While there is no official, universally agreed-upon number, quenching methods are best understood by their process and the medium used. The key is not to memorize a list, but to understand how each technique manipulates the cooling rate to achieve specific metallurgical properties in the material, primarily steel. Common methods include direct, interrupted, selective, and spray quenching, each serving a distinct engineering purpose.

The core principle of quenching is not just rapid cooling, but controlled cooling. The choice of method is a deliberate trade-off between achieving maximum hardness and minimizing internal stress, distortion, and the risk of cracking.

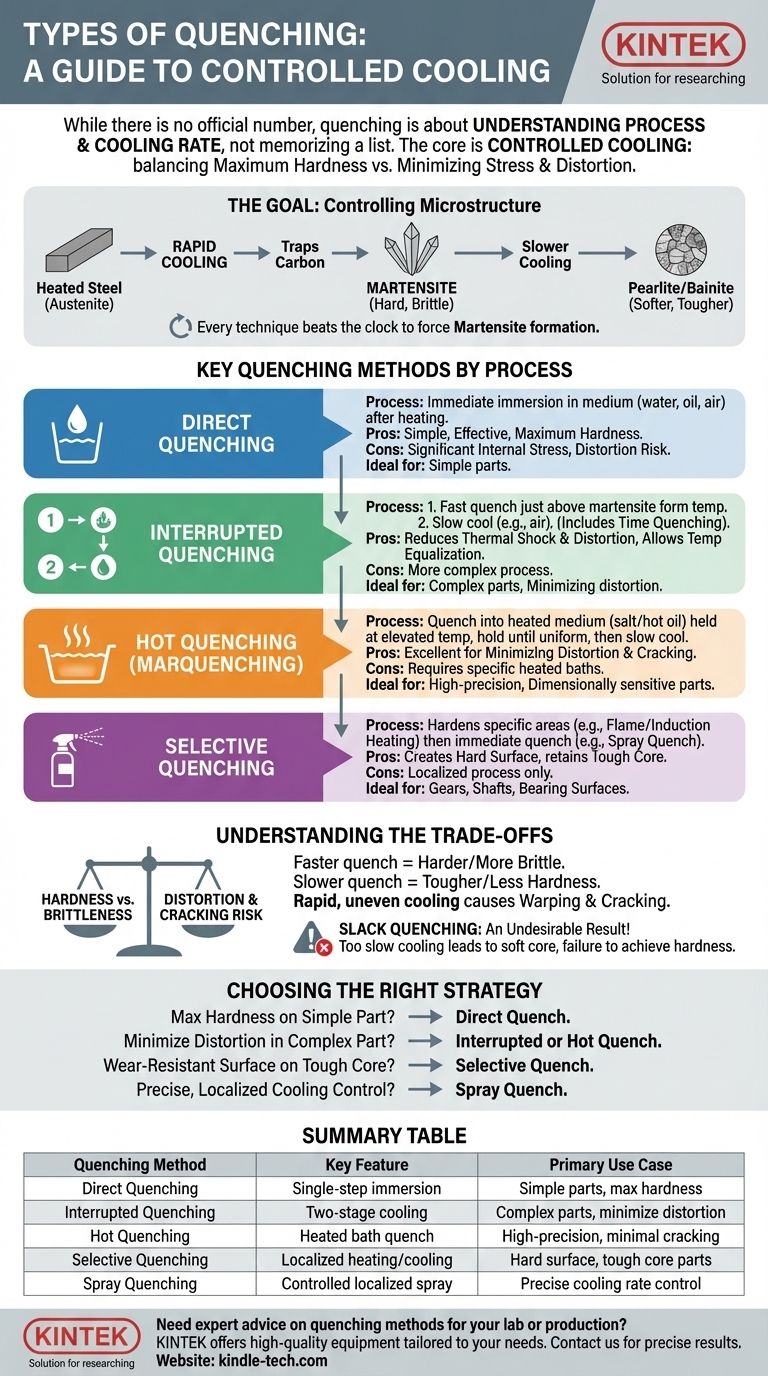

The Goal of Quenching: Controlling Microstructure

Before categorizing the types, it's crucial to understand the "why." When steel is heated to its austenitizing temperature, its crystal structure changes. The goal of quenching is to cool it so rapidly that it cannot revert to its softer, pre-heated structures.

Forcing a Martensitic Transformation

The rapid cooling traps carbon atoms within the iron crystal lattice, a hard, brittle, and needle-like structure called martensite. This is what gives quenched steel its signature hardness and strength.

Slower cooling would allow the steel to form softer structures like pearlite or bainite. Therefore, every quenching technique is a strategy to "beat the clock" and force the formation of martensite.

Key Quenching Methods by Process

The various types of quenching are best grouped by the process used to control the cooling curve.

Direct Quenching

This is the most straightforward method. The part is cooled immediately in a quenching medium (like water, oil, or air) after being heated or hot-worked (e.g., forging). It is simple and effective but can introduce significant internal stress.

Interrupted Quenching

This is a two-stage process designed to reduce thermal shock and distortion. The part is first quenched in a fast medium to a temperature just above where martensite begins to form. It is then removed and cooled slowly in a second medium, like air.

This pause allows the temperature to equalize between the surface and the core of the part, drastically reducing stress before the final, brittle martensitic transformation occurs. Time Quenching is a form of interrupted quenching where the part is held in the initial quenchant for a precisely controlled duration.

Hot Quenching

Also known as marquenching or martempering, this involves quenching the part into a medium held at an elevated temperature, typically a molten salt or hot oil bath. The part is held at this temperature until it is uniform throughout, then cooled slowly in air.

Like interrupted quenching, this method is excellent for minimizing distortion and cracking in complex or dimensionally sensitive parts.

Selective Quenching

This method hardens only specific areas of a component. Techniques like flame hardening or induction hardening heat only a portion of the part's surface, which is then immediately quenched, often by a spray quench.

This leaves the core of the part tough and ductile while creating a hard, wear-resistant surface. This is common for gears, shafts, and bearing surfaces.

Understanding the Trade-offs

Choosing a quenching method is never about finding the "best" one, but the most appropriate one for the material and the desired outcome.

The Hardness vs. Brittleness Dilemma

A faster quench produces a harder, more martensitic structure. However, this also increases brittleness. An aggressive water or brine quench creates extreme hardness but also extreme internal stress, making the part susceptible to cracking. A slower oil quench may result in slightly less hardness but significantly more toughness.

The Risk of Distortion and Cracking

Rapid, uneven cooling is the primary cause of warping and cracking. The surface of a part cools and contracts much faster than its core, creating immense internal tension. Methods like interrupted and hot quenching are specifically designed to combat this problem by allowing temperatures to equalize before the final transformation.

What is Slack Quenching?

"Slack Quenching" is not a process you choose, but an undesirable result. It occurs when the cooling rate is too slow to fully transform the part's core into martensite. This results in a "slack" or soft core, failing to achieve the desired hardness throughout the component's cross-section.

Choosing the Right Quenching Strategy

Your choice depends entirely on the component's material, its geometry, and its intended application.

- If your primary focus is maximum hardness on a simple part: A direct quench in a fast medium like water or brine is often sufficient.

- If your primary focus is minimizing distortion in a complex part: Interrupted or hot quenching are the superior choices to manage thermal stress.

- If your primary focus is creating a wear-resistant surface on a tough core: Selective quenching is the designated method for the job.

- If you need precise, localized cooling control: A spray or fog quench offers more command over the cooling rate than simple immersion.

Ultimately, effective quenching is a balancing act between achieving the desired metallurgical properties and maintaining the physical integrity of the part.

Summary Table:

| Quenching Method | Key Feature | Primary Use Case |

|---|---|---|

| Direct Quenching | Single-step immersion in a medium (water, oil) | Simple parts requiring maximum hardness |

| Interrupted Quenching | Two-stage cooling to reduce stress | Complex parts where minimizing distortion is critical |

| Hot Quenching (Marquenching) | Quenching into a heated bath (salt, oil) | High-precision parts needing minimal cracking risk |

| Selective Quenching | Localized heating and cooling (e.g., flame hardening) | Parts requiring a hard surface and a tough core (gears, shafts) |

| Spray Quenching | Controlled, localized cooling via spray nozzles | Applications needing precise cooling rate control |

Need expert advice on selecting the right quenching method for your laboratory or production needs? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your material processing challenges. Whether you're working on heat treatment research, quality control, or production hardening, our team can help you choose the right tools to achieve precise results. Contact us today to discuss how our solutions can enhance your processes and ensure consistent, high-quality outcomes for your steel components.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing