The short answer is that a biomass pyrolysis reactor's cost varies dramatically, from tens of thousands of dollars for a small lab-scale unit to tens of millions for a large, industrial-scale facility. The price is dictated by its processing capacity, the specific pyrolysis technology used, the level of automation, and the required ancillary equipment for feedstock preparation and product collection.

The cost of the pyrolysis reactor itself is often just one component of the total project expense. To create a realistic budget, you must consider the cost of the entire integrated system, from feedstock handling and drying to product upgrading and storage.

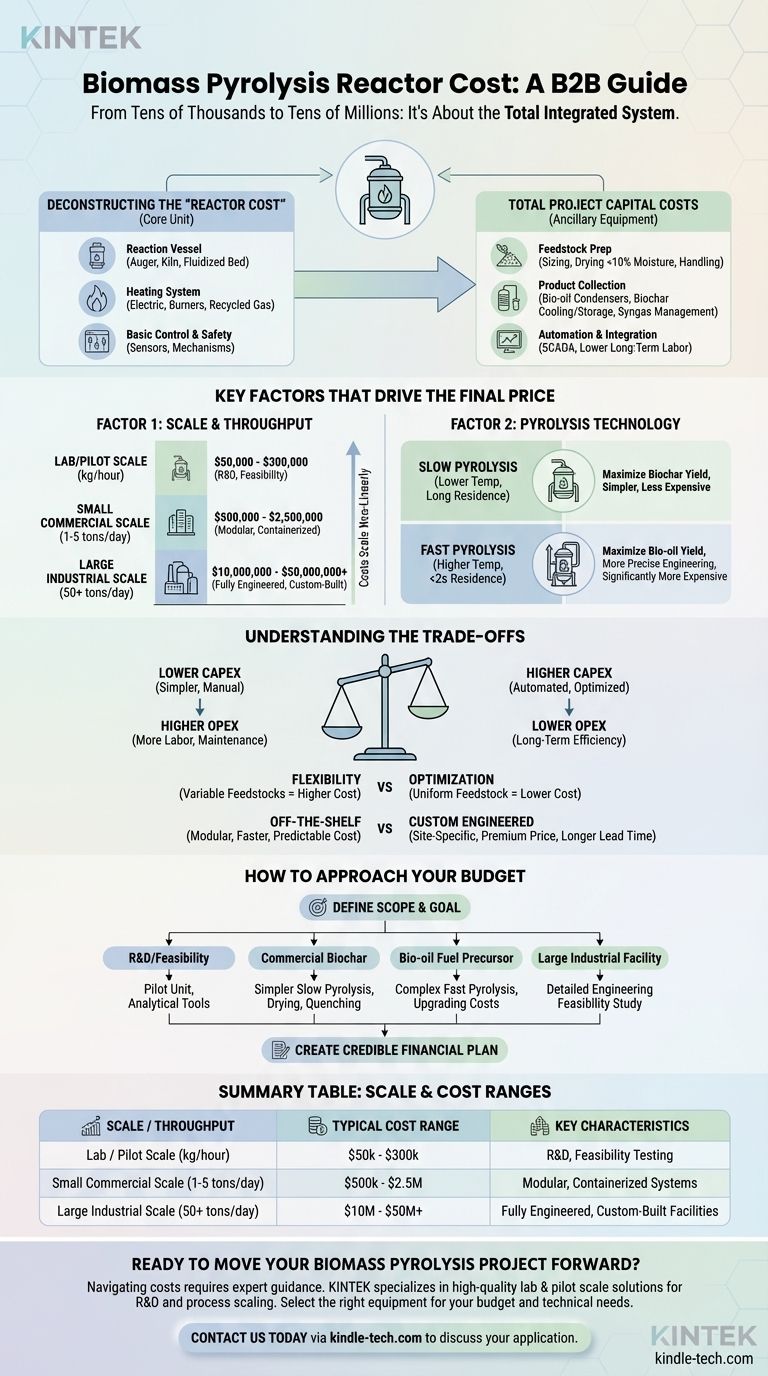

Deconstructing the "Reactor Cost"

When you receive a quote for a "pyrolysis reactor," it's critical to understand what is included. The core reactor is the heart of the system, but it's not the whole system.

The Core Reactor Unit

The central component is the reaction vessel where the biomass is heated in the absence of oxygen. The design of this vessel—such as an auger, rotary kiln, or fluidized bed—is a primary cost driver.

The Heating System

The method for delivering heat is a significant cost factor. This can range from external electric heaters or gas burners to more complex systems that recycle the non-condensable gases produced during pyrolysis to fuel the process.

Basic Control and Safety

At a minimum, the price will include basic temperature and pressure sensors, along with essential safety mechanisms. This ensures the unit can operate within its designed parameters.

Beyond the Reactor: Total Project Capital Costs

Focusing only on the reactor is like pricing a car engine without considering the cost of the car. The ancillary equipment required for a complete, functioning plant often equals or exceeds the cost of the reactor itself.

Feedstock Preparation System

Biomass rarely arrives ready for pyrolysis. This upstream equipment is a major expense.

- Sizing: Grinders or chippers are needed to reduce the biomass to a consistent particle size.

- Drying: Most pyrolysis processes require feedstock with low moisture content (typically <10%). Industrial dryers are large, energy-intensive, and expensive.

- Handling: Conveyors, hoppers, and feeding mechanisms are needed to move the material into the reactor.

Product Collection and Upgrading

The outputs of pyrolysis—bio-oil, biochar, and syngas—are not immediately ready for market. This downstream processing adds significant cost.

- Bio-oil Collection: A series of condensers and electrostatic precipitators may be needed to capture and separate the liquid bio-oil.

- Biochar Handling: A system for cooling (quenching), collecting, and storing the hot biochar is essential for safety and product quality.

- Syngas Management: The non-condensable gas must be either flared, cleaned for use as fuel, or refined for other applications.

Automation and Integration

A fully automated plant operating with a sophisticated SCADA (Supervisory Control and Data Acquisition) system will have a much higher initial cost than a manually operated batch system. However, it will have lower long-term labor costs.

Key Factors That Drive the Final Price

Four main variables will determine the final cost of your pyrolysis project.

Factor 1: Scale and Throughput

This is the single biggest driver. Costs scale non-linearly with size.

- Lab/Pilot Scale (kg/hour): $50,000 - $300,000. These are for research and feasibility testing.

- Small Commercial Scale (1-5 tons/day): $500,000 - $2,500,000. Often modular and containerized.

- Large Industrial Scale (50+ tons/day): $10,000,000 - $50,000,000+. These are fully engineered, site-built facilities.

Factor 2: Pyrolysis Technology

The type of reactor technology has a major impact on complexity and cost.

- Slow Pyrolysis: Operates at lower temperatures with longer residence times to maximize biochar yield. These systems are generally simpler, more robust, and less expensive.

- Fast Pyrolysis: Operates at higher temperatures with very short residence times (<2 seconds) to maximize bio-oil yield. These systems require more precise engineering, sophisticated heat transfer, and are significantly more expensive.

Understanding the Trade-offs

Choosing a pyrolysis system involves balancing competing priorities. There is no single "best" option, only the best fit for your specific goal and budget.

CAPEX vs. OPEX

A lower initial capital expenditure (CAPEX) might come from a simpler, manually operated system. However, this system will likely have higher operating expenditures (OPEX) due to increased labor needs, lower efficiency, and potentially higher maintenance. An expensive, fully automated system is designed to minimize OPEX over the long term.

Flexibility vs. Optimization

A reactor designed to process a single, uniform feedstock (e.g., kiln-dried wood chips) can be highly optimized and less expensive. A system designed to handle variable feedstocks (e.g., municipal solid waste, agricultural residues) requires more complex pre-processing and controls, increasing its cost.

Off-the-Shelf vs. Custom Engineered

For smaller scales, standardized, modular systems offer a predictable cost and faster deployment. For large-scale industrial applications, a custom-engineered solution is almost always necessary to integrate with the specific site, feedstock, and product requirements, which comes at a premium price and longer lead time.

How to Approach Your Budget

To get a realistic cost estimate, you must first define the scope and goal of your project.

- If your primary focus is R&D or feasibility testing: Look for a small-scale pilot unit and budget for the core system plus basic analytical tools.

- If your primary focus is commercial biochar production: You can likely specify a simpler and less expensive slow pyrolysis system, but do not forget to budget for feedstock drying and biochar quenching/packaging.

- If your primary focus is producing bio-oil as a fuel precursor: You must budget for a more complex fast pyrolysis system and include significant costs for downstream bio-oil collection and upgrading.

- If you are planning a large industrial facility: Your first step is not to price a reactor, but to commission a detailed engineering feasibility study that defines the entire system from end to end.

Ultimately, defining your project's inputs, desired outputs, and scale is the only way to transform a vague price range into a credible financial plan.

Summary Table:

| Scale / Throughput | Typical Cost Range | Key Characteristics |

|---|---|---|

| Lab / Pilot Scale (kg/hour) | $50,000 - $300,000 | For research, development, and feasibility testing. |

| Small Commercial Scale (1-5 tons/day) | $500,000 - $2,500,000 | Often modular, containerized systems. |

| Large Industrial Scale (50+ tons/day) | $10,000,000 - $50,000,000+ | Fully engineered, custom-built facilities. |

Ready to move your biomass pyrolysis project forward?

Navigating the complex costs of pyrolysis systems requires expert guidance. KINTEK specializes in providing high-quality lab equipment and consumables, serving the precise needs of laboratories and pilot plants. Whether you are conducting R&D or scaling up your process, our expertise can help you select the right equipment to fit your budget and technical requirements.

Contact us today via our contact form to discuss your specific application and discover how KINTEK can support your innovation with reliable, efficient solutions.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Performance Laboratory Freeze Dryer for Research and Development

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy