The duration of hot isostatic pressing (HIP) is not a fixed number. While a complete cycle can range from a few hours to over 24 hours, the exact time is highly specific to the application. The total duration is a carefully engineered process determined by the material being treated, the size and mass of the components, and the desired final metallurgical properties.

The total time for a hot isostatic pressing cycle is dictated less by the equipment and more by the physics of the material itself. It is a sum of the time required to heat the part, "soak" it at peak temperature and pressure to achieve densification, and then cool it down safely—all of which are highly variable.

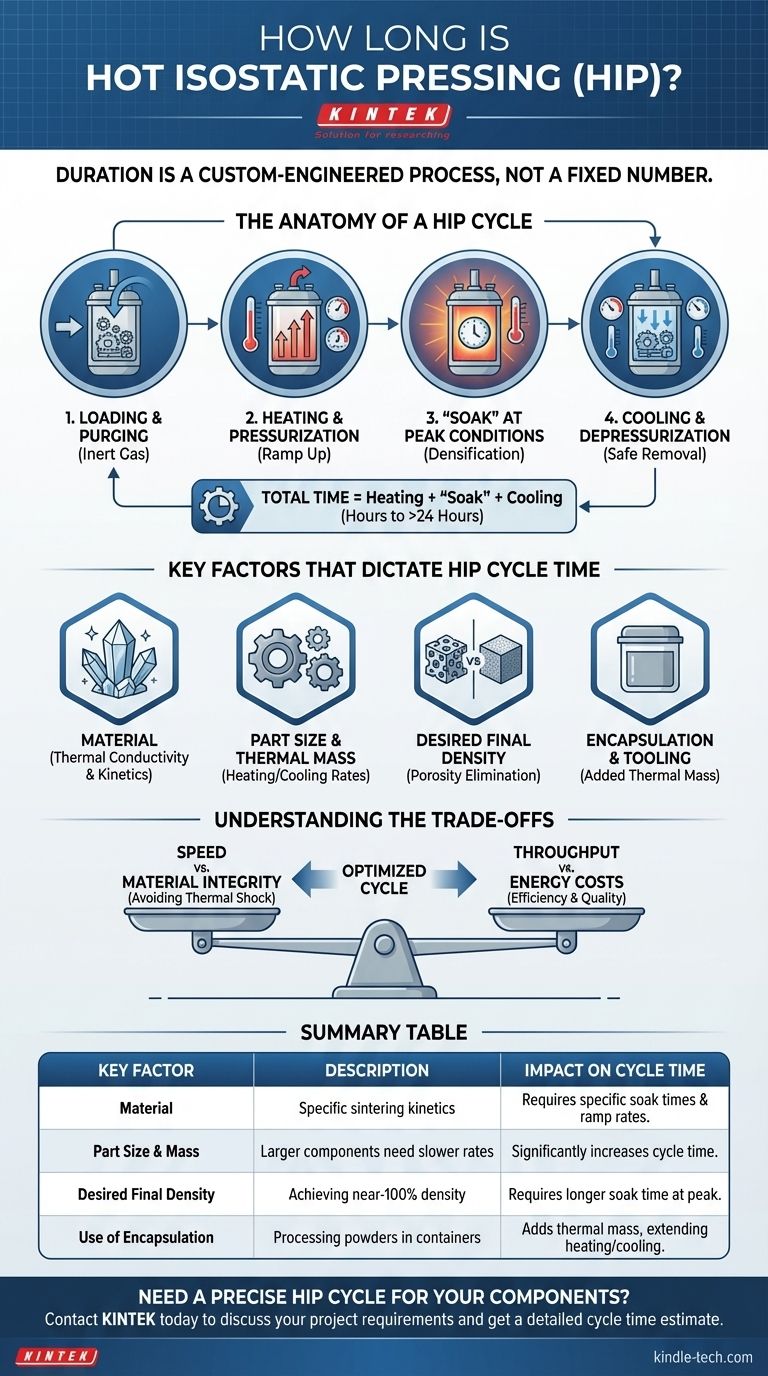

The Anatomy of a HIP Cycle

To understand the duration, you must first understand that the process is more than just holding a part at high temperature and pressure. A HIP cycle consists of several distinct, time-consuming phases.

Phase 1: Loading and Purging

Before any heating begins, parts are loaded into the cylindrical pressure vessel. The vessel is then sealed, and the ambient air is removed and replaced with an inert gas, typically argon. This ensures no reactive gases like oxygen are present at high temperatures.

Phase 2: Heating and Pressurization

The heating furnace within the vessel begins to raise the temperature. As the temperature rises, the pressure of the contained argon gas also increases. This ramp-up phase must be carefully controlled to avoid thermal shock to the components.

Phase 3: The "Soak" at Peak Conditions

This is the core of the process. The components are held at the target temperature (from 1000 to 2200°C) and pressure (from 100 to 200 MPa) for a specific period. This "soak time" allows for the closure of internal pores and the densification of the material.

Phase 4: Cooling and Depressurization

Once the soak is complete, the furnace is turned off, and the components begin to cool. This phase is just as critical as the heating phase and can be very long, especially for large parts or sensitive materials. The vessel is slowly depressurized as the temperature drops to a safe level for removal.

Key Factors That Dictate HIP Cycle Time

The significant variation in cycle time comes from a few key variables. Understanding them is crucial for planning and cost estimation.

The Material Being Processed

Different materials have different thermal conductivities and sintering kinetics. A dense superalloy will heat and cool differently than a powdered ceramic like silicon carbide, which may be sealed in a container.

Part Size and Thermal Mass

This is often the single most significant factor. A massive component, potentially weighing several tons, requires a very slow and controlled heating and cooling rate to ensure the temperature is uniform from the surface to the core. A large load of small parts has a similar effect due to its total thermal mass.

The Desired Final Density

The goal of HIP is often to achieve 100% theoretical density by eliminating internal porosity. The time required at peak temperature and pressure (the soak time) depends on the initial porosity and the rate at which the material's internal voids will creep and close under pressure.

Encapsulation and Tooling

When processing powders, the material is often sealed in a metal or glass container under a vacuum. The HIP cycle must account for the additional time needed to heat this container, which then transfers that heat to the powder within.

Understanding the Trade-offs

Optimizing a HIP cycle involves balancing competing priorities. It is not simply about making it as fast as possible.

Speed vs. Material Integrity

Rushing the heating or cooling phases can introduce massive thermal gradients within a part, leading to cracking or other defects. This completely negates the purpose of the process. The integrity of the final component is paramount.

Throughput vs. Energy Costs

HIP systems are extremely expensive to operate, primarily due to high energy consumption. Longer cycles mean lower equipment throughput and higher energy costs per part. Therefore, process engineers work to find the shortest possible cycle that still achieves the required quality standards.

Making the Right Choice for Your Goal

Your approach to determining the HIP cycle time depends on your specific objective.

- If your primary focus is process design: Your starting point is material data and thermal modeling, followed by empirical testing with smaller samples to validate the required soak time and safe heating/cooling rates.

- If your primary focus is sourcing HIP services: You must provide your supplier with the exact material specification, component geometry and weight, and the desired final density or mechanical properties. They will use this to engineer the correct cycle.

- If your primary focus is cost estimation: Remember to factor in the entire cycle time—loading, heating, soaking, cooling, and unloading—as the equipment is occupied for this whole duration, which directly impacts cost.

Ultimately, hot isostatic pressing should be viewed as a precise and controllable heat treatment, where time is a critical variable engineered to achieve a specific outcome.

Summary Table:

| Key Factor | Impact on HIP Cycle Time |

|---|---|

| Material | Different sintering kinetics and thermal conductivities require specific soak times and ramp rates. |

| Part Size & Mass | Larger, heavier components need slower heating/cooling to prevent thermal stress, significantly increasing cycle time. |

| Desired Final Density | Achieving near-100% density from a highly porous state requires a longer soak time at peak conditions. |

| Use of Encapsulation | Processing powders in a container adds thermal mass, extending the time needed to heat and cool the entire load. |

Need a Precise HIP Cycle for Your Components?

Determining the optimal hot isostatic pressing parameters is critical for achieving full densification without compromising material integrity. The experts at KINTEK specialize in designing and executing HIP processes tailored to your specific materials—from advanced superalloys to technical ceramics—and component geometries.

We provide the lab equipment and consumables necessary for R&D, process validation, and production. Let us help you engineer the perfect cycle for superior material performance.

Contact KINTEL today to discuss your project requirements and get a detailed cycle time estimate.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Anti-Cracking Press Mold for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the application of HIP? Eliminate Porosity for Superior Material Performance

- What are the parameters of HIP process? Master Temperature, Pressure, and Time for Superior Densification

- What are the disadvantages of hot isostatic pressing? The High Cost of Superior Material Performance

- What is the function of a Warm Isostatic Press (WIP) in all-solid-state pouch cells? Optimize Battery Density

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density

- What is the meaning of Hot Isostatic Pressing? Achieve 100% Density and Superior Material Integrity

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- Is hot isostatic pressing expensive? Invest in Unmatched Material Integrity for Critical Parts