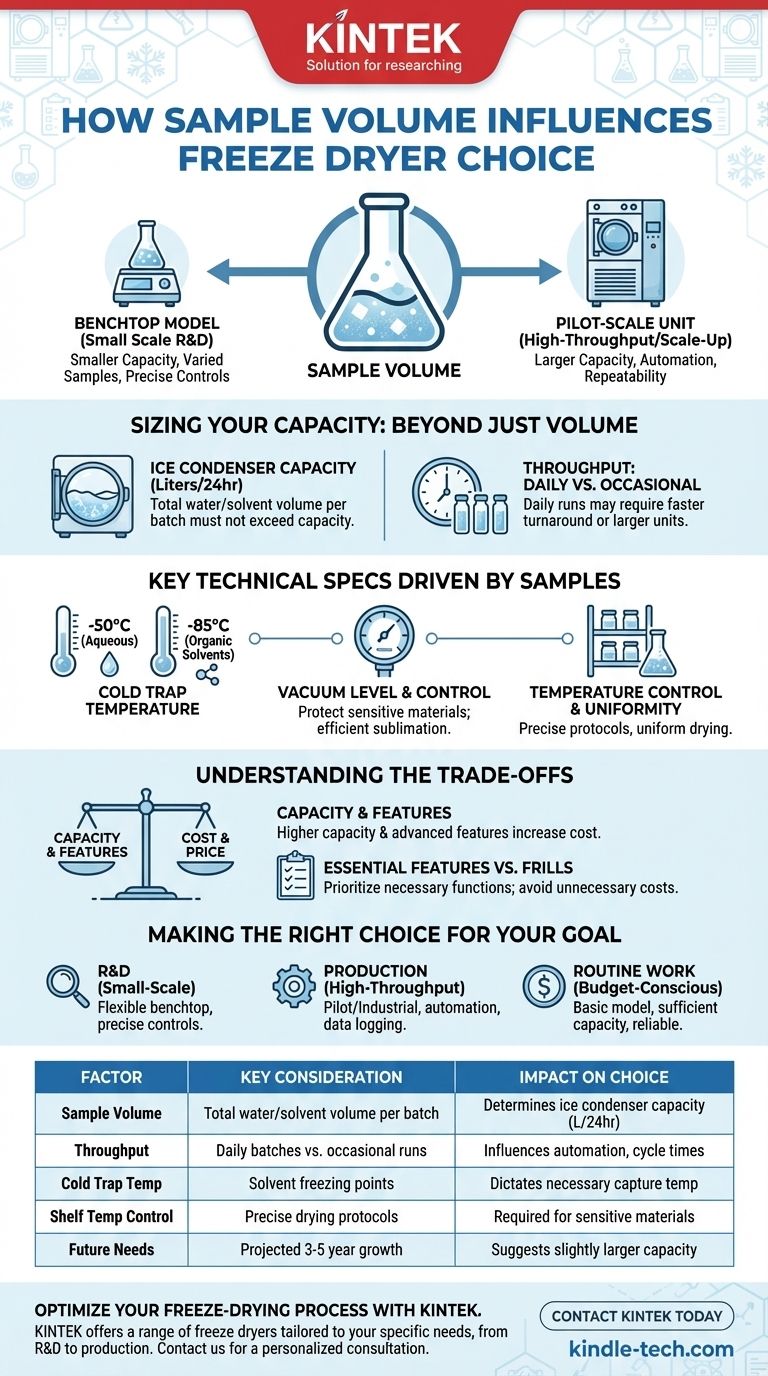

Choosing the right lab freeze dryer begins with a direct assessment of your sample volume. The total volume of material you process in a single cycle is the primary factor determining the required capacity of the machine, directly influencing whether a small benchtop model or a larger pilot-scale unit is appropriate for your needs.

While sample volume determines the initial size and capacity you should consider, the truly optimal choice balances this against your specific applications, required process controls, and realistic future throughput demands.

Sizing Your Capacity: Beyond Just Volume

Thinking about capacity correctly involves more than the physical size of your samples. It requires a deeper look into the nature of your work and your operational rhythm.

From Sample Volume to Ice Capacity

The most critical capacity specification is the ice condenser capacity, typically measured in liters. This tells you the maximum amount of water (or solvent) the machine can trap as ice in a single 24-hour period.

You must calculate the total volume of water in your largest batch of samples to ensure it does not exceed the condenser's capacity. Overloading the condenser is a primary cause of process failure.

Throughput: Daily Batches vs. Occasional Runs

Your required throughput is as important as your batch size. A lab running multiple small batches every day has different needs than a lab running one large batch per week.

High throughput may justify a larger unit to consolidate runs or a model with faster turnaround times, even if individual sample volumes are small.

Projecting Future Needs

A freeze dryer is a significant capital investment. It is crucial to consider not only your current needs but also your projected needs over the next 3-5 years.

Purchasing a unit with slightly more capacity than you currently require can prevent the costly problem of outgrowing your equipment as your research or production scales up.

Key Technical Specifications Driven by Your Samples

Once you have a general capacity in mind, the specific nature of your samples will dictate the technical features you need. Volume sets the scale, but your application defines the necessary precision.

Cold Trap Temperature

The required cold trap temperature is determined by the freezing point of the solvents in your sample. Standard aqueous samples are served well by -50°C traps, but samples containing organic solvents with low freezing points demand colder traps (-85°C or lower) to be captured effectively.

Vacuum Level and Control

The level of vacuum and the precision of its control are critical for protecting sensitive biological materials or complex formulations. Different products require different vacuum pressures to sublimate efficiently without collapsing the product structure.

Temperature Control and Uniformity

For many applications, especially in pharmaceutical development, the ability to precisely control shelf temperature is non-negotiable. This feature allows you to execute specific, repeatable drying protocols and ensures uniformity across all samples in the batch.

Understanding the Trade-offs

Selecting a freeze dryer involves balancing performance, features, and budget. Being aware of the key trade-offs is essential for making a sound investment.

Capacity vs. Cost

There is a direct and significant correlation between capacity and price. Larger units with greater ice condenser and shelf capacity are more complex to manufacture and command a much higher price.

Essential Features vs. Unnecessary Frills

Advanced features like automatic process controls, sophisticated data logging for regulatory compliance, and specialized accessories all increase cost. You must prioritize features that are essential for your work rather than paying for capabilities you will never use.

Manufacturer Reputation and Reliability

Established brands with a proven history of quality and support often have higher initial costs. This premium often translates into greater reliability, better application support, and readily available service, mitigating the risk of expensive downtime.

Making the Right Choice for Your Goal

Filter your options through the lens of your primary objective to clarify your decision.

- If your primary focus is small-scale R&D with varied samples: Prioritize a flexible benchtop model with precise temperature and vacuum controls to accommodate a wide range of products.

- If your primary focus is high-throughput production or scale-up: Invest in a larger pilot or industrial model where automation, data logging, and process repeatability are the most critical features.

- If your primary focus is budget-conscious routine work: Select a basic model with sufficient ice capacity from a reputable manufacturer, avoiding advanced features you do not need.

By looking beyond simple volume to your core processes, you ensure your freeze dryer becomes a long-term asset, not a short-term limitation.

Summary Table:

| Factor | Key Consideration | Impact on Choice |

|---|---|---|

| Sample Volume | Total water/solvent volume per batch | Determines required ice condenser capacity (liters/24hr) |

| Throughput | Daily batches vs. occasional runs | Influences need for automation and faster cycle times |

| Cold Trap Temp | Solvent freezing points (e.g., -50°C vs. -85°C) | Dictates necessary temperature for effective solvent capture |

| Shelf Temp Control | Need for precise, repeatable drying protocols | Required for sensitive materials like pharmaceuticals |

| Future Needs | Projected 3-5 year growth | Suggests buying slightly larger capacity to avoid obsolescence |

Optimize your freeze-drying process with KINTEK.

Choosing the right lab freeze dryer is critical for the success of your research or production. KINTEK specializes in providing high-quality lab equipment and consumables, offering a range of freeze dryers tailored to different sample volumes and applications—from flexible benchtop units for R&D to automated pilot-scale systems for high-throughput work.

Our experts can help you analyze your specific needs—including ice capacity, cold trap temperature, and throughput—to ensure you select a machine that fits your budget and grows with your lab. Avoid costly downtime and ensure process repeatability with a reliable partner.

Contact KINTEK today for a personalized consultation and let us help you make the perfect choice for your laboratory's needs.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the different freeze drying methods? Choose the Right Lyophilization Path

- What is the basic process of freeze drying? A Guide to Lyophilization Stages and Benefits

- What are the overall benefits of freeze drying technology across industries? Achieve Unparalleled Product Preservation

- What types of products are not suitable for freeze drying? Avoid These Common Freeze-Drying Failures

- How does a freeze dryer work? Preserve Delicate Materials with Sublimation