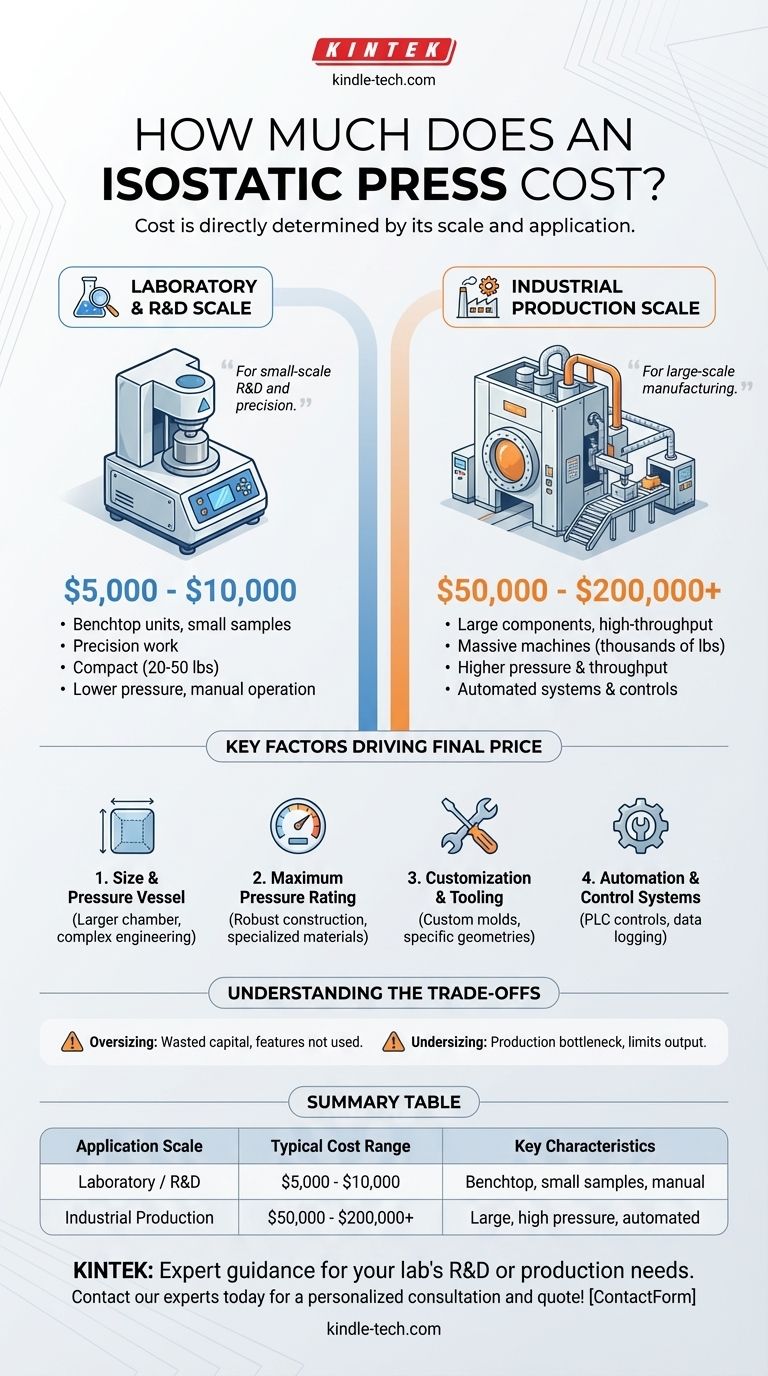

The cost of an isostatic press is directly determined by its scale and application. A benchtop Cold Isostatic Press (CIP) designed for laboratory samples typically costs between $5,000 and $10,000, while large industrial CIP systems for manufacturing environments range from $50,000 to over $200,000.

The price of an isostatic press is not about the technology itself, but about its application. The fundamental divide is between small-scale R&D and large-scale industrial production, which dictates the machine's size, pressure capabilities, and ultimately, its cost.

The Two Tiers of Isostatic Press Costs

The market for isostatic presses is clearly divided into two distinct categories based on intended use. Understanding which category you fall into is the first step in estimating your budget.

Laboratory and R&D Scale

These benchtop units are designed for precision work on small, lab-scale samples. They are compact, often weighing between 20 and 50 pounds, making them suitable for research environments.

The price for these models falls in the $5,000 to $10,000 range. The final cost depends on specific requirements like maximum pressure and chamber size.

Industrial Production Scale

Industrial Cold Isostatic Pressing (CIP) systems are built for manufacturing large components or high-throughput production. These are massive machines, often weighing thousands of pounds.

The investment for these systems is significantly higher, starting at $50,000 and easily exceeding $200,000. The price increases with size, pressure, and the level of automation required.

Key Factors Driving the Final Price

While the primary distinction is lab versus industrial, several key factors influence the final price within each category.

Size and Pressure Vessel

The most significant cost driver is the size of the pressure vessel. A larger chamber to accommodate bigger parts requires more material and more complex engineering to safely contain the high pressures involved.

Maximum Pressure Rating

Higher pressure capabilities demand more robust construction, specialized materials, and more powerful pumping systems. As the pressure requirement (PSI or Bar) increases, so does the cost of the machine.

Customization and Tooling

Any deviation from a standard model will add to the cost. This includes custom-designed molds or tooling to form specific part geometries, as well as modifications to the press itself.

Automation and Control Systems

Industrial systems often require automation for loading/unloading parts and sophisticated PLC controls for process monitoring and data logging. These features add considerable expense but are essential for production efficiency and quality control.

Understanding the Trade-offs

Choosing the wrong scale of press is a costly mistake. It's critical to evaluate not just your current needs but also your future goals.

The Cost of Oversizing

Purchasing an industrial-scale press for R&D work is a significant misallocation of capital. You pay a premium for capacity and features you will not use, while also incurring higher installation and operating costs.

The Limitation of Undersizing

A lab-scale press cannot meet the demands of a production environment. Attempting to use it for manufacturing will create a severe bottleneck, limiting output and preventing your operation from scaling effectively.

Beyond the Sticker Price

Remember that the initial purchase price is only part of the total cost of ownership. You must also budget for installation, operator training, ongoing maintenance, and potential tooling costs for new parts.

Making the Right Choice for Your Goal

Your decision must be guided by a clear understanding of your primary objective.

- If your primary focus is research and development: A benchtop model in the $5,000 to $10,000 range provides the necessary precision without the high cost of an industrial system.

- If your primary focus is large-scale or high-volume manufacturing: You must budget for an industrial system starting at $50,000, with the final cost determined by your specific size and automation needs.

Matching the press's scale to your application's true requirements is the key to making a sound investment.

Summary Table:

| Application Scale | Typical Cost Range | Key Characteristics |

|---|---|---|

| Laboratory / R&D | $5,000 - $10,000 | Benchtop units, small samples, lower pressure, manual operation |

| Industrial Production | $50,000 - $200,000+ | Large chambers, high pressure & throughput, automated systems |

Ready to find the perfect isostatic press for your lab's R&D or production needs?

KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the right press for your specific application and budget. We ensure you get the performance you need without overspending.

Contact our experts today for a personalized consultation and quote!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the difference between hot isostatic pressing and cold isostatic pressing? A Guide to Forming vs. Densification

- What are the different types of cold isostatic pressing? Wet-Bag vs. Dry-Bag for Your Production Needs

- Why Use Cold Isostatic Press (CIP) for MgAl2O4 After Dry Pressing? Achieve Flawless Transparency

- How does an isostatic work? Achieve Uniform Density and Complex Shapes with Isostatic Pressing

- What is the role of a Cold Isostatic Press (CIP) in C-PSC lamination? Enhance Solar Efficiency Without Heat

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- What is the pressure for isostatic pressing? Unlock the Key to Uniform Material Densification

- Why is a cold isostatic press advantageous for Argyrodite sulfide solid-state batteries? Achieve Optimal Densification