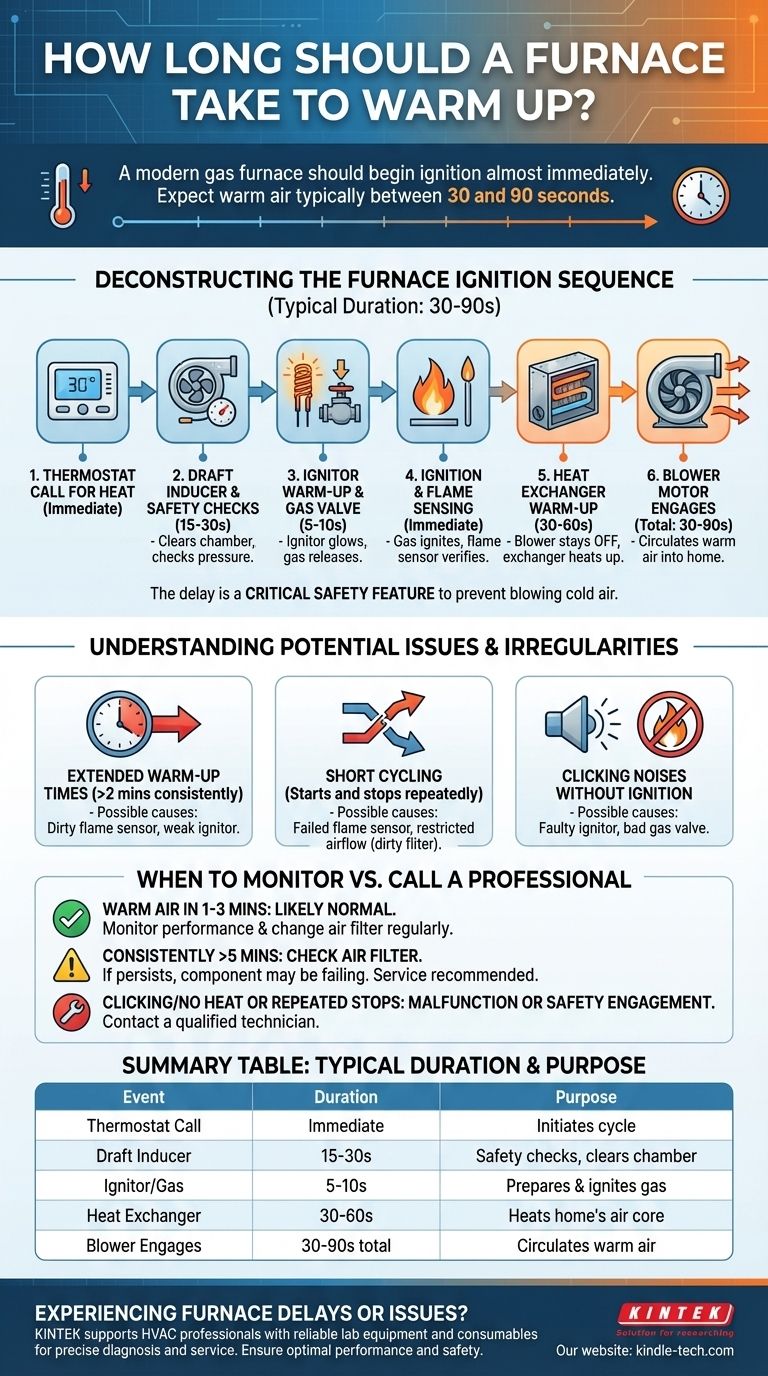

A modern gas furnace should begin its ignition sequence almost immediately, but you will not feel warm air instantly. It typically takes between 30 and 90 seconds for the internal safety checks to complete, the heat exchanger to warm up, and the main blower fan to start circulating heated air through your home.

The delay you experience before feeling heat is not a flaw; it is a critical safety and comfort feature. This intentional warm-up period ensures the system is operating safely and prevents the uncomfortable blast of cold air that would occur if the fan started immediately.

Deconstructing the Furnace Ignition Sequence

To understand why there's a delay, it's essential to know the step-by-step process your furnace follows every time it receives a signal to produce heat. This sequence is designed for safety, efficiency, and durability.

The Call for Heat

The entire process begins when your thermostat's sensor detects that the room temperature has dropped below your set point. It sends a low-voltage electrical signal to the furnace's control board, initiating the heating cycle.

Safety Checks and the Draft Inducer

The very first action the furnace takes is a safety check. A small fan, the draft inducer motor, turns on. Its job is to clear out any residual, unburnt gas from the combustion chamber and ensure the exhaust vent (flue) is not blocked.

Pressure sensors confirm that the inducer is creating the correct amount of negative pressure. If these sensors don't get the right reading, the system will halt the sequence to prevent dangerous exhaust gases from entering your home.

Ignitor and Gas Valve Activation

Once the safety checks pass, the control board sends power to the ignitor. In most modern furnaces, this is a hot surface ignitor that glows bright orange, reaching temperatures over 2,000°F.

Only after the ignitor is verified to be at the correct temperature will the control board open the gas valve, releasing a carefully measured flow of natural gas or propane.

Ignition and Flame Sensing

The hot ignitor immediately ignites the gas. A flame sensor—a small metal rod positioned in the path of the flames—confirms that a stable fire has been established.

If the flame sensor does not detect a flame within a few seconds, the control board will immediately shut the gas valve as a safety precaution. It may attempt the ignition cycle a few more times before entering a "lockout" mode, which requires a reset.

Warming the Heat Exchanger

With the burners successfully lit, the flames begin to heat a critical component called the heat exchanger. This metal chamber is what separates the toxic combustion gases from the breathable air that circulates through your home.

The blower fan remains off during this phase to allow the heat exchanger to get sufficiently hot. This crucial pause prevents the system from blowing cold air into your rooms.

The Blower Motor Engages

After a set time delay (typically 30-60 seconds after ignition) or once a temperature sensor confirms the heat exchanger is hot, the main blower motor turns on. It pulls cool air from your home, passes it over the exterior of the hot heat exchanger, and pushes the newly warmed air into your ductwork. This is the moment you begin to feel warm air from your vents.

Understanding Potential Issues and Irregularities

While a short delay is normal, certain symptoms during startup can indicate an underlying problem that requires attention.

Extended Warm-Up Times

If it consistently takes more than two minutes for the blower to start after the thermostat calls for heat, there could be an issue. This can be caused by a dirty flame sensor that struggles to detect the flame or a weakening ignitor that takes too long to get hot.

The Furnace Starts and Stops (Short Cycling)

If you hear the furnace ignite but it shuts down before the main blower ever starts, it's often a sign of a failed flame sensor. If the system runs for a few minutes and then shuts off, it could be short cycling due to restricted airflow from a clogged air filter, causing the heat exchanger to overheat.

Clicking Noises Without Ignition

A rapid clicking sound without any subsequent roar of burners usually points to a problem with the ignition system. This could be a cracked hot surface ignitor, a faulty spark ignitor, or a gas valve that isn't opening correctly.

When to Monitor and When to Call a Professional

Knowing the normal operating sequence empowers you to make an informed decision about your furnace's health.

- If your furnace delivers warm air within 1 to 3 minutes: This is likely normal operation. Continue to monitor its performance and change your air filter regularly.

- If the warm-up time is consistently longer than 5 minutes: First, check that your air filter is clean. If the problem persists, it indicates a component may be failing and service is recommended.

- If you hear clicking but get no heat, or the system starts and stops repeatedly: This signals a clear malfunction or a safety system engagement. You should contact a qualified HVAC technician for diagnosis and repair.

By understanding the normal sequence of your furnace, you can confidently distinguish between routine operation and a genuine call for professional service.

Summary Table:

| Event | Typical Duration | Purpose |

|---|---|---|

| Thermostat Call for Heat | Immediate | Initiates the heating cycle. |

| Draft Inducer & Safety Checks | 15-30 seconds | Clears combustion chamber and checks for blockages. |

| Ignitor Warm-up & Gas Valve Activation | 5-10 seconds | Prepares and ignites the gas supply. |

| Heat Exchanger Warm-up | 30-60 seconds | Heats the core component that warms your home's air. |

| Blower Fan Engages | 30-90 seconds total | Circulates warm air through your vents. |

Is your furnace taking too long to warm up or showing signs of a problem?

Don't let a malfunctioning furnace compromise your comfort or safety. The experts at KINTEK understand the precise operation of heating systems. We provide reliable lab equipment and consumables that help HVAC professionals diagnose and service furnaces accurately.

If you're a technician needing precise tools or a lab researching heating efficiency, KINTEK supports your work. Contact our team today to learn how our products can help you ensure optimal furnace performance and safety.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Can calcination be done in a muffle furnace? Yes, for precise air-atmosphere heating.

- What are the safety precautions for heat treatment? A Complete Guide to Protecting Personnel and Facilities

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What are the three types of furnaces? Choose the Right Furnace for Your Needs

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application