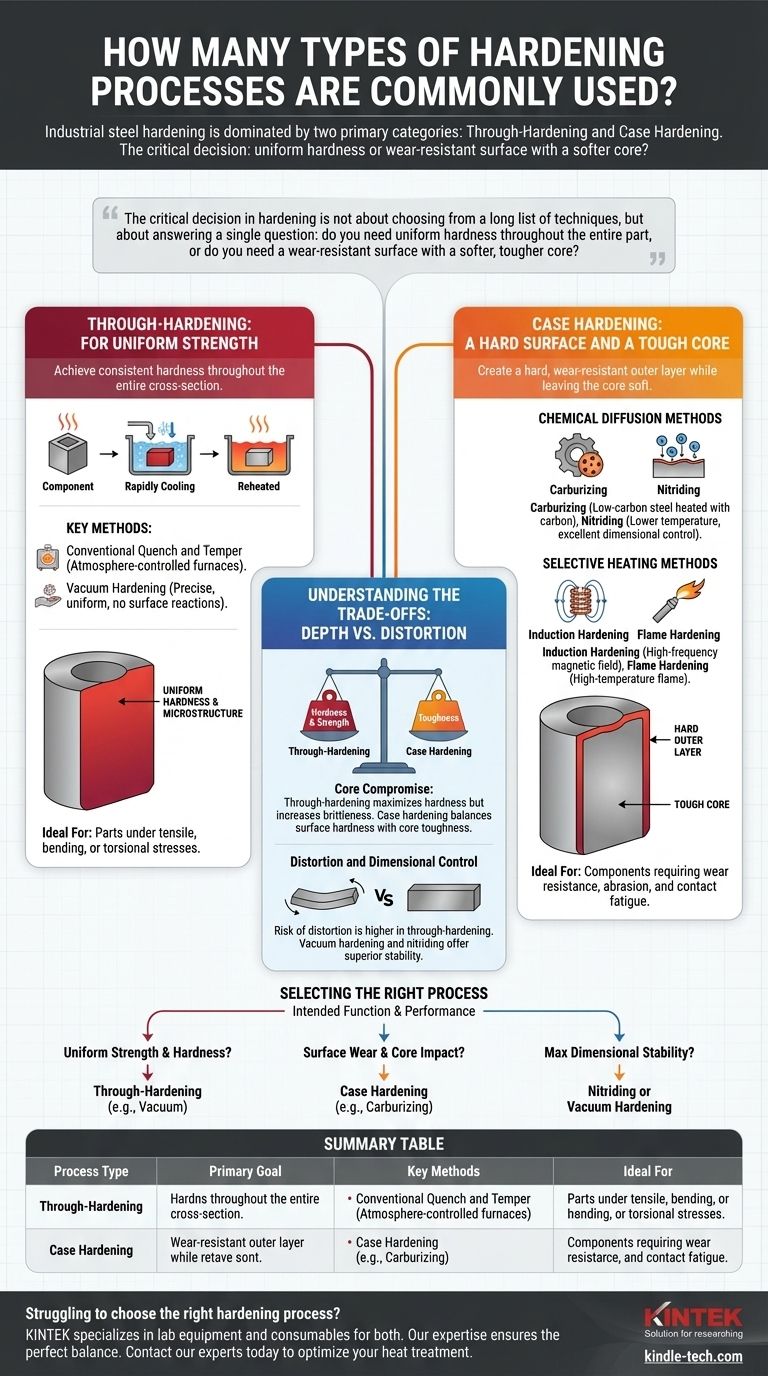

At its core, industrial steel hardening is dominated by two primary categories of processes: through-hardening and case hardening. While numerous specialized variations exist, nearly all common methods fall into one of these two families, differentiated by whether they harden the entire component or just its surface layer.

The critical decision in hardening is not about choosing from a long list of techniques, but about answering a single question: do you need uniform hardness throughout the entire part, or do you need a wear-resistant surface with a softer, tougher core?

Through-Hardening: For Uniform Strength

Through-hardening, also known as quench and tempering, aims to achieve a consistent hardness and microstructure throughout the entire cross-section of a component. This is ideal for parts subjected to tensile, bending, or torsional stresses that are distributed through the body of the part.

What It Is

The process involves heating the entire steel component above its critical transformation temperature and then cooling it rapidly (quenching) in a medium like oil, water, or gas. This rapid cooling locks in a very hard, brittle crystal structure called martensite. A subsequent tempering step (reheating to a lower temperature) is almost always required to reduce brittleness and improve toughness.

Key Method: Conventional Quench and Temper

This is the classic hardening process performed in atmosphere-controlled furnaces. It is a cost-effective and widely understood method for achieving high strength in a variety of alloy steels.

Key Method: Vacuum Hardening

As noted, this process is conducted in a vacuum furnace. The primary benefit is that the absence of oxygen prevents surface reactions, resulting in a bright, clean part with no surface decarburization.

The controlled environment also allows for extremely precise temperature control and uniform heating, which minimizes distortion. Quenching is typically done using high-pressure inert gas, like nitrogen, which is less severe than liquid quenching and further reduces the risk of cracking or warping.

Case Hardening: A Hard Surface and a Tough Core

Case hardening, or surface hardening, creates a hard, wear-resistant outer layer (the "case") while leaving the interior, or "core," of the component soft and ductile. This dual-property profile is perfect for components that must resist surface wear, abrasion, and contact fatigue while also withstanding impact and shock loads without fracturing.

Chemical Diffusion Methods

These processes alter the chemistry of the steel's surface by diffusing elements into it at high temperatures.

Carburizing is a widely used method where low-carbon steel is heated in an environment rich in carbon. The carbon diffuses into the surface, which can then be quenched and tempered to create a hard, high-carbon case over a tough, low-carbon core.

Nitriding involves diffusing nitrogen into the surface of the steel. This process is performed at lower temperatures than carburizing and does not require quenching, resulting in minimal distortion and excellent dimensional control. The resulting nitride case is extremely hard and wear-resistant.

Selective Heating Methods

These methods harden the surface by rapidly heating only the outer layer, followed by quenching. The core's chemistry and properties remain unchanged.

Induction hardening uses a high-frequency alternating magnetic field to rapidly generate heat at the surface of a part. Once the surface reaches the correct temperature, the power is shut off and the part is immediately quenched. It is a very fast, clean, and controllable process.

Flame hardening uses a high-temperature flame from a torch to heat the surface of the component. Once the desired temperature is reached, the surface is quenched. It is a more manual process but is versatile and well-suited for very large or non-uniform parts.

Understanding the Trade-offs: Depth vs. Distortion

Choosing the right process requires understanding the inherent compromises between different metallurgical outcomes.

The Core Compromise: Hardness vs. Toughness

This is the most fundamental trade-off in metallurgy. Through-hardening maximizes hardness and strength but increases brittleness. Case hardening intentionally creates a composite, balancing surface hardness with core toughness.

Distortion and Dimensional Control

Any process involving heating and rapid quenching introduces stress and carries a risk of distortion. Through-hardening, which affects the entire part, generally has a higher risk of warping compared to case hardening.

Processes like vacuum hardening and nitriding are prized for their superior dimensional stability due to more uniform heating and less severe or no quenching.

Cost and Application

Through-hardening is often simpler and more cost-effective for parts where uniform properties are needed. Case hardening processes can be more complex and expensive but are essential for high-performance components like gears, bearings, and crankshafts that require tailored surface and core properties.

Selecting the Right Hardening Process

Your choice should be dictated entirely by the component's intended function and performance requirements.

- If your primary focus is uniform strength and hardness to resist bending or tensile loads: Choose a through-hardening process like conventional quench and temper or, for higher precision, vacuum hardening.

- If your primary focus is surface wear resistance combined with core impact strength: Choose a case hardening process like carburizing for high loads or induction hardening for speed and precision.

- If your primary focus is maximum dimensional stability and minimal distortion is a must: Prioritize nitriding for case hardening or vacuum hardening for through-hardening applications.

Understanding this fundamental distinction between hardening the entire part versus only its surface is the key to specifying the correct treatment for your material's performance goals.

Summary Table:

| Process Type | Primary Goal | Key Methods | Ideal For |

|---|---|---|---|

| Through-Hardening | Uniform hardness throughout the part | Quench & Temper, Vacuum Hardening | Parts under tensile, bending, or torsional stress |

| Case Hardening | Hard surface, tough core | Carburizing, Nitriding, Induction, Flame Hardening | Gears, bearings, components needing wear resistance and impact strength |

Struggling to choose the right hardening process for your components? KINTEK specializes in providing the precise lab equipment and consumables needed for both through-hardening and case hardening applications. Our expertise ensures you achieve the perfect balance of hardness, toughness, and dimensional stability for your materials. Contact our experts today to discuss your specific requirements and let us help you optimize your heat treatment process for superior performance.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost