

How to Apply This to Your Appliance

Your goal should be to control the environmental factors that accelerate failure.

- If you own an electric water heater: Flush the tank annually to remove sediment and check the anode rod every few years. This directly combats scale buildup.

- If you own an electric oven: Clean up spills immediately. Use a liner on the bottom of the oven (not directly on the element) to catch drips.

- If you own an electric dryer: Clean the lint filter after every single load and have the full vent line professionally cleaned every 1-2 years.

- For any appliance: If an element fails, perform a quick visual inspection. Look for signs of scale, corrosion, or residue to understand why it failed before simply replacing it.

By understanding these principles, you move from reacting to failures to proactively managing the health and longevity of your appliances.

Summary Table:

| Factor | Impact on Lifespan | Key Takeaway |

|---|---|---|

| Thermal Cycling | High | The primary wear factor; each on/off cycle causes metal fatigue. |

| Oxidation | Medium | A slow, natural process that thins the element wire over time. |

| Scale (Water Heaters) | Very High | Insulates the element, causing it to overheat and fail quickly. |

| Spills (Ovens) | High | Burnt-on residue creates hotspots and damages the protective layer. |

| Lint Buildup (Dryers) | Very High | Restricts airflow, leading to overheating and safety switch cycling. |

Need a Reliable Heating Element for Your Lab Equipment?

Understanding the factors that lead to heating element failure is crucial for maintaining consistent, accurate results in your laboratory. KINTEK specializes in high-performance lab equipment and consumables, including durable, long-lasting heating elements designed to withstand the rigorous demands of scientific applications.

By choosing KINTEK, you benefit from:

- Precision Engineering: Our elements are built for stable, uniform heating, critical for your experiments.

- Durability: Designed to resist the common causes of premature failure, maximizing uptime.

- Expert Support: Get guidance on proper usage and maintenance to extend the life of your equipment.

Don't let a faulty heating element disrupt your workflow. Contact KINTEK today to find the perfect replacement or upgrade for your specific laboratory needs and ensure your research continues without interruption.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- Which material can be used as a heating element? Select the Right Element for Your Application

- What is the best substitute for tungsten? Choose the Right Material for Your Application

- Can tungsten be used as a heating element? Unlocking Extreme Heat for High-Temperature Applications

- How do resistive heating elements work? Unlock the Science of Efficient Heat Generation

- What is the advantage of molybdenum? Unlock Superior High-Temperature Performance

- What is the best electric heating element? Match the Right Material to Your Application's Needs

- How does a graphite heater work? Achieve Extreme Temperatures with Unmatched Precision

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere